Executive Summary

The report analyses the creation of value creation through the function of procurement and supply in Abu Dhabi National Oil Company Limited. An investigation of the company’s supply chain structure reveals the nature of ADCO supply chain management division activities. The company is noted as having a comprehensive supply chain management strategy, which incorporates all aspects under the bottom line model. Opportunities for further value generation through the procurement and supply are identified under the models of Mendelow’s and the five rights. Recommendations are ultimately made in line with stakeholders’ collaboration, company policies, and procedures, and the future sustainability of the organization.

Introduction

Abu Dhabi National Oil Company Limited (ADCO) is one of the 15 subsidiaries of Abu Dhabi National Oil Company (ADNOC). ADNOC has operations in the gas, petrochemical, and oil industry, as well as in the transport and services relating to gas and crude oil. ADCO operations include “exploration, production, development, and export of crude oil and natural gas materials extracted from the onshore concession areas.” The following report explores the various current aspects of procurement and supply chain management in ADCO.

Procurement and Supply Chain Activities in ADCO

The main concern of most oil and gas companies is to find, as well as produce oil. Environmental and locations concerns and their respective trade ways in the recent past have however made the operations of these companies more challenging. Consequently, the need for optimal supply chain and logistics solutions has increased.

Procurement is defined as “the process of acquiring goods, works and services, covering both acquisitions from third parties and from in-house providers.” The involved process cuts across the activities of needs identification, to the end of a contract. Various critical buy or make decisions are made under the umbrella of procurement. Supply chains on the other hand refer to the ‘framework of how raw materials are converted into finished products and the products are finally sent out to the consumers is known as a supply chain.’

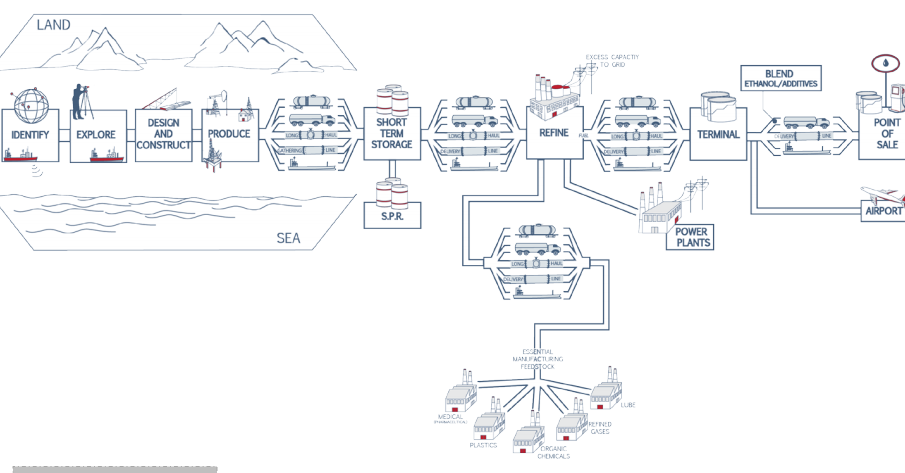

In line with these definitions, supply chain management entails the various operational fields including logistics, procurement, management and information technology. Figure 1 below illustrates a typical model of oil and gas supply chain applied in ADCO:

Apparently, various procurement and supply activities are involved in ADCO supply chain management. The main elements of the company’s supply chain are evident in figure 1 above. The major components include production, pipelines, short-term storage, terminal, refining, shipping, and ports of call and point of sale.

The initial process involves refining crude oil. Stage two involves temporary storage awaiting circulation of the products through the chain of supply.

Shipping channels are the common mode of moving the crude oil to other refineries and foreign markets. The delivery lines also facilitate the transportation of crude oil to refineries. Gas and refined fuel are transported to the terminals which are located closer to the points of sale. They are finally transported to their final points of sale, using trucks, delivery lines, ships, and other forms of transport.

Procurement and Supply Practices in ADCO and Improvement Opportunities

The mission statement of the company reflects the key activities and outcomes expected in relation to procurement and supply chain management. The mission of the company is to explore hydrocarbons, develop and produce the same on behalf of their shareholders. In meeting these needs of the shareholders, the company seeks to operate at a maximum level of efficiency, as well as at the most favorable costs.

The primary elements of ADCO procurement strategy exhibit a design that seeks the lowest possible costs in relation to material bills. At the quotation stage, the purchases team utilizes a web-based and enabled software application in quoting all the franchised components vendors. The purchases team then identifies the most qualified vendors in relation to cost competitiveness and ability to meet the required volume.

ADCO also relies on a top-notch “Health, Safety and Environment (HSE) Electronic Analysis Reporting and Tracking System (HEARTS).” The system provides the capability to execute analysis of incident and environmental data, as well as trend analysis. Despite the tremendous developments in supply chain management, the company still exhibits more room for improvement.

Ways for Improving the Organisation’s Profile through Procurement and Supply Function

Effective supply chain management seeks to reduce costs through easy and fast procurement of materials and production facilities. Later orders from suppliers forces organizations to initiate the production process early, in order to meet their contractual obligations. Consequently, supply chain managers have to come up with optimal production strategies which take into account escalation of costs due to potential delays in the operations schedule.

