Abstract

Lessons from the history of accidents in the construction industry have shown the industry as one that has experienced one of the highest rates of accidents ranging from minor injuries to severe injuries and other forms of severe and mild injuries. Research into the cause of accidents in the construction industry in Saudi Arabia has shown a significant number of injuries with a strong correlation to the failure to apply laws and procedures that guide industry workers against the occurrence of accidents while executing their duties. In addition to that, research has established that many of the workers in the construction industry in Saudi Arabia are either not informed about the procedures and laws that the employee is required to follow at the workplace to guard the worker against the risk of getting hurt in the course of duty. On the other hand, further research has established that negligence on the side of the worker contributes to the cause of accidents that workers incur while at work. The need to enforce safety laws at the government level and the construction industry to guard the worker against the common occurrence of accidents is one of the strongest mitigating measures towards minimizing the rate of accidents in the construction industry in Saudi Arabia.

Introduction

The health and safety of the worker in the Saudi Arabian construction industry is of paramount importance as the construction field proves one of the most hazardous places to work in the world. In Saudi Arabia, no government agency is in place to regulate the safety and health of the worker in the construction industry as is the case in many other parts of the world. Previously many contractors had not realized the value of formulating policies and regulations as standards to regulate the safety of the worker. On the other hand, contractors have not equally endeavored to establish the root cause of an accident in the construction industry. Thus, both knowledge gaps had significantly contributed to the number of accidents in the industry with the toll becoming a financial and human resource burden to the contractors and other stakeholders in the Saudi Arabian construction industry. According to studies by different authors, the knowledge gap in the worker in relation to the safety and health laws and more particularly the failure of the contractor to inform the worker prior to the has had another significant contribution to the industry. On the other hand, safety requirements at the construction site and during the construction work were among the contributing factors to the rising number of accidents in the construction industry.

Many researchers have shown that workers are more susceptible to accidents while at the construction site due to the failure to observe safety regulations outlined in safety manuals. Other workers might be ignorant of such manuals and safety and health laws governing their workplace tasks. Among the cases of accidents specifically identified as the failure to b informed about workplace safety rules and regulations include workers or a worker falling from high-rise construction sites due to the failure to wear the required necessary gear. That might be in part due to the negligence of the worker to wear belts and other protective gear or the failure of the management of the contracted firm to provide the necessary gear.

Studies by Andreoni (1986) have shown the estimated number of fatal accidents in the construction industry at 1096 with a 15.7 % fatality rate. That translates to 11 948 fatalities of the seven million working population in Saudi Arabia. Comparative figures with other countries including Qatar indicate a fatality rate of 11 545 accidents translating to 15.1 % of the total population engaged in construction work. Other statistics in the construction industry indicate Oman has a fatality rate of 18.9% translating to 14 393 accidents in the construction industry. A typical characteristic of the spread in the number of fatalities has shown a strong correlation with industry information or knowledge on the side of the worker. In addition to that, the lack of proper training on the part of the worker in the construction industry is another additional source of fatalities in the construction industry. On the other hand, little has been done to apply safety laws and regulations and a stark failure to inform the worker on the laws related to their safety in the construction industry.

Many studies related to the occurrence of accidents in the construction industry have taken a multi-pronged approach. Theoretical propositions on the cause of accidents have shown a strong correlation between the rates at which accidents occur with management involvement, the behavioral attitude of the worker, unsafe acts of the worker, unsafe working conditions, failure to observe the law regarding the safety of the worker, and unsafe working environment. These theoretical propositions have agreed with practical observations in the construction industry in Saudi Arabia. Thus, reinforcing the need for the worker to be well informed about the need for occupational health and safety laws and to apply the laws at the workplace.

Background of the Research

Osama and Assaf (1998) have both shown that diversity in the methods and ways of implementing construction projects has become a major concern as this prompt’s compliance with the regulations and safety measures required for any type of work to be performed. In their study, Osama and Assaf (1998) focused on the safety requirements and the precautions necessary to ensure the safety of workers and individuals, property, services, and public utilities. Such safety measures ensure that accidents at work resulting from faulty working tools and equipment, poor procedures, and human errors are promptly avoided. Liu & Ling (2005) asserted that when safety measures are put in place and fully adhered to, these preventive actions will effectively contribute to helping the workers to accomplish their tasks properly and safely, without injuries to personnel, damages to property and public facilities, and wastage of public wealth. In view of this, the individuals in charge such as engineers, technicians, and administrators are compelled to exert more effort in ensuring that the workers comply with the regulations for quality output (Koehn, Kothari & Pan, 1995).

On the other hand, it is important to establish an overview of the importance of the construction industry in Saudi Arabia. Al-Jarallah (1983) has shown that between 1975 and 1985, the government of Saudi Arabia invested between 49% and 49.8% of the government expenditure in the construction industry. It has been estimated that the construction industry in Saudi Arabia employs over 15% of the entire labor force in the country.

Statement of the Problem

Insufficient information about the causes of accidents at the construction sites and the observed poor implementation of safety standards in the construction industry in the Kingdom of Saudi Arabia has led to an increase in the rate of accidents at these sites. For instance, KSA registered 102,259 accident cases and 493 deaths associated with the accidents, as presented by (Koehn, Kothari & Pan, 1995).

Purpose of the Study

The purpose of the study is to establish the common cause of accidents at construction sites in the Saudi Arabian construction industry, the need for the government, the contractor, and industry stakeholders to formulate policies to safeguard the worker from the common cause of accidents enforceable by government regulations. According to studies by Burke (2010), Saudi Arabia has the highest growth rate in the construction industry, showing a 38% growth rate. In addition to that, of the total number of employees in the construction industry, 15% of the workforce has experienced accidents while at work. Thus, translating to a large number of people being hurt during the construction work.

Research Questions

- What are the main causes of workers accidents in construction projects in Saudi Arabia: “the vulnerability of the safety laws or the failure to implement such laws?”

- How do the worker, the contractor, and the government apply safety laws, procedures, and policies to protect the worker from the causes of accidents n the construction industry?

- What requirements and safety standards does the worker need to observe at the working site to stay safe and healthy during the construction period?

- Which research methods informed the study?

Importance of the Study

The construction industry in many parts of the world and in particular Saudi Arabia has recently registered significant growth attracting a large number of local and foreign contractors. However, the construction industry suffers from the problem of high accidents rates particularly affecting the workers. These accidents range from minor injuries to fatal injuries which either result in deaths or permanent disabilities impairing the worker’s capacity to get involved in gainful living. Further still, the trend seems not to abate but remains consistently high as the construction industry in Saudi Arabia continues to grow. Typically, research has shown that the number of accidents has been partly due to the failure of the government to enforce the compliance of safety and health laws on the part of the stakeholders. On the other hand, the contractor, the designer, and the worker take a share of the blame for the failure to adhere to the safety and health laws and procedures when executing construction work tasks. Thus, the need to study and establish the actual causes of accidents in the Saudi Arabian construction industry and in particular at the construction sites and determine preventive methods to help curb the rise of accidents and ensure the safety of the worker from such accidents. The study endeavors to establish the law, the designs, the worker, and the contractors in their different capacities in contributing to the occurrence of accidents and the best approaches of mitigating the accidents.

