Summary of the Case

The targeted case study outlines the major issues affecting Tehindo’s supply chain management (SCM). The company produces and markets two types of tea products to its consumers. These products include “ready-to-drink fruity tea and ready-to-drink jasmine tea” (Pujawan & Er, 2009, p. 221). Each category encounters several challenges in the market. The case study shows how Tehindo has become a leading manufacturer and marketer of various tea flavors. However, some challenges in the firm’s supply chain are affecting its business potentials. This essay describes the nature of these problems and offers succinct solutions that can be used to improve Tehindo’s supply chain processes.

Problem

The distribution manager (DM) believes strongly that some of the products have failed in the market. However, the marketing manager argues that every product has the potential to support the company’s goals. Some issues such as information distortion, poor coordination, and handing of bottled products have made it impossible for the firm to achieve its business potentials (Pujawan & Er, 2009). The company also requires new strategies to achieve its business potentials. This fact explains why the second meeting should deliver the most appropriate solutions and ideas to streamline Tehindo’s supply chain processes.

Identifying Issues and Describing Alternative Solutions

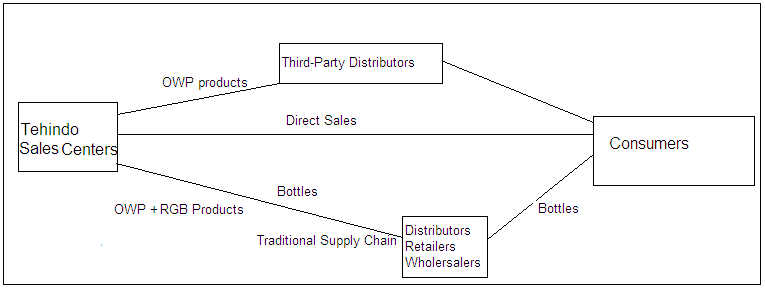

The supply chain configuration of Tehindo and the flow of products and information within the supply chain

The bottled Goteh and Fteh in terms of challenges in managing their supply chain processes

The first issue facing the firm arises from the unique challenges affecting the supply chain processes for Fteh and Goteh. For instance, Tehindo encounters several challenges in managing its supply chain processes. Such challenges are determined by the nature of the targeted product. For instance, bottled Goteh is widely consumed compared to Fteh. The smooth flow of Fteh is more challenging because of its diverse consumers.

Fteh encounters numerous challenges such as inaccurate forecasts and forward buying. Such issues result in a “shortage of empty bottles at the factories” (Pujawan & Er, 2009, p. 223). Although bottled Goteh faces similar challenges, it is notable that accurate forecasts can be made thus improving the performance of the product. Bottled Fteh has eight flavors while Goteh has one. This situation makes it hard to manage the supply chain process for bottled Fteh.

The causes of temporary demand (and order) increases in this supply chain

The firm also faces temporary order and demand increases. There are specific factors that cause temporary demand increases in the firm’s supply chain. To begin with, the company announces a possible price increments two weeks earlier. This approach encourages “retailers and wholesalers to engage in forward buying” (Pujawan & Er, 2009, p. 224). This strategy increases the demand for different products. As well, various celebrations and events such as New Year and Christmas result in temporary demand. More customers tend to consume such products in large numbers during these celebrations.

Possible suggestions of the company’s supply chain manager

The purpose of the second meeting is to determine the fate of different variants of the fruity tea (also called Fteh). As the Supply Chain Manager, it would be appropriate to support the production of these variants. The outstanding fact is that each flavor or variant has its potential consumers. Prospects also indicate clearly that the firm will attract more young consumers and eventually increase its revenues.

The company has also managed to produce a superior brand that fulfills the needs of many teenagers. That being the case, the best suggestion is to continue producing the major variants of the fruity tea. This move will ensure the firm has diversified products. The important thing to do will be to sensitize more people about these variants using different promotional and advertising strategies. The firm should also coordinate every supply chain, identify different channels, and embrace new marketing strategies. Such approaches will eventually turn such products into cash cows (Simchi-Levi, Kaminsky, & Simchi-Levi, 2008).

Possible suggestions to reduce distortion of information in the supply chain

The case study shows clearly that the presence of information distortion is something that affects the integrity of the supply chain. For instance, the company increases prices temporarily thus affecting the ordering patterns of different wholesalers and retailers. As well, the supply chain process does not have a coordinated strategy to deal with the problem of information-sharing. The Supply Chain Manager should, therefore, identify new strategies to improve the nature of communication throughout the distribution process (Naslund & Williamson, 2010). This practice will reduce the current issues affecting the firm and eventually improve the performance of different products.