Mendelow’s matrix proposes that corporate strategies should be formulated from an understanding of the primary stakeholders. (Kaplan). ADCO should utilize Mendelow’s matrix to determine the stakeholders’ expectations, power, and priorities and also resolve their conflicting demands.

Table 1 below illustrates shareholder mapping using Mendelow’s matrix:

On the basis of Mendelow’s matrix, ADCO supply chain management division should be able to categorize stakeholders into various categories. The model divided stakeholders depending on their level of interest in the organization’s strategies, and power to enforce their needs. ADCO should focus on the stakeholders with high power and interest, in facilitating the development and execution of a more effective supply chain management strategy.

ADCO supply chain management division should further include the five rights of the stakeholders in the company’s strategy. The internal and external customers’ priorities in line with the procurement supply should be quantified in terms of price or cost, quality, time, quantity and place.

Table 1 below provides some of the requirements that the ADCO supply chain management division can include in the procurement and supply strategy, to enhance efficiency and effectiveness:

Table 1: Ways of Improving ADCO Procurement and Supply function

Collaboration with Stakeholders and the need for Organisational Policies and Procedures

The stakeholders’ collaboration and need for organizational policies and procedures should be focused on under the triple bottom line concept. The primary concern of most business enterprises is the generation of profits. The three concepts are firmly integrated into the company’s organizational policies.

Apparently, ADCO sustainability report encourages all managers, employees, and other stakeholders to integrate safety, health, and environment in all regular operations. Collaboration with the stakeholders is created by engaging them early in all the procurement processes. The company has a hold on both indirect and direct spending, a factor very critical in the overall performance of the organization.

Conclusion

Transformation of the procurement and supply into the driver for shareholders’ value is a demanding, but achievable task. The benefits from value benefits for an organization are straightforward in the report. It is also apparent that the outcomes are apparent, especially considering that the organization’s returns on investment and capital can ensure the future sustainability of the company. The comprehensive approach to an effective procurement and supply strategy also reveals the benefits accrued to all stakeholders, hence facilitating greater commitment to the success of the business.

Recommendations

ADCO supply chain management has put into effect numerous measures and practices suitable for an organization’s success in the contemporary competitive market. The management should further focus on several key elements essential in addressing the future performance and sustainability of the company. The company’s supply management should devote more efforts towards the development of a more comprehensive procurement strategy, organizational leadership and objectives. Other areas of concern should include the establishment of an optimized organization, innovation and technology, and best practices.

References

Choudhary, A., ‘Analysis and design of supply chain model for a specific organisation’, The Macrotheme Review, vol. 3, no. 8, 2014, pp.71-106.

Fauzi, H., G, Svensson and A, Abdul Rahman, ‘Triple bottom line” as “sustainable corporate performance”: A proposition for the future, Sustainability, vol. 2, no. 1, 2010, pp.1345-1360. (1346).

Fletcher, A., J. Guthrie, P. Steane, G. Roos and S. Pike, ‘Mapping stakeholder perceptions for a third sector organization’, Journal of Intellectual Capital, vol. 4, no. 4, 2003, pp. 505-527. (508).

Golhar, D.Y., and S. Banerjee, ‘An optimal ordering strategy for a third-party managed supply chain’, International Journal of Production Research, vol. 51, no. 10, 2013, pp. 2969–2980.

Lemieux, S., ‘Energy: Understanding our supply chain’, Api. 2015. Web.

Rudzki, R.A., ‘World-class supply practices boost shareholder value’, Financial Executive, vol. 22, no. 23, 2006, pp. 56-58.

Bibliography

Atkinson, A., J. Waterhouse and R. Wells, ‘A stakeholder approach to strategic performance measurement,’ Sloan Management Review, vol. 38, no.1, 1997, pp. 25–37.

Barnett, M, ‘Stakeholder influence capacity and the variability of financial returns to corporate social responsibility’, Academic Management Review, vol. 32, no. 2, 2007, pp.794–816.

Choudhary, A., ‘Analysis and design of supply chain model for a specific organisation’, The Macrotheme Review, vol. 3, no. 8, 2014, pp.71-106.

Colbert, B., and E. Kurucz, ‘Three conceptions of triple bottom line business sustainability and the role for HRM’, Human Resource Planning, vol.30. no.2, 2007, pp. 21–29.

Fauzi, H., G, Svensson and A, Abdul Rahman, ‘Triple bottom line as sustainable corporate performance: A proposition for the future’, Sustainability, vol. 2, no. 1, 2010, pp.1345-1360. (1346).

Fletcher, A., J. Guthrie, P. Steane, G. Roos and S. Pike, ‘Mapping stakeholder perceptions for a third sector organization’, Journal of Intellectual Capital, vol. 4, no. 4, 2003, pp. 505-527. (508).

Frederick, W., J. Post and K. Davis. Business and Society: Corporate Strategy, Public Policy and Ethics, McGraw-Hill International Edition, Singapore, 1992.

Golhar, D.Y., and S. Banerjee, ‘An optimal ordering strategy for a third-party managed supply chain’, International Journal of Production Research, vol. 51, no. 10, 2013, pp. 2969–2980.

Lemieux, S., ‘Energy: Understanding our supply chain’, Api.

Rudzki, R.A., ‘World-class supply practices boost shareholder value’, Financial Executive, vol. 22, no. 23, 2006, pp. 56-58.