Introduction

The expansion of global business-to-business marketing stimulated by globalization, internet and trade agreements accentuates the importance of supply chain. Logistics has gained strategic importance for both the management and academicians as it is an integral part of the supply chain and ensuring an organization’s overall success (Logistics Service Quality as a Segment Customized Process, 2001). Further, as raw materials sources, production facilities, and consumer markets are distributed globally, international logistics assumes a strategic position.

Global economic development has resulted in an increase in demand for transport services. International logistics is especially crucial to the high-value chemicals industry, since raw materials sources, production facilities, and consumer markets are distributed globally (Erera, Morales and Savelsbe 2005).

Global transportation industry has gained improved efficiency in transportation of bulk goods due to the availability of containers in the transportation business (Konings and Remmelt 2001). There has been a considerable increase in freight shipments for the past 10 years. During 2000 and 2004, global container transport capacity has increased by 10.6% annually and till the January of 2005; container transport capacity order by global liners went up 32.8%. (MOFCOM 2007). Considering only the chemical industry, the global increase in demand for intermodal transport has increased by almost 10 percent annually on an average (Erera, Morales and Savelsbe 2005).

Annual growth of tank containers being shipped from the United States to Europe and from Europe to the US, as well as from the US to Asia, is projected to grow up to five percent till 2011 (ITCO 2006b). Although the study did not address the use of tank containers travelling from Asia to the US, industry representatives estimate that annual growth could top out as much as five percent, as well. Similarly, the use of tank containers in Europe and on most other deep sea routes worldwide is projected to expand by as much as five per cent per annum.

Driven by the commissioning of new chemical production plants, particularly in China, tank container trade levels on the Asia to Europe route are set to expand by 5-10 per cent per annum over the next five years, while the annual growth in the intra-Asian movement of chemicals using tanks will exceed 10 per cent (ITCO 2006a).

International transport of liquids is conducted using five major modes: pipeline, bulk tankers, parcel tankers, tank containers, or drums. Pipeline and bulk tankers are used primarily in the petrochemical industry for the transport of large quantities of a single product. Parcel tankers are smaller vessels with up to 42 tank compartments and are used to simultaneously transport multiple cargoes. Tank containers, also referred to as ISO tanks, intermodal tanks, or IMO portable tanks, and are designed for intermodal transportation by road, rail, and ship. Tank containers are also used for intermodal transport of gas cargoes.

The primary problem with these containers is disposing of them once transportation of the product is completed. The reason for this problem is that products are rarely produced and consumed in the same place. Tanks containers are loaded and unloaded at different places, due to which transporting the empty containers are unavoidable. This is a persisting problem in the container transportation and the trade imbalance flows in the economy makes this issue more critical for container carriers.

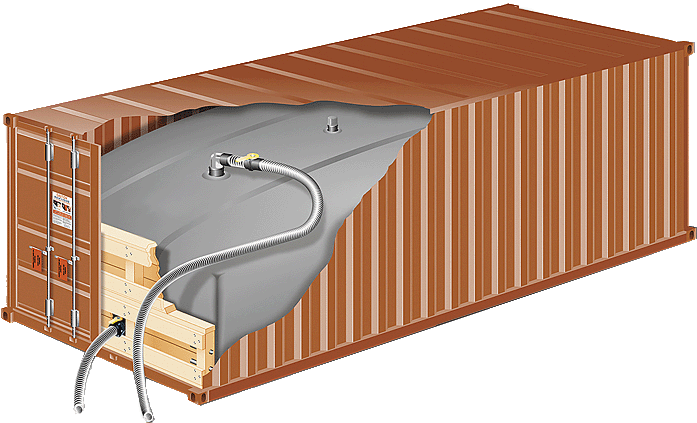

It has been estimated that the cost of transportation of empty containers on sea is about 21 percent of all containers transported and on land the estimate is around 40 percent (Konings and Remmelt 2001). Flexi-tanks are an answer to this increasing cost of transportation of empty tank containers. It is a fairly modern concept in logistics as a substitute for drums, totes, and ISO tanks containers. These are large bags which are made of polyethylene and are ideal for transport of non-hazardous liquid products in ISO standard shipping containers. There are two varieties of flexi-tanks: first is a reusable polyethylene (PE)-based flexible bags and the second is a single use, recyclable flexi-tanks for the carriage of liquid products.

Despite its perceivable advantages, shippers still prefer ISO tanks, IBS, and/or drums for transportation of liquids. Freight forwarders are sceptical of using Flexi-tanks and shippers decline to even try this concept. This has been a major bottleneck in flexi-tank business. The study, Longer Term Trends and Developments of the Tank Container Industry, was conducted by Erasmus University in Rotterdam, the Netherlands. Interviews were carried out with senior logistics managers at Europe’s 10 leading chemical manufacturing companies (Erera, Morales and Savelsbe 2005).