It is important for the worker at the construction site to be well informed about the laws related to one’s health and safety in the working environment, to be aware of situations that persist ate the workplace, to be aware of safety procedures and policies in the workplace, and the best approach to work. In addition to that, it is important for the worker, the designer of a construction project, and the contractor to each identify various points at which to play the role of early detection and reduction or mitigation for the risk of an accident during the construction work. Typically, the designer has to design for safety, the management and the contractor have to work in tandem and formulate and enforce safety policies and regulations, and training programs to keep the worker safe from accidents.

Scope and goal of the Study

The goal of this research project is to improve the safety conditions in the construction sites in KSA and reinforce the workers’ occupational health and safety in KSA construction sites.

Definition of Terms

- Risk———The likelihood of an unanticipated event occurring that adversely affects project progress.

- Accident ——An undesirable occurrence that adversely affects project progress or the ability of one to carry out activities.

- Law——–A rule or expected conduct from the authority.

- Heath———A state where an individual has a sound body and mind enabling the execution of building tasks.

Literature Review

Research into the construction industry particularly in Saudi Arabia shows the need for regulatory constraints to protect employees working in the construction industry against commonly occurring accidents (Aksorn & Hadikusumo, 2008). Accidents, according to statistical studies taken in many parts of the world and in particular Saudi Arabia have shown the need to impose occupational safety laws to protect workers in construction (Agarwal, & Everett, 1997).

History

According to (National Institute of Occupational Safety and Health, 2006), the history of occupational health and safety laws had a beginning with the German physician in 1473. At that time, accidents related to the construction industry were frequent and were markedly on the rise. In addition to that, the construction industry was losing several workers and some of them, the highly skilled. That reinforced the need to formulate policies, safety laws, and methods to address the problem associated with rising accidents in the construction industry. On the other hand, studies by the National Institute of Occupational Safety and Health (2006) have taken the history further by affirming that during the industrial revolution, many countries had formulated work safety laws that were imposed on construction firms particularly to protect the workers at all levels of project implantation. That has also been the case in the construction industry in Saudi Arabia.

Further, to reinforce the need for occupational health laws, many countries such as Britain formulated industrial laws related to the construction industry, back in the 18th century. These laws were enforceable using different industry tools such as insurance companies making industrial safety a priority.

According to (National Institute of Occupational Safety and Health, 2006), there were no significant variations in the way health laws were enforced in the construction industry until new methods of enforcing occupational health laws were developed by Heinrich in 1930. At that time, not many theories had been developed to address issues related to construction industry accidents. However, Heinrich had developed a theory known as the Domino Theory to address industry related. The theoretical framework was however narrow in perspective on the cause of accidents in the construction industry.

On the other hand, many other countries had started to realize the need to minimize the rate at which accidents were occurring in the construction industry. One such was the United States of America. In 1976, the United States was leading in enacting the law on occupational health to protect employees and other construction workers against the risk of incurring injuries that might lead to fatal deaths. On such law included the occupational health law in the USA. Ashford (1976) and the National Institute of Occupational Safety and Health (2006) have however noted a deep rift between the industry laws at the time and later developments in the construction industry.

Introduction

Occupational safety laws are a fundamental asset in the construction industry particular to protect workers and minimize or reduce the rate at which accidents occur in the industry. Many countries have formulated their laws and regulations to address the issue of safety, particularly for the construction worker. That is the case with the construction industry in Saudi Arabia. The need to apply the laws to protect the worker against the high rate of accidents in the construction industry is demonstrated by the magnitude of accidents that occur in the construction industry. To address and establish the rationale for the need for construction safety laws, it is important to examine the most important causes of accidents in the construction industry from the perspective of the application of the safety laws from the perspective of the worker, the contractor, safety laws, and from the design perspectives (Aksorn & Hadikusumo, 2008).

The Worker

According to Aksorn and Hadikusumo (2008), the safety of the worker at the construction site particularly in the Saudi Arabian construction industry is of paramount importance that stakeholders in the industry have to enforce, as safety is critical in contributing to the productivity of the employee. That fact receives further reinforcement by the fact that the construction industry constitutes several activities that always expose the worker to the risk of an accident, reducing the productivity of that employee and in other cases disabling the employee completely (Baig, 2001). Thus, the government and the employer who in this case is the construction firm are under legal obligations to ensure the safety of the construction worker. Thus, it is an important requirement that the safety of the worker at the construction site is managed accordingly. In addition to that, there is a need for safety laws to protect the worker at different levels at the construction site (Baig, 2001).

The health of the worker is of paramount importance in the construction industry as productivity has a strong correlation with the health of the worker. An unhealthy worker is likely to spend more time tending to health than being productive at the workplace. In addition to that, an unhealthy worker has not had the strength to fulfill workplace objectives, reducing the output and increasing the likelihood of increasing the chances of getting more injuries.

Workers in the construction industry in Saudi Arabia are the most vulnerable in the industry. That is particularly because workers incur injuries that result to death, amputations, or lifelong disabilities. Research into the common causes of accidents in the Saudi Arabian industry correlates accidents to the lack of workplace laws and laws that govern the kind of compensation received by the worker in the event of an accident (Bu-Khamsin, 1999).

According to the Saudi Arabian labor laws, article 139 stipulates that a worker shall receive appropriate compensation in the event of sustaining any type of injury be-it inflicted intentionally or unintentionally (Bu-Khamsin, 1999). The article further details conditions under which the worker is susceptible to compensation in the event of an injury. However, a knowledge gap appears herein that the law does not stipulate minimum safety requirements that a worker has to comply with as a measure against the possibility of incurring an injury. In addition to that, the law does not stipulate the obligations and legal requirements binding the worker to his or her safety. Thus, the need to study in detail common causes of accidents and the need to apply occupational health and safety (OHS) laws in the construction industry.

Common causes of accidents

Research by Bu-Khamsin (1999) has shown that at the operational level, several theories formulated to examine the common cause of accidents in the construction industry have come with different explanations. However, the importance of the construction industry in Saudi Arabia calls both for the need to borrow and identify the fact that the Saudi Arabian construction industry can borrow from the theoretical propositions on the common causes of accidents by relating the theory to the worker in the construction industry (Bu-Khamsin, 1999).

Abdelhamid and Everett (2000) researched to identify and understand the root causes of accidents in the construction industry in general. In their research, Abdelhamid and Everett (2000) endeavored to identify the type of accident and relate the accident to the direct causes. In addition to that, the researchers wanted to know how the accidents occurred concerning the direct cause of the accident. In their studies, Abdelhamid and Everett (2000) settled at the need to supplement theoretical explanations for the cause of accidents based on human theories. The reach was further reinforced by the fact that by 1996, up to 350,000 workers in the USA had incurred fatal injuries in the construction industry, some resulting in death and others in permanent disabilities. On that note, therefore, Abdelhamid and Everett (2000) related that among the common causes of accidents worth investigation, in theory, included:

- The need to identify safe and unsafe conditions before and after the commencement of an activity with the potential to cause an injury at the work place and the need for a legal requirement to conform to work safety rules and laws.

- Ignoring findings that the current working condition was unsafe and deciding to execute work after realizing that the situation is unsafe.

- A worker decides to expose oneself to an unsafe working environment by continuing to work in that environment with the full knowledge about the dangers one is exposed to.

Abdelhamid and Everett (2000) proposed that the workers were exposed to unsafe working conditions due to their unsafe acts, management involvement, the nature of the construction site, and non-human related factors. A critical analysis of the Saudi Arabian construction industry shows the above factors to be inherently descriptive of the working conditions in the industry (Bu-Khamsin, 1999).