The advantages and disadvantages of vertical integration and outsourcing for Tehindo

Tehindo uses vertical integration and outsourcing to support its supply chain processes. To begin with, the approach is advantageous because it has the potential to increase the level of coordination. Supply chain practices are conducted professionally thus increasing business performance. Outsourcing is also used to ensure more products are marketed to targeted consumers. However, these practices present various disadvantages.

For example, vertical integration reduces the level of competition (Konecka, 2010). One member of the supply chain might fail to act efficiently thus affecting the level of performance. The outsourcing process also makes it impossible for Tehindo to offer direct sales to its customers. The company only markets its products to different consumers who place large orders (Pujawan & Er, 2009). This practice fails to support the needs of different Fteh and Goteh consumers.

Justifying Recommendations for Each Question

The above analysis identifies the nature and complexity of the major issues facing Tehindo. The suggested recommendations can make it possible for the firm to streamline its supply chain activities. The company can also use the best supply chain processes to achieve its business goals (Pujawan & Er, 2009). To begin with, the best solution is to address the major challenges facing the supply chain processes for Fteh. This is the case because many consumers are unable to purchase the product due to poor inventory practices. Proper information sharing and coordination will ensure the major variants of the brand are stocked by every dealer. As well, the firm should ensure the best channels are used to support the marketing process for Goteh.

The other concern arises from the temporary demand in the firm’s supply chain. This problem arises from the changing consumer demands and price-setting practices. The firm should use new measures to encourage more retailers and wholesalers to return their bottles (Felea & Albastroiu, 2013). This goal can be achieved by hiring third-party distributors to manage every logistical operation. This move will ensure more wholesalers have access to the products and eventually increase the level of profitability.

It will also be appropriate to support the performance of Fteh in the market. It is agreeable that various Fteh variants have been performing positively in the market. The decision to do away with this brand will affect more teenagers who are accustomed to the brand. As well, the move to support the products will attract more consumers in the future and eventually make the firm successful. The availability of different products increases a company’s competitiveness (Felea & Albastroiu, 2013). Similar supply chain approaches should also be embraced for Goteh. This move will attract more consumers and support the company’s profitability.

Supply Chain Managers (SCMs) have the potential to transform the nature of communication in every distribution channel (Felea & Albastroiu, 2013). The SCM will ensure different distributors and retailers collect the required information and convey it to the company. The firm will use the gathered information to make the best production and distribution decisions (Done, 2011). Every person in the supply chain process should also be equipped with the best ideas and concepts. Information sharing within every supply chain process is critical towards the success of an organization.

Finally, Tehindo should reconsider the issues associated with the use of vertical integration and outsourcing. These practices have for years supported the company’s supply chain processes. The firm has managed to market more products to its customers. It will be appropriate for the company to coordinate various supply chain activities to deliver the right stock to different customers (Simchi-Levi et al., 2008). Every outsourced distributor should also be aware of the changing needs of different consumers. This knowledge will make it possible for the company to formulate quality decisions. Such decisions will eventually make Tehindo successful. These efforts will support the distribution of both Fteh and Goteh products.

Reference List

Done, A. (2011). Supply Chain Knowledge Management: A Conceptual Framework. Working Paper, 1(1), 1-23.

Felea, M., & Albastroiu, I. (2013). Defining the Concept of Supply Chain Management and its Relevance to Romanian Academics and Practitioners. Amfiteatru Economic, 1(1), 74-88.

Konecka, S. (2010). Lean and Agile Supply Chain Management Concepts in the Aspect of Risk Management. Electronic Scientific Journal of Logistics, 6(3), 23-31.

Naslund, D., & Williamson, S. (2010). What is Management in Supply Chain Management: A Critical Review of Definitions, Frameworks and Terminology. Journal of Management Policy and Practice, 11(4), 11-28.

Pujawan, N., & Er, M. (2009). Managing Supply Chain Complexity in a Tea Manufacturing Company. Integration Issues, 1(1), 221-226.

Simchi-Levi, D., Kaminsky, P., & Simchi-Levi, E. (2008). Designing and Managing the Supply Chain. New York, NY: McGraw Hill.