The study showed that all the manufacturers make extensive use of tank containers, among a number of bulk and packaged goods transport options, in their supply chain operations. The report’s authors found that for deep-sea movements on intercontinental routes chemical producers favour tank containers over the drum, intermediate bulk container, and flexitank options in many applications for safety, efficiency, and environmental protection reasons (Erera, Morales and Savelsbe 2005).

The purpose of this paper is two-fold: first, it investigates into the potential problems in marketing of flexi-tanks which are curbing the ready acceptance of the product and the second is to analyze the reasons behind customer scepticism regarding the product. Hence the research questions that the study tries to address are:

- What is the customers’ perception regarding flexitanks? Are there any gap in the customer perception and the information provided in product brochures?

- What are the marketing barriers to acceptance of flexitanks by freight forwarders or shippers of liquids?

- How helpful will be educating the customers in marketing the products?

In order to embark on a study of flexitanks’s marketing barriers, it is important to understand the background of the global freight transportation market and liquid transportation in the next section.

Research Background

Container shipping transportation internationally has gained immense economic success in the last decade. The sector experienced a growth of 10 percent per annum between 1990 and 2005 on an average. The growth in 2005 was more than 11 percent. The growth rate was higher than that of the overall sea transportation and also of the air transportation sector. (Deutsche Bank 2006) Deutsche bank research forecasts a growth of 9 percent on an average till 2015 (Deutsche Bank 2006). With rapid increase in transportation of cargo in containers, the demands for various types of containers are in arising.

Tank containers are considered expensive transport equipments to make, purchase and operate (ITCO 2006b). This is almost 5 times more than the cost for a standard GP container. The capital cost for these equipments has made it difficult for any tank container operator to deploy a large inventory of ISO tank containers. Typically, 60% to 70% of the fleet is owned by the operator; the remaining tanks are leased, usually for periods of 5 to 10 Years. (Erera, Morales and Savelsbe 2005).

Tank operators provide empty tanks at the customer’s origin plant and arrange transportation after loading across multiple modes to the final destination. In order to achieve optimum fleet utilization and to avoid their capital being tide-up, tank operators do not keep their empty units idle to meet market expectations and they usually try to keep them in a moving cycle to generate income. As a result, the supply of tank containers to the shippers maybe delayed due to non-availability of empty units. In such cases, there are usually two different supply strategies :

- In-bound /out-bound planning, which means that the shipper has to wait for the next import shipment to the port of loading to re-use the cleaned ISO tanks.

- Reposition planning or shipping the empty units from another ISO tank container depot to the Port of Loading.

The first option leaves the shippers at the mercy of the operators. There could be no precise schedule or timetable for releasing empty tank units for outbound shipment. Shippers may encounter extensive delays to receive empty equipments. The other issue is the cleaning process. Not all the countries and ports have cleaning facilities to clean ISO tanks containers. Empty tanks might have to be shipped to a cleaning facility somewhere else, which means more time and money. Repositioning tanks is a common practise, but handling and transportation costs have to be covered by some party and that happens to be the shipper.

As fuel and transportation costs continue to rise, flexitanks are increasingly providing an important alternative to transporting liquids in tank containers, IBCs or drums. The use of flexi-tanks offers an economic alternative to the conventional systems used in the packaging and transportation of bulk liquids (Bulk Transportation 2007). Being portable and highly mobile, the flexi-tank converts a 20 ft standard ISO container into a bulk liquid transport unit. With flexi-tanks, bulk liquid cargo is transported at standard box rates. In addition, flexi-tanks can be insulated against both heat and cold and specialized flexi-tank equipments can be used in refrigerated box containers, allowing shippers to transport juices, juice concentrates, etc at controlled temperatures.

The new generation of single-trip disposable flexi-bags has more advantages that are economical for customers and carriers, since they do not have to pay tank cleaning or repositioning costs.

According to ITCO survey, due to an increase of around 6 percent on an average since 2003 in chemical industry, there has been an increase in freight forwarding and transportation of liquid (World Cargo News 2007). The Erasmus team found that the use of tank containers in Europe and on most deep sea routes worldwide is expected to grow by up to 5% per annum over the next five years. Certainly, the established and comparatively well balanced transatlantic trades are forecast to continue to grow at this rate into the next decade. In Asia, the region with the most potential growth in chemical shipments, the prospects for tanks are much brighter, albeit from a smaller, less mature base.

Driven by the commissioning of new production plants, particularly in China, tank container trade levels on the Asia to Europe route is forecasted to expand by 5-10% per annum over the next five years, while the annual growth in the intra-Asian movement of chemicals using tanks will exceed 10% (Bulk Transportation 2007). As with the Europe-Asia trades, tank container movements from Asia to the US are forecast to outweigh shipments in the opposite direction by a factor of 2:1. When considering all these deep sea trade flows from a global perspective, the repositioning of empty tanks back to Asia for new loads presents a major challenge for tank logistics service suppliers. Newly delivered units from the Chinese tank manufacturing plants are in great demand for loading their maiden cargo for distribution to world markets.