Human error theories

From the theoretical perspective, human theories strongly hold that the common causes of accidents are due to the direct cause of human beings. According to Abdelhamid and Everett (2000), the theory on human beings as is the case with Saudi Arabian construction is based on the tendency of the human being to make errors that is an unsafe characteristic in the human being. Workers in the Saudi Arabian construction industry are multicultural as they come from different nationalities and backgrounds. Many of the workers lack the basic skills to enable the completion of construction tasks safely and comprehensibly. Thus, according to the theory, the tendency to make mistakes is characteristically inherent in the worker.

On the other hand, Chua and Goh (2004) have developed a consensus that the theory holds that besides the inherent characteristics in the human factor, the work design is another contributing factor to the common cause of accidents in the Saudi Arabian construction industry. That is typical because some of the work place tasks and work design do not account for the limitation in the human being, and eventually end up having serious harmful effects on the human being (Everett, 1999). That reinforces the need for the construction industry in Saudi Arabia to factor laws and regulations that control the work place design to protect the employee against the dangers of working in an environment beyond human control (Everett, 1999).

According to Abdelhamid and Everett (2000), work place accidents particularly those that affect the safety and health of the worker in the Saudi Arabian construction industry are worth modelling, based on the behavioural model. While the law may protect an employee or worker against the occurrence of an accident by enforcing minimum safety regulations, a theoretical proposition on the behavioural model shows that human beings have intrinsic attributes that make them accident-prone. The theory gets much support the fact that when considering industry wide statistics on the number of accidents that occur in a specific construction period, the results indicate a small percentage of workers incur injuries of different kinds, while the majority of workers remain safe. Typically, that implies that the worker’s behavioural characteristics influence one’s exposure to accidents and the likelihood of incurring an accident. In support of that proposition, Klumb (1995) agree with Abdelhamid and Everett (2000) that human contribution is a significant factor in influencing the number of errors experienced in the Saudi Arabian construction industry. In Saudi Arabia, one is bound to argue that there could not be a need for a law to protect a worker against not using building tools effectively. However, other authors contest this theory by arguing that accidents are typically a chain of events with human error playing a central role in a chain of events. In this model, human error is seen because of overload, incorrect response, and untimely response to a situation that leads to an accident and incorrect handling of a task or deliberately leading exposing oneself to an accident situation (Fabiano, Curr & Pastorino, 2004).

In practice, the theoretical framework suggests that both situations demand the application of a measure to protect the employee or the worker from working under excessive load. Working under excessive loads might be a direct influence by the management, one’s desire to complete a piece of work before the stipulated time, one’s willingness to subject self to overwork, and other related human factors (Saudi Aramco, 1995). An example includes a situation where management in the construction projects industry remains behind schedule and has a likelihood of experiencing cost overruns. Several studies show that many employees working in the Saudi Arabian construction industry experience compelling situations where workers are subjected to work overloads and the likelihood of incurring injuries due to overloads such as working long beyond normal working hours, carrying extra weights, and other related overloads. That has further reinforced the need to enforce safety laws in the construction industry in Saudi Arabia (Fabiano, Curr & Pastorino, 2004).

A critical analysis of the working environment in the construction industry in Saudi Arabia shows one of the frequent causes of accidents in the construction industry to be unsafe working conditions. In addition to that, the lack of legal enforcement and laws to protect worker against working in unsafe working conditions contribute significantly to the rise in the number of accidents in the industry. Petersen (1982), Bird (1974), and Heinrich (1959) concur those unsafe working conditions, especially as applied in the Saudi Arabian construction industry, has made significant contributions to the number of accidents that occur in the industry. In theory, it is common practice to discuss and point out unsafe conditions as one source and the main cause of accidents in the construction industry. However, in theory, and practice, common causes of accident in the Saudi Arabian cost ruction industry is mainly due to working in open-sided floors, defective and improperly used floors, poorly constructed scaffolds, poorly finished floors and rods, nails and protruding nails, and overloaded tools and equipment. Other materials contributing to unsafe working conditions include explosive materials and flying materials. Thus, the safety of the worker is always under constant jeopardy in the Saudi Arabian construction industry (Fabiano, Curr & Pastorino, 2004).

However, unsafe conditions subjecting the worker and making the working environment prone to accidents is susceptible to becoming safe through legislations and laws that demand and impose minimum safety requirements to adhere to, to address the working conditions of the worker. In every aspect of preparing for the commencement of work, there is a need for a minimum legal requirement to adhere to in ensuring the enforcement of minimum safety procedures in the working environment during the working period. However, research into the practical environment indicates that the rigorous requirements of the law sometimes subject the construction firm to additional costs with negating implications on the overall productivity and rate of accidents in the construction industry in Saudi Arabia.

Research by Fabiano, Curr and Pastorino (2004) has shown one of the problems contributing to accidents at the work place was due to management failure to provide employees with appropriate protective gear making the working environment all tool dangerous. In addition to that, management failure to enforce regular maintenance on construction equipment, failure to inform or provide adequate information on the conditions of the working environment such as situations of working on slippery floors, poor housekeeping methods, and several other work place safety Violations. On the other hand, lacking safety regulations and laws in the above situation particularly at management level is a comprehensive reason for the occurrence of such accidents. In addition to that, one can conclude that work place safety laws and regulations at management level, project level, and operational levels are likely to minimize the rate of occurrence of accidents. A typical example is a situation where the management does not provide explicit information on the slippery conditions of a working floor, the danger associated with working in a given environment, and poor housekeeping. On the other hand, if management finds itself under the obligations of legal requirements, then the possibility of minimizing the rate of occurrence of accidents at construction sites related to the above working environment. In addition to that, there is the possibility that a worker might be inexperienced, new at the work place, or not have the necessary skills to handle equipment, not conversant with the work place, and might be unable to recognize the need to apply safety procedures at the work place.

A typical example is demonstrated in a situation where workers in the Saudi Arabian construction have shown negligence in observing safety laws and regulations by removing protective gear from machinery and working in situations that demand the use of protective gear. Typically, if law enforcement is observed on the safety of the worker, the possibility of a worker being injured, or incurring an accident during the working hours can be minimized. On the other hand, the need to enforce the law during and at the construction site is further reinforced by the fact that some workers report at their destinations or working site while under the influence of intoxicating substances. Thus, a drunken worker is highly susceptible to injuries at the work place. That might be partly due to the failure of the worker to use cognitive skills appropriately while at the work place when handling construction equipment (Abu, 2007).

According to observations by Ferrel (1977), management plays a significant role in facilitating the rate at which accidents occur in the constructuo9n industry by instructing the human work force to perform tasks far beyond their capacity. A case in point, in the Saudi Arabian construction industry, many workers at the operational level usually find themselves under the obligation to obey direct instructions from the top-level management to perform tasks that are beyond their capabilities. The consequences are that these employees are hurt or injured while on duty.

A critical evaluation of the management and worker relationship, based on the above argument demonstrates the need for an arbiter and a legal obligation to bind both the management and the worker. The legal argument draws on the fact that the management, the contractors, or the worker cannot abridge a law on safety as the legal requirement is always for the best interest of the worker. That explicitly implies that either party engaged in a construction activity must observe the law on safety i.e. the management and the worker. Instead of that, the management cannot instruct an employee to perform a task requiring more work force or beyond the capability of the human being.

