Introduction

All businesses, both manufacturing and service-driven, should draw specific attention to their operations. It is so because operations analysis can show existing inefficiencies and opportunities to improve supply chain performance. Thus, the given paper will present process maps of how products and services are created. The flow charts will reveal the similarities and differences between the manufacturing and service-driven companies, which will be useful to limit the effect of variabilities and achieve higher flexibility.

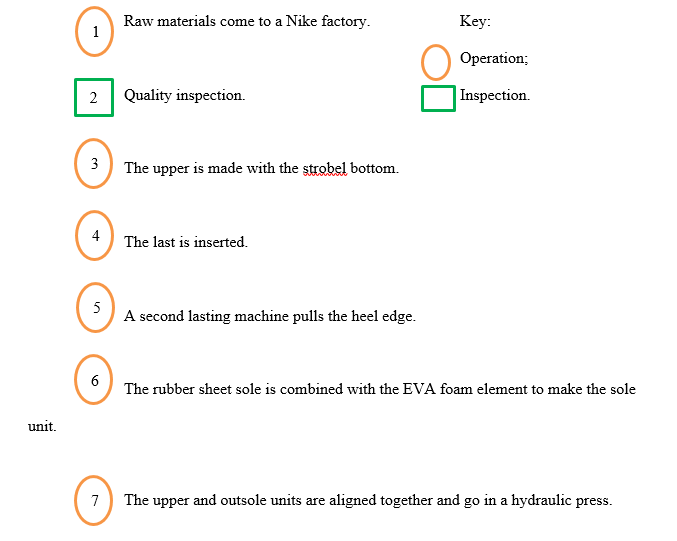

Manufacturing Process Map at Nike Factories

Nike is one of the most famous manufacturers of sportswear, and customers from various world countries use its finished goods. Jiang (2019) indicates that footwear is “the main product produced by Nike company” (p. 88). The flow chart above includes the principal elements of a Nike cold cement manufacturing process, described by The Sneaker Factory (2017). Here, every Nike factory should have facilities and necessary equipment, including a lasting machine, heating tunnels, cooling tunnels, and others. One should stipulate that the company draws significant attention to the quality of its raw materials, which makes it possible to produce the shoes of superior quality (Nike, 2017).

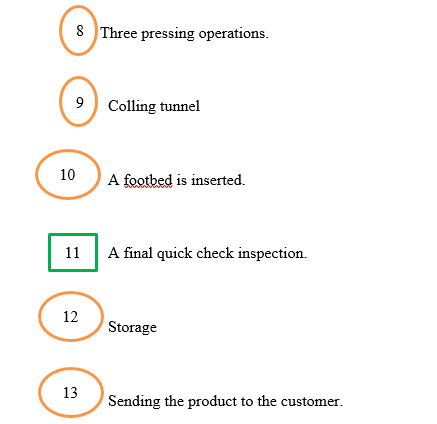

Service Process Map for Bank of America

Bank of America is one of the most popular financial institutions among US citizens. According to Silady (2020), the bank has approximately “$1.8 trillion in consolidated assets” (para. 4). That is why it is not a surprise that millions of Americans utilize its services. The flow chart above represents a simple service process map that is utilized when a customer wants to open a banking account. Thus, the customer’s demand is the primary driver of this situation. Bank of America (n.d.) stipulates that a customer should present their personal details to launch the course of actions. The Financial Brand (2019) emphasizes that the last step of the process is of significance because it can determine the customer’s satisfaction.

Summary

A careful analysis of the two flow charts above demonstrates that the manufacturing and service-driven companies have both similarities and differences. On the one hand, it is necessary to comment on shared features. Firstly, the two firms are customer-oriented, which means that they should provide their clients with cost attractive offerings. As for Nike, the company should get the raw materials at the lowest price possible, while Bank of America should keep indirect costs low to be competitive in the market. Secondly, the two businesses should invest in forecasting customer demand. If adequate, this information will make it possible for Bank of America to employ a suitable number of specialists and for Nike to produce shoes that will be attractive among clients.

On the other hand, the various specializations of the companies lead to significant differences. The leading one refers to the fact that it is impossible to store services or produce them in advance. Thus, a service-driven business should be ready to witness demand immediately when it arises, which emphasizes a dominant role of capacity (Jacobs & Chase, 2014). Furthermore, the manufacturing process above primarily relies on numerous pieces of equipment, while employees are one of the most significant assets for service-driven companies.

The final difference refers to the opportunity and readiness of the firms to change. It relates to the fact that a bank can easily change its offering in a single day (Jacobs & Chase, 2014). At the same time, to bring some changes is a challenging task for Nike because the flow chart has demonstrated that the manufacturing process consists of multiple interdependent operations. It is so because the Nike shoes are produced in an assembly line layout. Consequently, the implication of any modification will require many resources and efforts.

In addition to that, it is reasonable to identify a possible impact of customer-introduced variabilities on the companies. Nike does not suffer from these variabilities because the company’s manufacturing process does not imply direct contact with clients. As a result, consumers can only influence the producer by changing their demand peculiarities. At the same time, Bank of America, a service-driven business, cooperates with its customers directly to provide them with various services, which intensifies the role of variabilities.

As for the given case, arrival and request variabilities are essential. It is so because the bank cannot predict when customers will come and what additional services they will need. The best way for the bank to address these phenomena is to use reduction strategies (Jacobs & Chase, 2014). Firstly, it is possible to control customers’ arrivals by offering off-peak pricing. For example, a client will be given additional service if they come during appropriate periods. Secondly, limiting the service breadth will minimize the effect of request variability. When clients have fewer options to choose, the bank will find it easier to satisfy their demands.

It is impossible to deny that a deep understanding of both manufacturing and service environments is useful information. Firstly, it helps identify the most significant steps that constitute the processes of manufacturing or creating a service. As far as my future career is concerned, these data will allow me to manage and control operations. Secondly, it is reasonable to delve into service and manufacturing environments to determine inefficiencies and problems, if any.

When it comes to the Nike case, for example, there can be a situation that numerous customers emphasize the unsatisfactory quality of the footwear. Here, it is reasonable to consider the manufacturing process map to check each of the steps. Supposing that all the steps are performed adequately, and a final quick check inspection does not identify any defects, the problems can arise because of improper storage of the finished products. That is why a deep understanding of the environments under consideration is essential for my future career.

Conclusion

Process mapping is a significant element for every business, irrespective of whether it is manufacturing or service-driven. This phenomenon provides responsible individuals with useful information on how products or services are created, which helps identify operations inefficiencies and improve performance. The information above has demonstrated that the two process maps have both similarities and differences.

While the presence of some shared features is justified by the necessity to meet the customer’s demand, the discrepancies arise because the companies under analysis represent various specializations. That is why Bank of America, a service-driven company, is more subject to customer-introduced variabilities, which makes it develop appropriate strategies to address the issue. It has been shown that the available reduction strategies are a useful option to solve these problems.

References

Bank of America. (n.d.) Applying for Bank of America accounts FAQs. Web.

Financial Brand. (2019). Real-time feedback powers Band of America customer experience effort. Web.

Jacobs, F. R., & Chase, R. (2014). Operations and supply chain management (14th ed.). McGraw-Hill Education.

Jiang, W. (2019). Sustainable development of supply chain in footwear industry: Take Nike as the case. Asian Business Research, 4(3), 86-93.

Nike. (2017). Know the chain: Forced labor in the leather supply chain . Web.

Silady, A. (2020). The top 10 banks in America. Smart Asset. Web.

Sneaker Factory. (2017). How are Nike shoes made? Cold cement construction. Web.