Finding paying cargoes for the tanks’ return journeys to Asia in order to load product from the region’s vast new petrochemical complexes is proving to be extremely difficult. The imbalance is also preventing the optimisation of the full economic potential of the tank container and raises the spectre that flexitanks could possibly win business from tank containers in the non-hazardous liquids sector. The reasoning here is that it is much easier to find cargo for a standard container being repositioned back to Asia than for a tank. Empty flexi-tanks are flexible and, soft, smooth, collapsible and lightweight for storage and transport.

Problem Statement

“In the door-to-door bulk liquid transportation industry, the modern ISO stainless steel tank container reigns supreme in terms of safety, reliability, durability, and environmental friendliness.” (Stolen 2008) Even though flexi-tanks have advantages over ISO tanks, they are not that well accepted among shippers. The early bags were not re-usable. So the cost of using the tanks once and reuse them was too high. Further, there were numerous occasions of tank leakage which reduced their demand in the market. Earlier the tanks were made with polyethylene but now they have been completely restructured. Even then, the demand for the product is not picking up. This paper aims to answer the following problems:

- To investigate reasons for commercial reluctance to use flexitanks. This is done by analysing the survey conducted in a sample of flexitanks operators.

- To enumerate the information provided by flexi-tank manufacturers and operators to customers and evaluate their sufficiency in comparison to the problems faced by flexitank users as revealed by the survey results.

- Comparing the cost of flexitanks as provided by flexi-tank operators with other containers such as IBCs and drums.

Significance

The study will help in the expansion of flexitank demand in the market. This will aid the flexitank manufacturers to understand the fault areas in their marketing of the tank vis-à-vis ISO tanks. This will also help flexi-tank operators to identify possible commercial barriers to the acceptance of flexitanks and remove them in order to gain more market share. This study identifies the bottlenecks in the marketing process and will help in removing them. Moreover it identifies the target industries and products which should be targeted to sell the product.

Research plan

This paper is divided into five sections. The first section enumerates the topic in an introductory sub section followed by a brief understanding of the research problem, plan and methodology that is intended to be adopted. The second section enumerates the theoretical background of b2b marketing. Here the role of the buying group is enumerated and we try to establish a link between the individuals and what can influence them.

Then we try to understand the theoretical basis for non-adoption of a new technology as has been enumerated in the literature. After which we see how educating the customers can boost adoption and acceptance of the product. Then we go through a detailed understanding of the product i.e. flexitank. Here we try to answer questions like how, where, and why regarding flexitanks.

In this section we also discuss the relevant methodologies which can be adopted for evaluating marketing materials. The third section we a detailed analysis of the methodology that will be adopted in the research. It is divided in discussion the techniques thus used, i.e. questionnaire survey of user and non-users of flexitank, and the methodology adopted to evaluate the various marketing materials. It enumerates how the primary data is collected for research.

Then in the next subsection, the data analysis of the survey questionnaire and the marketing materials are done. In the fourth section we do an analysis of the data analysis and try to summarize our findings and align the findings according to the research questions. Here we provide the limitations and the recommendations for future research. In the sixth section we draw a conclusion to the study.

Theoretical Background

The marketing strategy in the case of industrial or business-to-business (B2B) marketing is much different from business-to-consumer (B2C) marketing. Industrial buying involves a group of individuals who influence or take the buying decision while in case of B2C the target customer is one, clearly making the former a more complex process and target to attain. An understanding of the organizational buying process is fundamental for evaluation of industrial marketing policies. In this section we evaluate different industrial buying factors and how they affect buying behaviour of industrial purchasers. In this section we also try to understand the barriers to switching in case of industrial buying and how a switching can actually be affected.

Industrial Buying Decision

Industrial buying is different from normal B2C marketing. Buying decision-making in enterprises can be characterized by the process of interaction patterns, decision-making processes, conflict resolution mechanism, and a number of other elements between or within groups. The interaction patterns are better analyzed in the context of four variables influencing the buying decisions (Katrichis 1998): power, specific buying influence, share, and commitment.

In the case of industrial marketing there is less number of customers and there are several buying influences as the purchasing decision is taken by many people as there exist a buying committee which influences the buying decision of the organizations. Webster and Wind (1972) call the decision making unit of a buying organization of the buying organization the buying centre. It is composed of “all those individuals and groups who participate in the purchasing decision-making process, who share some common goals and the risks arising from the decisions” (Webster and Wind: 78) the buying centre includes all the individuals in the organization who influence the selection of suppliers:

- Initiator: those who request that something be purchased. They must be the users or others in the organization.

- Users: Those who will use the product or service. In many cases the users initiate the buying proposal and help defining the product requirements.

- Influencers: People who influence the buying decision. They often help in providing specifications and also provide information for providing alternatives. Technical persons are usually important influencers.

- Deciders: People who decide upon product requirements or on suppliers.