According to Ferrel (1977), other areas that need observations and the enforcement of the law to uphold the safety of the worker at the construction site include the terrain of the construction site. In addition to that, there should be a law to govern the safety of workers when operating in an environment with concealed ditches, into which a worker might fall into causing an unexpected injury, scattered sharp metallic pieces, high-rise buildings where the worker might be working and the susceptibility of the worker experiencing a fall.

It is well worth examining the cause of accidents in other regions of the world to borrow and uniform the construction industry in Saudi Arabia on the issue of the rate at which eternal and internal factors influence the rate of occurrence of accidents in the industry.

The Employer

One of the elements to consider in construction industry particularly concerning the safety of the worker is the employer. The employer is one of the critical assets in ensuring the rate of occurrence of accident in a construction site are minimized by the stringent application of safety laws and rules to be observed during the working period. However, many employers in the Saudi Arabian construction industry do not enforce safety standards against established laws, requiring that the employer comply worth specific legal requirements to meet the safety standards in a working environment. Saudi Aramco (1988) has sanguinely shown that management and the employer are always under the obligation to ensure the working environment is safe for the worker and free from accidents. In addition to that, the employer should formulate policies and training programs for the employees working in the construction industry to ensure adequate information on the use of various categories of equipment and careful handling of industry tools (Kartam, 1997).

Further studies by Henry (1986) and co-researchers in the construction industry have shown that the employer in the construction industry should formulate safety plans and regulations to govern and eventually minimize the rate at which accidents occur in the construction industry. On the other hand, a critical evaluation of the construction industry in Saudi Arabia shows that more often than not the management and the employer are under the obligations to pass on information about the safety of the worker at the construction site. In addition to that, there is need to conduct safety training programs which largely include inducting workers and employees on safety requirements at construction sites.

Employers at the construction sites often find the cost of conducting safety programs high with implications on a construction firm’s profits. However, it is worth the argument that the long-term effects on the cost of the worker may override the preventive measures taken to train employees on their safety at the work place. However, due to the lack of legal requirements reinforcing the need for a workplace safety program by contractor firm, the government and other law enforcement agencies need to outline measures to reinforce the observance of the law at the work place, particularly concerning the safety of the employee.

On the other hand, various factors for consideration at the work place compel the employer for the need to educate the employee about various safety measures and enforce the observance of the safety laws at various levels of project implementation. The safety measures for inclusion include:

- Head protection

- Foot protection

- Eye Protection

- Hand and body protection

- Respiration protection

- Fall protection

- Weight lifting techniques

- Welding and cutting

- Use of petroleum and other liquid gases

Head Protection

According to Fung, Ivan, Tam, Tung, Karen, and Man (2005), head protection is one area of fundamental importance for the worker since injuries caused on the head are mostly fatal. These kinds of injuries or accidents sometimes lead to deaths or lifelong incapacities. On the other hand, according to Fung, et al, (2005), head protection is important and the worker needs to be informed or made aware of the head protective gear to use during the working period. That is typically since the likely cause of head accidents and injuries are falling objects, sharp and protruding objects, and other overhead loads that subject the head to the threat of being injured (Fung, et al, 2005).

Studies by Hassan, Basha and Hanafi (2007) on the potential for a falling object to cause a serious injury on the head has been demonstrated on the impact of a falling object, as small as a bolt, falling from a height of just 20 cm under the accelerating force of gravity. Several instances have shown that falls have the potential to cause death or serious injuries on an unprotected head (Hassan, Basha and Hanafi, 2007).

In Saudi Arabia, injuries due to falling objects particularly on the head have registered a significant number. On the other hand, it hardly has been demonstrated that employees or workers at such construction sites adhere to the safety laws and regulations demanding for the observations of putting on protective gear. In addition to that, many workers do not observe the safety requirements, particularly when working in areas known as “hard-hat-areas” by wearing protective gear all the working time (Hatush & Skitmore, 1997).

Thus, the need to communicate in explicitly terms on the need for workers, particularly when working in areas designated as “hard-hat-areas” to observe safety laws and regulations. In all these, there is a clear need to enforce laws and regulations on the worker for the sake of safety and protection (Jannadi & Bu-Khamsin, 2001).

Foot Protection

Another part of a work that needs stringent observations of the safety laws is the foot. According to observations made by Sawacha, Naoum and Fong (1999) on employees particularly in the construction industry is the nature of employees who adopt an attitude, which does not allow them to put on protective gear and particularly to protect the foot against common accidents. These accidents include those sustained due to falling objects and penetrations by sharp objects such as nails (Chua & Goh, 2004).

However, there is a need to communicate to the worker about wearing protective footwear to cover the feet against penetrating or falling objects (Shash & Abdul-Hadi, 1993). In addition to that, the communication and enforcement of safety laws requiring worker to wear protective gear while at work is important (Everett, 1999).

On the other hand, safety laws and requirements dictate that the worker be informed to identify the most appropriate gear for protective footwear. In addition to that, there is the need for the law to enforce a standard for the footwear to conform to depending on the working environment. Thus, the need to identify different designs of footwear in the construction industry suited to particular and specific construction situations (Kartam, Flood & Koushki, 2000; Tam, Zing, & Deng, 2004).

On the other hand, there should be an enforcement of the law requiring the use of footwear and helmets at any construction site during the construction period.

Eye Protection

The eye is an important part of the body and requires protection to be always enforced in the construction period. One of the common causes of accidents has been identified to be either poor eyesight or damage to the eye during the working period. Common causes of eye damage in the construction industry in Saudi Arabia are largely due to flying particles or materials (Teo, Ling & Chong 2005). In addition, objects that fall on the face when a worker attempts to look upwards at falling objects, radiation, cutting of materials and rods, welding metals and other related works, and grinding of materials or using grinders to cut metals (Kartam, Flood & Koushki, 2000).

Hand and Body Protection

Other causes of accidents identified at the level of the worker and the need for the employee to formulate methods of protection include hand ad body protection (Low, 1989).

Respiration Protection

Respiratory protection demands that laws and safety rules be enforced to protect the worker against the effects of the chemicals, dust particles, and other related inhalations that may eventually lead to long term breathing problems (Low, 1990). It has been established in the construction industry particularly in Saudi Arabia that workers are less often protected from inhaling dangerous fumes and other chemicals that result from activities occurring in the construction industry (Low, 1990). These wastes are because of activities such as crushing and handling of rocks, blasting particularly sandblasting activities, paint-spraying activities, and flying particles due to welding activities (Low, 1990). These have been identified to be some of the common causes of accidents in the industry in Saudi Arabia.

Fall Protection

Many regions of the world particularly where construction work occurs have identified falls to be among the leading causes of accidents for the worker. In particular, Saudi Arabia has registered a significant number of deaths and injuries due to falls (Low, 1990).

In the construction industry in Saudi Arabia, accident due to falls is a result of employees or workers slipping while at work, failing to observe safety precautions while working in high-rise buildings or at times and more particularly, the failure by the worker to harness safety in high-rise buildings (Low, 1990). On the other hand, the lack of information on the need to observe laws relating to safety while working on high-rise buildings is another significant factor contributing to accidents in the construction industry. One of the safety measures that should be enforced by the law includes wearing safety belts or in other cases wearing safety nets (Low & Goh, 1992).

Weightlifting Techniques

Sometimes falls and accidents might be due to poor weightlifting techniques. It is a common practice in the construction industry to execute daily activities by lifting building materials at regular intervals. It is important therefore to equip the worker with adequate knowledge and requirements on the need to observe scaffold regulations in weightlifting (Low & Goh, 1992).

