The business environment has become very competitive, and many firms are now under pressure to come up with innovative management ideas in order to remain competitive in the market. Enterprise resource planning is one of the innovative ideas that many firms are currently using to achieve efficiency in their operations. This system enables a firm to manage data from various business activities and integrate it in order to make the work of the managers easy. Enterprise resource planning makes it possible to collect, analyse and store data on various activities within a given firm. According to Taylor (29), enterprise resource planning has gained relevance in the supply chain management. Lawson ERP supply chain module is one of the popular supply chain modules which are currently in use. This research will focus on the role of supply chain management module Lawson ERP system.

Lawson ERP supply chain module has become one of the most favourite supply chain management systems that firms are using to gain a competitive edge over their market rivals (Bolstorff 58). This EPR module offers two different products which are M3 and S3. The letters S means service and M means make. The S series products were developed specifically for the service industry to help in sourcing, staffing and serving (Blissett 76). It majorly targets industries such as retail, financial, and the health sector. The main advantage of this module is that it enables the users to monitor the stages of various services meant for the customers. For instance, the management of a hospital can easily monitor the time taken to offer services to a client at every department of the facility. It will know the time the patient takes at the registration, with the doctor, at the laboratory, and at the pharmacy. This way, it will be easy to know if the departments are delivering the value desired by the firm. The major disadvantage of this product is that it has not been very effective among the large manufactures operating in the global market.

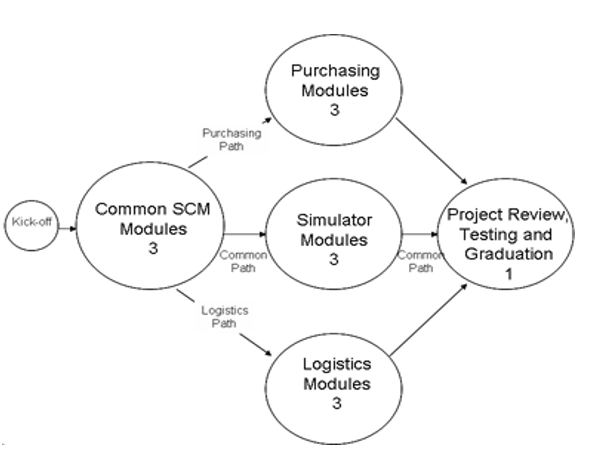

The M3 series category was specifically developed for industries that majorly make, maintain, or move processes. The product has been very beneficial for large manufacturing firms, especially those that have global markets coverage. According to Leon (18), M3 series products play an important role in the supply chain management. These two unique series are what differentiates Lawson ERP from other systems that are offered by other vendors. Blissett (89) says, “Lawson Supply Chain Management is an integrated procurement and distribution solution.” The main advantage of this system is that it helps in lowering the cost by enhancing processes in the supply chain through effective management. According to Leon (41), Lawson ERP System enhances the process of management by enabling it to have full control of the purchasing processes and expenses. It also extends the value of the supply chain within a firm. One unique feature of this system that makes it different from other supply chain modules is that it enables the manager to monitor various activities within the supply chain without necessarily leaving the office. The following diagram shows the steps in Lawson ERP supply chain management module.

As shown in the above diagram, Lawson ERP Supply Chain Module 3 defines three paths from the kick off. There is the purchasing path that leads to the purchasing modules. Then there is the logistics path that leads to the logistics modules. Each of these two modules has very specific tasks that must be planned for in order to achieve the desired results. On the purchasing path, this module emphasises on the need to identify the best options in the market before making the purchasing decision. On the logistics path, it defines the kind of equipment that should be used, how the activities should be coordinated, and the parties involved in this process. On the common path that leads to simulator module, the system defines how all the processes within the supply chain should be integrated through an effective communication system. All these three paths converge at the review and testing stage where the stakeholders will determine if the system has delivered the expected outcome.

According to Taylor (115), the use of ERP system is very critical when handling internal supply chain activities. Once the raw materials have been purchased, the management will need to ensure that the materials are delivered to the manufacturing plant within the shortest time possible. Similarly, the manufactured products should be delivered to the market as soon as possible. This does not only eliminate the costs associated with wastes and breakage, but also lowers the cost of storage. In order to achieve this, it is necessary to have an integrated system of communication that will enhance coordination from one department to the other. Lawson ERP system offers the best solution. When used properly, it enhances control of the entire supply chain, and adds value to the production process.

Works Cited

Blissett, Guy. Facing the Forces of Change: Decisive Actions for an Uncertain Economy. Washington, D.C: NAW Institute for Distribution Excellence, 2010. Print.

Bolstorff, Paul. Supply chain excellence: A handbook for dramatic improvement using the SCOR model. New York: American Management Association, 2012. Print.

Leon, Alexis. ERP Demystified. New Delhi: Tata McGraw-Hill, 2013. Print.

Shah, Janat. Supply Chain Management: Text and Cases. Upper Saddle River: Pearson Education, 2009. Print.

Taylor, Daniel. Supply chains: A manager’s guide. Boston: Addison-Wesley, 2009. Print.