- Approvers: People who authorize the decision of the deciders or buyers.

- Buyers: people who have formal authority to select the supplier and arrange the purchase terms. Buyers may help shape product specifications, but they play their major role in selecting vendors and negotiating. Gatekeepers: People who have the power in preventing the sellers or information to reach the buying centre. For example, purchasing agents. (Webster and Wind 1972)

The above individuals have to be identified and targeted individually to initiate the purchase decision. So the individuals who influence the buying decision have to be identified, and then approached with the specific kind of information each need.

Adoption/Non-Adoption of Innovation in Organizations

The process of adoption in an organization is a series of sequences which a potential adopter of an innovation passes through. Rogers (1995: 21) defines the adoption process as ‘‘the process through which an individual or other decision-making unit passes from first knowledge of an innovation, to forming an attitude toward the innovation, to a decision to adopt or reject, to implementation of the new idea, and to confirmation of this decision.’’ In case of organizational buying, there are two stages: initiation and implementation (Zaltman, Duncan and Holbek 1973).

Late adopters usually accepted products on getting more information and on better experience to the product. As such, late adopters are generally supposed to be risk averse. Even if the risk perception among individuals is different, the decision-making process which causes final adoption is usually the same, according to Rogers (1995).

This model essentially encapsulated various studies on innovation adoption process (Kaplan 1991, Clark and Staunton 1994), and was used widely for explaining the adoption of information technology related products. In this model, the adoption process was divided into five phases: knowledge of innovation, persuasion, decision, implementation, and confirmation. The process begins with the acknowledgement of the existence of an innovation, which could be driven by communication and needs, among other factors.

The second stage entailed the persuasion of the innovation to be adopted. This was the phase where the factors affecting the rate of adoption would fit in. There are five dimensions which act as the main driving force of acceptance and persuasion according to Rogers which are complexity, compatibility, observability, trialability, and relative advantage. In the third stage the adopter decides whether to accept or reject the innovation after considering the persuasion factors of the innovation. Implementation stage occurs when there is a question of adoption of the technological innovation, and corroboration involved the post-adoption conduct by the adopter.

The adoption decision transpires between the initiation and the implementation stage. In the initiation stage, the organization becomes aware of the innovation, forms an attitude towards it, and evaluates the new product; it includes three sub-stages which are awareness, consideration, and intention. In the implementation stage, the organization decides to purchase and make use of the innovation. However, this organizational adoption decision is only the beginning of implementation (Frambach and Schillewaert 2002).

Our contention is to understand why Flexitanks are not being adopted by organizations. Most research focuses on the factors that enhance adoption rather than the factors that inhibit it. Research shows that concluded that ‘‘non-adoption is not the mirror image of the adoption decision.’’ (Gatignon and Robertson 1989) Some studies have focused on non-adoption but the phenomenon is complex, because the reasons for non-adoption may lie at earlier stages of the adoption process.

Potential adopters may have actively decided to reject the innovation, they may have passively decided to reject, or they may have not progressed through certain stages of the adoption process yet (Nabih, Bloem and Poiesz 1997).

As most adoption studies do not follow a process approach, little is known about the factors that affect the process prior to actual adoption (Olshavsky and Spreng 1996). Research in health psychology shows that the decision processes in adopting certain behaviour is dependent on a person’s decisional balance (Velicer, et al. 1985). This refers to the extent to which perceived positive attributes outweigh negative ones. Negative decisional balances in the early stages of the adoption process prevent potential adopters from considering adoption (Prochaska, et al. 1994).

In a study of the adoption of medical instruments by hospitals, Meyer and Goes (1988) found that organizations in later stages of the innovation process perceived the innovation as having lower risk and being less complex. Such innovation characteristics are likely to play a more important role in the early stages, whereas perceived relative advantage is more important in later stages (Labay and Kinnear 1981). Research in marketing on the influence of perceived innovation characteristics on the stages of the adoption process is scarce and indicates the need for more studies.

Given these reasons for the non-adoption of a product by organizations, now we turn to understand the reasons that help in adoption of the products. As the adoption of product is closely in addition to the dimensions that influenced adoption, the process by which individuals adopted an innovation was also crucial, as an understanding of the these two areas would be imperative for the success of an innovation. The review demonstrated the diverse studies on the process of the adoption of new innovations.

Mansfield (1961) showed that the percentage of individuals who adopt an innovation increases with the availability of higher degree of information and product experience. He segregated the population of consumers into five categories in regards to their inclination to adopt a new product. The categories can be divided as innovators, early adopters, early majority, late majority, and finally laggards (Rogers, 1995). Hence it is important to understand in which stage the flexi-tank’s customers fall. This discussion will help flexi-tank operators to understand the reasons for non-adoption of flexitanks and adoption of ISO tanks.