On the other hand, there should be safety laws relating to appropriate methods of securing loads before carrying them to avoid instances of injuries due to improperly secured falling weights (Low & Goh, 1993). In addition to that, it is important to observe and be informed about regulations and standards to observe when carrying weights up a ladder, procedures to safely secure weights while ascending a ladder, and the weight limit to be carried at one go when ascending a ladder. It is perhaps of utmost importance for the worker to be informed before using a ladder about the importance of securing a ladder before use (Low & Goh, 1993).

Industry estimates indicate that a greater percentage of ladder falls are due to slipping, insecure, and slippery ground. In addition to that, a worker might fail to carry a ladder according to safety regulations simply because of the failure to be informed about the safety of carrying such a tool (Low & Goh, 1993).

Welding and Cutting

Welding is another element considered as one of the causes of accidents in the industry. Welding, according to industry information has the likelihood of causing accidents through electric shocks, flying particles, disconnection of wires, naked electric wires, dragging of flexible cables over sharp edges, and wrong connections of terminals (Mohamed, 2002).

Use of petroleum and other liquid gases

Petroleum and other liquid gases form an important part of the construction industry. That is particularly due to gas welding and other activities that require the support and use of petroleum and related substances (Mohamed, 2002).

Design for Safety

Mattila, Hyttinen, and Rantanen (1994) identified design safety to be a critical component in the construction industry. According to industry studies, successful implementation of construction projects and safe working environments start with the design. It is argued that design is critically influenced and inherently critical in the construction process, operations process particularly at the operations level, and other necessary legal requirements for health and safety in the construction environment (Mattila, Hyttinen, & Rantanen, 1994).

On the other hand, safety hazards at times must originate with the design and the need to eliminate the possibility of such hazards at the commencement of the design. According to industry research, designers are best placed to design reduce risks specific to the construction industry.

According to research conducted in the European Union, most of the injuries that workers incur at the construction site are due to poor design decisions, during the preconstruction phase, inappropriate design specifications and other technical requirements, and other related design problems. In addition to that, design has significant implications since errors and defects introduced to a product may result from imposed constraints, and the response of the designer to design specifications that lead to accidents (Ng, Cheng & Skitmore, 2005).

According to Ng, Cheng and Skitmore (2005), one of the principles of design that factors early response to accidents is to apply appropriate design processes at the planning and management levels, the control and operations level, and site conditions before the commencement of the construction process. On the other hand, the designer and the contractor need to consider design for safety factors including:

- Make appropriate designs to avoid the possibility of any foreseeable risks that have the possibility of subjecting the worker and other third parties to accidents.

- Ensure workers are fully informed of legal and safety procedures and rules during the construction work.

- Ensure that workers are fully informed about the safety and health of the workers and the construction materials sued in the construction process.

The safety Law

It is important to consider the issue of safety and health in relation to legal requirements binding the contractor, the worker, the government and other stakeholders in the construction industry. Legal and policy requirements bind stakeholders in the construction industry particularly with regulatory issues of effective planning, work place organization, and continuous measures to ensure effective control and review of measures to ensure safe effective implementation in the construction industry. In Saudi Arabia, the government has formulated safety laws that require stringent adherence to work equipment regulations and related industry requirements.

It is important to consider legal requirements to enforce safety at all levels of development including operations, examination and tests, installation of equipment, and lifting and appliance gear.

Methodology

A study on the occupational health problems affecting employees working in the Saudi Arabian construction industry was conceived with the objective of examining the reason for applying safety laws in the construction industry. The study into the occupational health of employees working in the construction industry in Saudi Arabia will depend on qualitative and quantitative data. Qualitative studies are highly subjective in nature while quantitative research is highly objective in nature.

Occupational health is one of the fundamental aspects in the construction industry particularly for employees working in the construction industry in Saudi Arabia. Employees working in the construction industry need to be protected from accidents using different methods. One of the methods applied included laws designed to projects the employee against situations and events that lead to such accidents. On the other hand, it is clear that governments throughout the world have laws that apply at the management level, project level, and operational levels to protect workers from fatal or minor injuries. In addition to that, the laws are designed to offer adequate compensation for the employee who might sustain injuries at the work place, particularly when working for a construction firm. However, the rationale to integrate laws at different levels of construction projects to protect the employees from the cause of frequently occurring accidents in the construction industry requires an in-depth inquiry (Ng, Cheng & Skitmore, 2005).

Research Design

A social research design is a logical structure used to guide the study into a logical conclusion about the need to apply safety laws in the construction industry and the cause of the number of accidents experienced in the construction industry in Saudi Arabia. That is in particular to the reason that applying the safety laws or not applying the laws is the major cause that leads to the occurrence of accidents in the construction industry. In addition to that, the research will crystallize how different variables contribute to the factors that influence the cause of accidents in the construction industry in Saudi Arabia. According to Fellows and Liu (2008), qualitative and quantitative research techniques are fundamental tools to enable the research subjectively and objectively identify the causes of accidents in the construction industry in Saudi Arabia the frequency with which these factors occur and how they affect the productivity of employees working in the construction industry in Saudi Arabia.

On the other hand, the research design will be exploratory, as it will be used to supplement knowledge and qualitative data gained from a literature review on the frequent cause of accident in the construction industry due to the failure to apply safety laws. On the other hand, the descriptive design will provide knowledge about the situations and events that lead to the frequency of accidents in the construction industry in Saudi Arabia. In addition to that, exploratory research will establish the relationship between the events, culminating to the cause and effects researched. On the other hand, given the nature of work in the construction industry, assessments of the research participants of the study will be on an individual basis, thus leading to a hybrid of approach in this study (Olsen & St.George, 2004).

Population and Population Frame

According to Eze et al. (2005), the population of interest in the study is employees particularly at the operational level who are highly susceptible and accident prone in the Saudi Arabian construction industry. Thus, the population of interest refers to the number of respondents to whom research tools are used to capture data that specifically answers the research question on the common causes of accident sin the construction industry.

On the other hand, the research population will be representative in answering the type of accidents that occur in the construction industry, the reasons why these accidents occur, and the implications of the occurrence of these accidents to the construction industry in Saudi Arabia.

The population will therefore consist of the number of accidents ranging from fatal injuries to minor injuries incurred by construction workers at the construction site. These might include injuries due to falls, accidents due to excavations, electrocution due to poor handling and use of electrical equipment, injuries sustained due to being hit by falling objects and injuries sustained sue to the health occupational health hazards in the construction industry.

Sampling Technique

Sampling techniques come in various categories to address specific research questions. According to the nature of the research in question, a stratified sampling technique will apply in the study to break the participants into specific research groups (Biggam, 2008). Stratification of the population will adequately represent the population under investigation. Typically, the sample size will represent employees who have incurred injuries due to a wide range of causes in the construction industry in Saudi Arabia. However, to ensure the research sample fits well into the environment under investigations, each of the samples have to conform to a specific size acceptable in the study. On the other hand, it is important to establish the variables that link research variables in the industry in relation to the population affected by accidents in the industry.

According to Uzoagulu (1998), the minimum acceptable sample size acceptable in the study generalizes to the following mathematical expression:

n=N/ ((1+N (e) 2)

In the above mathematical expression, each of the symbols represents specific variables. These include:

The sample size-n

A finite population in the study-N

Unity-I

The significance level-e

On the other hand, it is important to establish the sample size and sampling frame to allow for the use of a probabilistic model and sampling technique in the study. On the other hand, a stratified sampling procedure requires that the researcher divide the population into homogeneous groups and sub-groups from the population. According to Trochim (2006), the sample is divided into sub-groups from which smaller samples that are representative of the whole population are selected. On the other hand, it is important to reduce biasness during the sampling process by dividing the population into strata, which makes the participating population unique on its own (Eze et al., 2005).