Role of Education in Marketing of Industrial Goods

Customer education has been defined (Gaillard-Meer 1984) as “any purposeful, sustained, and organized learning activity that is designed to impart attitudes, knowledge, or skills to customer or potential customers by a business or industry”. Customer Education is evolving as a new way of promoting products and services of the company, as it is known today that information surrounding a product is much more important than the product itself. Because of its potential outcomes in terms of sales, satisfaction, or loyalty, customer education has been steadily developed in the “business-to-business” sectors. Charles Kozoll (2000) believes that customer education gives companies a competitive edge. He adds that education comes first and leads to the act of buying.

Buyer and seller relationships have become an integral part of business-to-business operating strategies. Product complexity is also a special feature in case of industrial selling. The level of customer knowledge regarding the product plays a crucial role in buying decision-making (Johns 1999). If business customers do not have knowledge of the products and services offered, their attempts at customization may lead to inappropriate products, in turn leading to dissatisfaction and even legal actions.

For business-to-business, processes to succeed customers need to have intrinsic knowledge of the product, or customers need to be provided knowledge of the product by the distribution channel (Sharma 2005). If customers are not knowledgeable about products, effective customization emerges from the distribution channel (including salespeople) educating customers (Treacy and Wiersema 1993). Customer education increases brand loyalty which in turn lowers sales cost and increases profit (Mckey 2003).

Definition and examples of customer education show the instructional nature of customer education that can take the form of classes, seminars, training, multimedia courses (Honebein 1997). Examples also reveal the double interest of education as both a promotional activity and a product-support activity. Promotional activity means that education can help customers to better understand market offers and consequently incite them to purchase (Honebein 1997). Kozoll (2000), suggests that customers should receive information and educational material that is adequate and carefully selected by involving sales, marketing, technical service personnel and web designers before the sale because education precedes commitment.

Product-support activity means that customer education helps customers to properly use products or services they have bought. Objectives in this case are to enhance customer satisfaction with a product (Honebein 1997) to enhance relationship quality (Hennig-Thurau 2000). Rather than mechanically define customer education as either a pre-purchase or a post-purchase initiative, many authors defend the holistic interest of customer education. Honebein (1997) argues that each stage of consumer decision-making represents an opportunity for education follow the same approach. For these authors, education is indispensable to enhance every “customer-supplier” encounters.

Customer education is needed throughout the customer life cycle which consists of four main stages, including Consider, Purchase, Set-up and Use. During the Consider stage, we need to educate the customer first to become aware of the need and look for alternative solutions (Gaillard-Meer 1984). In the Purchase stage, customers need to be given information that helps them evaluate, choose, and place an order. In the third stage and while Set-up, customers need to know how to install and use the product (Honebein 1997). Finally, during the Use stage, customers require education on how to operate, maintain, and make the decision to upgrade or retire the product (Honebein 1997).

All the learning efforts customers make leads to a better level of performance. Seen from the company side, education provided to customer presents the interest to clarify the role of customers and to help properly consume products and services (Honebein 1997). The immediate consequences on productivity have been demonstrated for both services and products. Notably, education has an impact on both behavioural and attitudinal consequences: product returns, complaints, or inquiry decrease while satisfaction and loyalty increase.

Marketing Material and B2B Marketing

Marketing oriented to the corporate market (b2b), comprises activities involved in the supply of goods and/or services to corporations, which in turn use them to produce their own goods and/or services to end-users or other companies. There are several differences between b2b and business-to-consumer, especially concerning the higher risk for a corporate buyer in case of a bad purchase decision, which may affect or even end a buyer’s career. So, one of the objectives of the advertising material is:

“to give confidence to the buyer in relation to the products and the company, since the concerns about the negative consequences of a bad purchase leads the individuals to make safe purchases, looking for products from renowned vendors in the market, contacting the companies, requesting product demos and other precautions”. (Sherrington 1993, 20)

B2B buying decision being extremely complex which comprises several stages and involves many professionals as described by Bonoma and Shapiro (1983) information flow regarding the product to the decision making body in extremely important. Hence designing of a good brochure helps in unlocking the different stages of B2B marketing. One of the most relevant criteria to understanding information source usage is effectiveness of the information because it reflects how influential the information is on making purchase decisions (Murray, 1991). In general, brochures have been found to be a preferred consumer information source for a great diversity of consumer products or services including small manufacturers (Weinrauch, Mann, Pharr, & Robinson, 1991).

It is imperative to undertake an analysis of the brochure or presentations that are used by flexi-tank operators in persuading the customer to switch to flexi-tank from ISO tanks or drums.

Drums and ISO Tank Containers

Traditional mode of transporting liquids was bulk containers. Then a transition was made to using 55 gallon drums for transportation of liquids (Morris 2007). The 55-gallon drum is still our primary method for moving industrial chemicals, accounting for about 80 percent of shipments (Morris 2007). After making slow progress against the traditional 55-gallon drum for moving small-volume liquid shipments, intermediate bulk containers (IBCs) and intermodal tank containers (ISO tanks) have started to gain acceptance among freight forwarders (Morris 2007).

Tank containers, also referred to as ISO tanks, intermodal tanks, or IMO portable tanks, and are designed for inter-modal transportation by road, rail, and ship.ISO tanks are a fat tank inside a steel frame that allows it to be moved like any 20-foot box container (Figure 1).

ISO tanks have many advantages for the international transport of liquid chemicals:

- They are environment-friendly, since they are less prone to spillage during spilling and unloading, as well as leakage during transportation.

- They permit a higher payload when compared to drums stowed in dry containers (43 percent more volume).

- They can be handled mechanically, which results in cost savings, but also ensures safety when handling hazardous commodities (Morris 2007).

- They provide secure door-to-door multi-modal transportation (by road, rail, sea or inland waterways), and do not require specialized port-side infrastructure.

- They are safe and durable, with a design life of 20-30 years (Erera, Morales and Savelsbe 2005, Morris 2007).

- They can be cleaned and placed into alternate commodity service with minimum down-time.

- They can be used as temporary storage for customers with limited space or high-cost permanent storage. (Erera, Morales and Savelsbe 2005)

Further ISO tanks average an 18 to 20 percent savings over drums (Morris 2007).

Intermediate Bulk Containers (IBCs) are used for bulk transportation of liquid products. IBC containers are generally cubic in form and therefore can transport more material in the same area than cylindrically shaped containers ( Figure 2 ). IBCs are protected with a wrap around steel cage that provides greater protection of products stored in the large-capacity polyethylene container. IBC Tank has self-aligning stackable legs allow multiple IBC Totes to be stacked vertically.

Some IBCs have pallet-like frames with fork lift pockets to facilitate intermodal transportation. IBCs range in size and capacity and depending on the size of the container; it can weigh between 100 kgs and 1250 kgs. Transport regulation and pallet dimension standards in different countries can have an effect on the length and width of IBCs. If proven suitable, IBCs can be used for transport of dangerous goods and hazardous chemicals.

A major distinction between IBCs and tank containers is that IBCs are bought by the shipper and used or reused by the shipper’s own logistics department. While some large chemical producers also own or lease a fleet of tank containers, it is most common for the shipper to contract with ISO tank operator or logistics companies to buy a turnkey transportation service.

In the door-to-door bulk liquid transportation industry, the modern ISO stainless steel tank container reigns supreme in terms of safety, reliability, durability and environmental friendliness. Yet, depending on the cargo, tank containers are not always the lowest cost choice available to customers. (Caribbean Business, News Paper, 2003 ) IBCs have lower cost of ownership comparing to ISO Tanks and do not require heavy lift equipments for movements inside the warehouse.

Drums and barrels are used to transport small volumes. A wide range of liquid products can be transported in drums (Figure 3). Drums range in sizes and thicknesses with a choice of linings, configurations, and covers to transport materials for the chemical, paint and coatings, food, pharmaceutical and hazardous waste industries. Steel drums can weigh up to 220 Kgs. The main disadvantage of barrels and drums is that they are not really intermodal and requires manpower for changing transport modes.

Drums need to be secured are palletized in transit to avoid shifting and damages which could be more costly and time consuming. Drums are difficult to clean or it is expensive to clean them, the costs per transported liter or cubic meter are compared with tank containers higher, also bearing in mind that the production cost of barrels and IBCs are much lower. Another problem is one-way use of drums when chemicals are transported.

Because of environmental issues, used drums and barrels cannot be disposed easily. Depending on the residual cargo, cleaning and washing might be necessary before recycling. Steel drums get corroded very fast and not safe for reuse. The stainless steel tank withstands more impact and damages than steel and aluminum drums, but a lot more costly.

Given this background regarding ISO tanks and drums we move ahead to discuss the features of flexitanks.

Background of Flexitank

With the development of the container concept in the early 1970s, specialized containerships began to be built. The transfer of goods became much easier and safer and the use of containers paved the way for intermodal transport development (Konning 2005). Containerization has revolutionized cargo shipping and today approximately 90% of non-bulk cargo worldwide moves by containers. The problem with ISO tanks container is the logistics of empty tanks which bring about immense cost.

On a global level, the imbalances in container trades are a familiar and persistent problem. Large amounts of empty containers are being moved around the world. Drewry Shipping Consultants estimate the share of empty containers at sea as 21% of all containers transported. For land transport, the estimates are even higher (about 40%). The total costs to the industry of this inefficiency were estimated about 10 billion dollars in 2003 (Konning 2005). These are the costs of interzonal positioning (i.e. movements including a significant sea voyage). Including intrazonal positioning (i.e. movements overland) would add another 5 billion dollars (Konning 2005).

If we review the present strategies of shipping lines to control the costs of empty transport it is interesting to notice that these strategies are mainly focused on trying to avoid possible transport movements of empty containers, by improving the match of empty containers and cargo (Konings and Thijs 2001).