On the other hand, each of the participating samples are assigned numerical values which are randomly generated numbers using a computer in the study. Then sample selections are then taken from the randomly assigned values. It is also important o make informed decisions on data selection from the study.

Data Selection

The nature of data used in the study to provide empirical evidence falls into qualitative and quantitative data. According to Naoum (2007), qualitative data is highly subjective and draws heavily on the meaning derived from the data and the experience due to subjectivity of the study. In theory and practice, subjective data is both exploratory and attitudinal. Thus, to explain the cause of accidents in the construction industry in Saudi Arabia, subjective data will provide empirical evidence in the study. On the other hand, the factors that influence the cause of accidents in the construction industry at different levels of project implementation will further inform the study. Thus, subjective evaluation of respondents will provide evidence about the common cause of accidents in the construction industry in Saudi Arabia. Thus, qualitative data will provide a basis for evaluating the cause of accidents based on the perceptions of the participants in the construction industry. In addition to that, as mentioned elsewhere in this study, a literature review by different authors on the common causes of accidents will contribute significantly to the study.

On the other hand, quantitative data is objective and lacks the abstractness that defines qualitative data. In addition to that, numerical values attached to quantitative data are concrete and based on hard and concrete evidence. In addition to that, it is evident that quantitative data is highly tangible and relies on the sensations of users in nature (Bouma & Atkinson, 1995). The research objectives directly relate to influencing the outcome of the research.

Given the nature of accidents in the construction industry, operational level employees find a greater exposure and at a high risk of incurring risks related in the industry. In the study, an investigation into the common causes of accidents in the construction industry, exposure of artisans and other industry players to accidents was considered a common source of data as follows:

- Failure by the artisan to identify unsafe conditions when at work

- Failure to by the artisans to identify unsafe conditions when a construction activity begins and the procedures governing the safety of the artisan

- Working while knowing the conditions under which the work is progressing are unsafe.

- Unsafe working conditions set by the workers.

- The failure of top-level management to make the working environment safe for the artisans.

- Non-human related events that lead to accidents.

- Behavioral characteristics of workers in the construction industry.

- Accidents due to falls

- Accidents due to being stuck by machinery

- Accidents due to electrical shocks

- Accidents due to wall openings

- Accidents due to poor use of ladders

- Accidents due to protruding bars.

- Accidents due to collapsing walls.

- Interruptions

- Failure by the management to educate workers on their safety.

- Failure to educate employees on the use of protective gear.

Role of the Researcher

The role of the researcher is to identify appropriate methods for collecting and analysing data, identify appropriate subjects to whom questionnaires are administered and interviewed, evaluate the best mechanism for coding and reporting data, and identify the rate at which the performance measures are to be applied in the construction industry.

Measurements

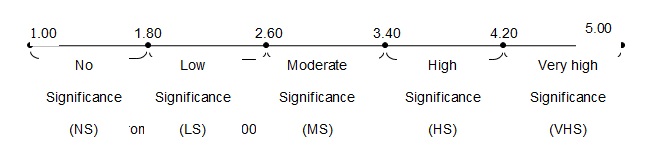

Data analysis will be based on the coding of various success factors on a scale of 1 to 5 as follows:

Entirely dissatisfied-1, Mostly dissatisfied-3, Lie between dissatisfied and satisfied-4, Satisfied-5, fully satisfied-6.

The basis for the research is to identify the reason for the frequent occurrence of accidents in the construction industry in Saudi Arabia. In addition to that, the research will find the underlying cause of the factors that cause employees working at construction sites to incur injuries ranging from fatal to minor injuries.

Hypotheses Formulation

A survey conducted to test the findings on the cause of accidents in the construction industry in Saudi Arabia at different levels consisted of a random sample of 100 participants. The mean value of participants participating in the study was 45 with a standard deviation of 18 of the population. A 5% level significance test was conducted to test the validity of the assumption. Then, hypotheses were formulated to guide the study on the need to investigate the cause of accidents in the construction industry in Saudi Arabia as flows:

- Ho: Failure to apply safety laws in the construction industry has increased the rate at which accidents occur in the construction

- H1: Applying the law does not minimize the rate of accidents in the construction industry.

Defining the test variable as X, then:

- Ho: µ=45 (Applying the law at the construction sites minimizes accidents)

- H1:#45 (Applying the law does not minimize the rate of occurrence of accidents in the construction industry)

A test statistic of a sample size of 100 used in the study had a large value of n. Thus, borrowing from the central limit theorem (Fischer, 2010) shows that the expression follows the format below:

X~N (µ, α2/n) where the value of α=18 and n=100.

According to Fischer (2010), the central limit theorem is used to estimate the above test findings to a normal approximation.

A 5% two tailed significance test provides the level of test for use in the findings.

Suppose Ho is true, then µ=45. Thus, the test is to establish if a change in the value of µ occurs, then X~N (45, 182/100).

On the other hand, Ho can only be rejected if z<-1.96 or z>1.96, implying that the modulus of z, |z|>1.96.

From these calculations, z=1.888, where |z|<1.96, hence confirming the hypothesis that the need to apply the law for construction work safety cannot be disputed.

On the other hand, further mathematical analysis needs to be conducted on different test sizes of test samples and the sampling technique tested for the validity of the samples used in the study. Further to that, the above test follows a normal distribution, thus the distribution of the test samples have to be verified against an appropriate statistic technique.

Research Instrument

To capture data for use in the study, various research instruments have been proposed both in theory, practice, and applied in different situates in the construction study. The research will primarily be based on observations that constitute the nature of work in the construction industry.

Validations

Data collection can be validated for accuracy by employing various data validation techniques. The validity of information captured when conducting interviews is also important in contributing to the validity and integrity of information gleamed for the research.

Interviews

According to Trochim (2006), Interviews provide an important component in capturing qualitative data from respondents and forms one of the most flexible tools in capturing varied data. Among the varied forms of an interview are in-depth interviews. In-depth interviews will be sued to capture detailed data from the respondents based on the varied nature of construction work in the construction industry in Saudi Arabia. Typically, in-depth interviews could be used to obtain information of on the actual causes of accidents in the construction industry ranging from fatal injuries to minor injuries incurred in the construction industry.

It is important to note that the majority of employees at the operational level are mainly artisans and easily in contact with the machinery and other work related activities making them more susceptible to the risk of accidents.

Questionnaires

Another data-capturing tool commonly used in research is a questionnaire. The questionnaire is a study design that is user friendly and should be tailored to maximize the response rate from the participants. On the other hand, relevant data from the use of questionnaires is on the causes of accidents in the construction industry in Saudi Arabia (Xiao, 2002). Thus, the questionnaire was developed for the common causes of accidents in the construction industry as the frame of reference with special emphasis on artisans and other employees or workers who spend more time at the construction site. According to Xiao (2002), questionnaires have the advantage of capturing fresh data and information from respondents. That is typical because the information is fresh and clear in the minds of the respondents. In addition to that, administering questionnaires to the respondents has the likelihood of capturing accurate data or information from the participants minimising the likelihood of distortions.