Flexitank are inflatable bags made of polyethylene that fits into a standard 20’ container converting it to a tank for transport of any Non-Hazardous Liquids. Flexitank can be loaded with a variety of non – hazardous liquids such as chemicals, wine, lubricants, additives, edible oils and many more.

“Flexible tanks…are bulk containers that are used for storing and transporting fluids. These tanks can be constructed from a variety of rubber or thermoplastic materials and typically have a capacity of up to 21000 litres. In use, flexitanks are used inside dry good containers, thereby converting such containers into bulk liquid containers capable of carrying up to 21.5 tonnes of non-hazardous liquid product.” (McClean 2000, 10)

The one-way disposable flexitank virtually eliminates the possibility of contamination and it can easily be disposed without causing any environmental issues. (Williams 2006)

Before being filled with cargo in packed in condition, empty flexi-tank itself weight approximately 100 kgs and will occupy about 250 litres, but in loaded condition can take up to 24,000 litres of liquid, depending on the specific gravity of the product. (Figure 4).

Flexitanks have been used for the carriage of bulk liquids for over twenty years. However, there has been unprecedented expansion since 2000 with the emergence of single-trip tanks. In the early years, shipments amounted to around 5,000 per annum. In 2006 the total global market had increased to about 120,000 flexitank movements (Williams 2006).

Annual growth of transportation in flexitanks is forecasted at between 15% and 20%. Of the present trade, it is estimated that between 15% and 20% of global loads emanate from South America, with the movement of wine and fruit juices being particularly prominent (CAO 2008). The flexitank market is divided between equipment suppliers and equipment operators. There are more than 40 manufacturers of flexitanks worldwide. There is presently no agreed standard regarding construction and operation. However, the Container Owners Association (COA) set up a flexitank working group with the inaugural meeting held in Paris on 28 June 2007. (CAO 2008)

Types of Flexitanks

Flexitanks are constructed in a number of different ways – single-layered and multi-layered – and from different materials, but typically polyethylene. (Carefully to Carry Committee 2007)

The first flexitanks were designed on the basis that they would be for multi-trip use. This meant that cleaning and repositioning costs were incurred. However, these costs have been eliminated with the single-trip flexitank, the type now most commonly in use (McClean 2000). The single-trip type now accounts for more than 95 percent of the global market (Carefully to Carry Committee 2007). The typical capacity of a flexitank is in the range of 10,000 to 24,000 litres.

The weight carried will depend upon the density of the commodity (McClean). The permitted gross weight of a container should never be exceeded, however, current practice is not to load more than 24,000 kg of liquid in a 30 metric tonne gross weight rated freight container, although even this is considered too high by some container operators (Carefully to Carry Committee).

A major difference between the designs of the two types of flexitanks is that a restraining harness is used in the majority of multi-trip ones. Harnesses were, and still are, deemed to be dangerous as they create concentrated pressure points on the tank surface which can result in premature material failure. The use of a restraining harness has been dispensed with in the case of single-trip flexitanks. If a flexitank is not filled to near its nominal capacity then a marked free surface effect and hydraulic surging of the liquid can occur, often resulting in damage to the container.

A flow meter should be used to ensure that a flexitank has been filled to its correct capacity (+/-500 litres of its nominal capacity). A visual inspection alone is unlikely to be sufficient (Carefully to Carry Committee 2007).

Use of Flexitanks

Flexibags are restricted to use with non-hazardous cargoes, mostly for chemicals, wine and edible oils and food products. Flexitanks or flexibags represent an attractive option when shipments are bound for less-developed areas that are either difficult to reach or ill-equipped to handle tank containers. The use of flexibags in such situations also eliminates repositioning costs. (Environmental Packaging Technology)

Flexitanks are gaining global market share as a practical and cost effective supply chain solution in the distribution of bulk liquid products, however there is some degree of scepticism amongst shippers. Despite all the economic advantages of flexitanks, ISO tanks containers are still the most used equipments in global transport of liquid products.

Safety Measures of Freight Containers

A discussion of the technical selection criteria of flexitanks are important because this information will help in comparing the marketing material in form of brochures distributed to customers and the industry practice to determine the gap in information provided. First consideration of cargo transportation is safety. One of the most important issues in container transportation is the safe loading of cargo into the containers, the containers being carried undamaged and finally the cargo arriving its final destination without any damages.

Because the possible damage that might occur in either one of these three steps might cause additional cost and labor or besides especially in case the containers carry chemical cargo, it might even cause sea pollution (Fernard 1996). Thus, in order not to damage the containers and the cargo loaded, there are certain technical considerations need to be taken care of.