The questionnaires were designed to help capture information and data on the common causes of accidents in the Saudi Arabian construction industry, which range from fatal to minor accidents. Another data gathering method used in the study were direct observations.

Direct Observations

Direct observations formed part of the tools used in the study to capture information and data on-site on common causes of accidents in the construction industry and the rationale to incorporate the use of safety laws to protect the worker against such accidents. On the other hand, Direct observations are unconstructive and constitute accurate recording of data at the actual site and occurrence of events. However, the approach should be probabilistic as the probability of the occurrence of an accident at a particular day, event, time, type, and with a specific employee is highly unpredictable. However, according to Noor (1992), direct observations lead to a clearer understanding of the actual cause of the direct cause of an accident and the extent of the damage caused by the accident on an individual. However, several studies show that well-conducted research should evaluate the research instruments used in the inquiry for their accuracy and appropriateness in the study. Thus, the need to evaluate the reliability of the research instruments used.

Reliability of Research Instruments

The use of questionnaires poses the risk of biasness related to the human factor. Typically, that is because the research instrument should show both internal and external consistency. On the other hand, Kaming et al, (1998) and Trochim (2006) agree that the internal and external consistency of a research variable assesses the reliability of the instrument used to capture data. According to Meepol and Ogunlana (2006), the commonly agreed value of internal and external consistency is 0.6. Thus, the value is expressed mathematically as follows:

α = k cov /var

1 + (k – 1)cov / var

In the above expression, k represents the number of items or accidents on the scale, cove represents the covariance of between the accidents and common causes, and var represents the variance of the accidents and the common causes of the accidents. Thus, the mathematical expression can be simplified into the following expression:

α = kr

1 + (k – 1)r

The value of r in the above expression correlates with the common causes of accidents in the Saudi Arabian construction industry. After having evaluated the reliability of the research instruments used for data capturing, it is important to review methods used to administer questionnaires to the respondents in the construction industry.

Procedure for Administering Research Instrument

Specially trained field assistants were given the responsibility of administering questionnaires to the respondents. This method of administering questionnaires was expensive but was favored, as the most appropriate as it could afford the participants the chance to get classifications on issues not well understood in the questionnaire by the respondents. It was therefore the responsibility of the researcher to extensively tutor the field assistants on the content of the questionnaires and equip them with appropriate knowledge to respond to any questions arising during the exercise. The type of observation instrument employed for the work study is a modified data collection procedures manual developed by Pennsylvania State University and Dundee University (Thomas et al., 1987 cited in Talhouni, 1990). The direct continuous observation approach was adopted to collect data on the construction sites. As practically as possible, every minute of the work day was monitored in the continuous observation method. However, steps were taken to ease the tediousness of the data collection exercise by recording only the working time of the employees incurred injuries (Noor, 1992). The resulting data was then analysed after collections using appropriate data analysis tools.

Data Analysis Tools

To achieve the objectives of the study in investigating the cause of accidents in the construction industry in Saudi Arabia, data analysis instruments were carefully selected given the kind of data collection instruments used. The following include tools sued in the study for data analysis:

Relative Importance Index (RII)

Relative Importance Index (RII) is a tool used to evaluate the factors that contributed to the common cause of accidents in the construction industry in Saudi Arabia. In addition to that, the research instruments, Relative Importance Index (RII), was used to assign values to the common causes of accidents in terms of the level of significance of the factors. Thus, the priority afforded the faros that are the common causes of accidents are exemplified in the following expression:

5 5

RII = ∑wixi / ∑xi (1 ≤ RII ≤ 5) (Kazaz et al., 2008)

i = 1 i = 1

In the above expression, wi represents the number or weight of each factor that contributes to the cause of accidents in the industry in question. The scale is assigned numerical values ranging from 1 to 5. Each value has a specific weight with specific implications on the impact of the factor leading to the occurrence of an accident in the industry in question.

Spearman’s Rank Order Correlation

Spearman’s Rank Order Correlation measures the degree of correlation between the variables that are specific causes of accidents in the construction industry. According to (Eze et al., 2005), Spearman’s Rank Order Correlation was used to determine the degree to which the variables contributed to the occurrence of accidents in the construction industry and the perception of factors affecting the frequency with which industry accidents occur. On the other hand, given the nature of the data collected from the construction industry, and SPSS version 18 was used to analyze the data.

On the other hand, another tool used to analyse data to determine the common cause of accident of accidents in the construction industry were neural networks.

Analysis/Neural Networks

Regression Analysis/Neural Networks

A multiple regression analysis provided the capability to analyse the common causes of accidents as identified both in the literature review by using regression models to test various occurrences of accidents and the connection between the variables and the cause of accidents in the construction industry in Saudi Arabia. Thus, the regression model is represented in the following expression as shown below.

Y = bo + b1X1 + b2X2 +…+ bnXn (Choy and Ruwanpura, 2006).

According to the above regression model, there are several variables included in the model. According to the model, X2 and X1 are accident situations with respective coefficients. There was the need to conceptualize research variables in the study.

On the other hand, it is important to select activities to subject to the study based on the kind of research under consideration.

Activity Selection

Several construction activities take place in the construction industry. These activities, if wrongly executed these activities lead to the cause of fatal or minor injuries in the construction industry. Talhouni (1990) outlines the procedure for selecting activities related to accidents in the construction industry particularly which may include:

- The ease of access to the construction site and availability of the construction site from which data collection activities take place.

- Activities that are labour-intensive and have a high vulnerability of subjecting the worker to accidents.

- Activities that require a method of construction that requires the use of equipment such as ladders and other construction equipment.

- Activities with clearly identifiable gangs working together and likely to cause injuries to one another.

- Activities that take long to execute expose the worker to more working hours hence high susceptibility of risk.

- Activities situated in high-rise buildings.

Variables Used in the Study

Several variables identified for use in the study included variables that had strong correlations with the susceptibility of exposing a worker to an accident. These factors traverse the management level, the project level, and the operational level activities, which have a strong relationship between the occurrences of events that subject an employee to the likelihood of incurring an accident at the workplace.

Work and management related variables (Andreoni, 1986).

References

Abu, A. M., 2007. Developing a Model for Integrating Safety, Quality and Productivity in Building Projects in Gaza Strip. Master Thesis. Islamic University of Gaza. Palestine.

Agarwal, P. and Everett, J.1997. Strategies for Construction Contractors to Reduce Workers Comp. Costs, Journal of Management in Engineering, Vol. 13, No. 5, pp. 70-75.

Aksorn, T. and Hadikusumo, B.H.W. 2008. Critical Success Factors Influencing Safety Program Performance in Thai Constriction Projects, Safety Science, Vol 46, pp 709-727.

Al-Jarallah, M., 1984. Construction Industry In Saudi Arabia ” Journal of Construction Engineering and Management, ASCE, Vol. 109, No. 4, pp. 355-367.

Andreoni, D., 1986. Cost of occupational accidents and diseases. Geneva, International Labour Organisation, Occupational Safety and Health Series 54.

Ashford, N.A. 1976. Crisis in the Workplace: Occupational Disease and Injury. Cambridge, Mass: MIT Press.

Baig, M. 2001. Safety Assessment of Industrial Construction Projects in Saudi Arabia, Master Thesis, King Fahd University of Petroleum and Minerals, Dhahran, Saudi Arabia

Biggam, J. 2008. Succeeding with Your Master’s Dissertation – A step-by-step handbook. Berkshire, England: Open University Press.

Bouma, G. and Atkinson, G. 1995. A Handbook of Social Science Research: A Comprehensive and Practical Guide for Students. UK: Oxford University Press

Bu-Khamsin, M. A., 1999. Safety Performance Measurements: A PC Evaluation Tool for Industrial Contractor in Saudi Arabia, Master thesis, King Fahd University of Petroleum & Minerals, Dhahran, Saudi Arabia..

Burke, S. 2011. The Only Way is Up. Web.

Chua, D.K., and Goh, Y.M. 2004. Incident Causation Model for Improving Feedback of Safety Knowledge, Journal of Construction Engineering and Management, Vol. 130, No. 4, pp. 542-551.

Choy, E. and Ruwanpura, J.Y. 2006. Predicting Construction Productivity Using Situation-based Simulation Models. Canadian Journal of Civil Engineering 33: Web.

Everett, John, G. 1999. Overexertion Injuries in Construction, Journal of Construction Engineering and Management, Vol. 125, No. 2, pp. 109-114

Eze, J.I., Obiegbu, M.E. and Jude-eze, E.N. 2005. Statistices and Quantitiative Methods for Construction and Business Managers. Lagos, Nigeria: The Nigerian Institute of Building.

Fabiano, B., Curr, F., and Pastorino, R., 2004. Study Of The Relationship Between Occupational Injuries And Firm Size And Type In The Italian Industry, Safety Science, Vol. 42, pp. 587-60.

Fung, Ivan W.H., Tam, C.M. Tung, Karen C.F., and Man, Ads S.K. 2005. Safety Cultural Divergences among Management, Supervisory a Worker Groups in Hong Kong Construction Industry, International Journal of Project Management, Vol. 23, No. 7, pp. 504-512.

Hassan, C.R., Basha, O.J., Hanafi W.H. 2007. Perception of Building Construction Workers Towards Safety, Health and Environment, Journal of Engineering Science and Technology, Vol. 2, No. 3, pp. 271-279.

Hatush, Z., and Skitmore, M. 1997. Criteria for Contractor Selection, Construction Management and Economics, Vol.15, No. 1, pp. 19-38

Fellows, R. and Liu, A. 2008. Research Methods for Construction. Third Edition. West Sussex, United Kingdom: Blackwell Publishing Ltd.

Jannadi O.M., and Bu-Khamsin, M. S., 2001. Safety Factors Considered By Industrial Contractors in Saudi Arabia, Journal of Building and Environment, Vol 37, No.(5), pp. 539–547.

Kartam, N., Flood, I. and Koushki, P., 2000. Construction Safety in Kuwait: Issues, Procedures, Problems, and Recommendations, Journal of Safety Science, Vol. 36, No. 3, pp. 163-184.

Kaming, P. F.; Olomolaiye, P. O.; Holt, G. D.; Harris, F. C. 1998. What Motivates Construction Craftsmen in Developing Countries? A Case Study of Indonesia, Building and Environment 33(2–3): 131–141.

Kazaz, A., Manisali E. and Serdar, U. 2008. Effect of Motivational Factors on Construction Workforce Productivity in Turkey. Journal of Civil Engineering and Management. 14 (2): 95- 106.

Kartam, N. A., 1997. Integrating Safety and Health Performance into Construction CPM. J. Construction Engineering and Management, ASCE, Vol. 123, No. 2, pp. 121-126.

Koehn, E., Kothari, R. K., and Pan, C., 1995. Safety in Developing Countries: Professional and Bureaucratic Problems, J. Construction Engineering and Management, ASCE, Vol. 121, No. 3, pp. 261-265.

Low, S. P. 1989. An evaluation of quality in construction, The Professional Builder, Singapore Institute of Building, 4(1):28-36.

Low, S. P. 1990. The organization of construction export marketing: Theory and Practice, Journal of Real Estate and Construction, 1(1):82-98.

Low. S. P. 1990. Global construction industry: The North-South divide, Habitat International, 14(4):97-117.

Low. S. P. 1990. A study of the construction industries in ASEAN: 1970-1984, In Proceedings of the First Asean International Symposium on Construction and Development, organized by the Asean Constructors Federation, 7-8th May, Kuala Lumpur, Malaysia, pp.126.

Low. S. P. 1990. World markets in construction: I. A regional analysis, Construction Management and Economics, 9(3):63-71.

Low. S. P. and Goh, K.H. 1992. Quality assurance in construction: The engineers’ perspective in Singapore, Cost Engineer, Association of Cost Engineers, 30(4):8-11.

Low, S. P and Goh, K.H. 1992. Construction quality assurance: an architectural perspective in Singapore, The Professional Builder, Singapore Institute of Building, 7(4):31-38.

Low, S. P and Goh, K.H. 1993. Implementing QA in a newly industrializing economy: The case of Singapore, Construction Papers Series, Paper No.20, Chartered Institute of Building, 8pp.

Low S P and Goh, K.H. 1993. The practice of quality and quality assurance in the Singapore construction industry, Quality Forum, Institute of Quality Assurance,19(1):40-45.

Mohamed, S. 2002. Safety Climate in Construction Site Environments, Journal of Construction Engineering and Management, Vol. 128, No. 5, pp375-384.

Mattila, M., Hyttinen, M., and Rantanen, E., 1994. Effective Supervisory Behavior and Safety at the Building Site, International Journal of Industrial Ergonomics, Vol. 13, No. 2, pp. 85-93.

Naoum, S.G. 2007. Dissertation Research and Writing for Construction Students. London: Elsevier Ltd.

Ng, S.T., Cheng, K.P., and Skitmore R.M. 2005. A Framework for Evaluating the Safety Performance of Construction Contractors, Building and Environment, Vol. 40, No. 10, pp. 1347-1355.

Noor, I. 1992. A Study of the Variability of Labour Productivity in Building Trades. Ph.D. Thesis, Department of Civil Engineering of the University of Dundee.

Olsen, C. and St. George, D. M. 2004. Cross-Sectional Study Design and Data Analysis. The Young Epidemiology Scholars Program (YES). Web.

Sawacha, E., Naoum S., and Fong, D. 1999. Factors Affecting Safety Performance on Construction Sites , International Journal of Project Management, Vol. 17, No. 5, pp. 309-315.

Saudi Aramco, 1995. Saudi Aramco 1994 Loss Control Report. Al-Mutawa Press, Dammam, Saudi Arabia.

Seymour, D. E. and Low, S.P. 1990. The quality debate, Construction Management And Economics, 8(1):13-29.

Shash, A., and Abdul-Hadi, N. 1993. The Effect of Contractor Size on Mark-up Size Decision in Saudi Arabia, Construction Management and Economics, Vol. 11, pp. 421- 429.

Tam, C.M., Zing, S.X., and Deng, Z.M. 2004. Identifying Elements of Poor Construction Safety Management in China, Safety Science, Vol. 42, No. 7, pp. 569-586.

Teo, E.A.L., Ling, F.T.Y., and Chong, A.F.W. 2005. Framework for Project Managers to Manage Construction Safety, International Journal of Project Management, Vol. 23, No. 4, pp. 329-341.

Trochim, W.M.K. 2006. Research Methods Knowledge Base, Institutions. Enugu, Nigeria: John Jacob’s Publishers. Web.

Xiao, H. 2002. A Comparative Study of Contractor Performance Based on Japanese, UK and US Construction Practice, PhD Thesis, SEBE, University of Wolverhampton, Wolverhampton.