Flexi-tank operators believe that a minimum 30 metric tonne gross weight rated container manufactured from Corten steel should be used, irrespective of the size of the flexitank. The actual sidewall strength is a function of a containers’ permitted payload, i.e. 0.6 x payloads (ISO 1496-1 Series 1 freight containers – specification and testing). Therefore, the sidewall panels of a 30 mt container will have been tested to a greater load bearing capability than, say, a 24 mt container. (Williams 2006, Carefully to Carry Committee 2007)

The side wall test requires a general freight container to be subjected to an internal loading uniformly distributed and arranged to allow free deflection of the side wall and its longitudinal members. The ISO Standard requires that, upon completion of the test, the container exhibits neither permanent deformation which will render it unsuitable for use, nor any abnormality which will render it unsuitable for use and that the dimensional requirements governing handling, securing and interchange shall be satisfied. Therefore, for a 30 mt container the test load will be of the order of 16.8 mt. However, a flexitank does not place a uniform loading over the full area of a sidewall and a gross liquid cargo weight of 24,000 kgs is the recommended maximum by some flexitank operators.

Containers are not specifically classified for the carriage of flexitanks. To minimise the stress upon the sidewalls of a freight container it is recommended that the height of the side of the flexitank in contact with the sidewall panel should be kept to a minimum. An optimum height of 1.3 metres has been suggested. It is also recommended by flexitank operators that the sidewall panels are fully corrugated from end-to-end and that a container with sidewall decal panels is not acceptable.

Few flexitank manufacturer/operator insists that container sidewall panels should be a minimum of 1.6 mm in thickness increasing to at least 2 mm at the extreme ends. Some flexitank operators recommend that only containers five years old or less should be used (CAO 2008). In the event that older containers have to be used then they must be in good condition. This means that no container should be used that already has signs of creasing or deformation to the sidewall panel corrugations and/or has had a partial replacement of a sidewall panel.

Some flexitank operators provide a standard practice checklist for container selection. If the container does not meet the criteria laid down the flexitank operators’ technical department request that they be notified (Carefully to Carry Committee 2007).

The information that is expected to be presented in the marketing material i.e. brochure or presentations of flexitanks should have the following information regarding the container’s installation:

- Functioning dual locking bars for each door panel;

- Left-hand door handles must have a hole to accept a safety bolt seal

- Door recesses for bulkhead fixings.

- Inspection of freight container prior to use

Irrespective of whether a single or multi-trip flexitank is being used, a freight container should be inspected to ensure the following:

- The container is structurally undamaged and free of sharp projections on internal side and end wall panels;

- The container is in a clean condition free from the residue of all previous cargoes;

- There are no floor imperfections:

- Floorboards and their retaining bolts are flush;

- There are no nails in the floor (nails/screws/fastenings should not be hammered into the floor);

- The underside of the container floor should also be inspected to ensure that no nails are protruding and all cross-members are in place and firmly affixed to the floor and the side rails and do not show signs of excessive deformation and/or cracking;

- Internal weld joints are smooth as rough weld joints can result in a flexitank being abraded (placing tape over the weld joints can provide extra protection);

- Cams on both doors position and lock correctly when the doors are closed;

- Handles position and lock fully in their hatches;

- Lashing fittings at bottom rails and corner posts should not be damaged as they could cause punctures; and

- Bolts affixing labels etc to the doors are not protruding through to inside of panels. If they are, they must be covered with foam or cardboard.

To prevent a loaded flexitank bulging outwards when the right-hand door is open, a false bulkhead is placed in the doorway. In the early years these bulkheads were of a solid timber construction. Plastic panels are now used, held in place with horizontal steel bars that fit into the vertical corrugation in the door pillars. (Figure 5)

To ensure that a flexitank does not bulge through the gaps in a steel framework bulkhead a sufficiently rigid sheet should be placed on the inside of the bulkhead. This prevents the flexitank chafing against the steelwork. (Carefully to Carry Committee 2007)

The stowage of flexitanks aboard a vessel needs to be considered in the context of two factors which may be conflicting. To reduce forces acting upon the container and the flexitank, stowage low down in the hold and near to the ship’s centre line is preferable. Such forces can be particularly high when the ship is partly loaded and/or has a large meta-centric height, resulting in a short rolling period. However, if the nature of the goods is such that they could solidify if they leaked (e.g. latex) and which could result in the ship’s hold bilge lines becoming blocked, then on deck stowage is preferable. (Carefully to Carry Committee 2007)

Ship operators may wish to consider whether, due to the nature of the goods, a leak could result in tainting of the hold space and/or other container loads stowed in the same hold. Accordingly, the information supplied by the shipper should include full details of the nature of the product and whether it could ‘solidify’, ‘taint’ or ‘damage’ the container in the event of a leakage. On balance, the optimum stowage for flexitanks is probably the first tier, on deck. (Carefully to Carry Committee 2007)

The above discussion facilitates in understanding the safety measures that should be taken in transporting fluids in flexitanks and other technical information regarding the make, material, damage of the tanks are provided. This information will be used to compare the brochure or marketing material for flexitanks used by a logistics company.

Apart from the technical considerations which concentrates on the safety of the cargo, there are financial considerations. The container choice is made by customers based on various factors. According to Tom Meulendyke, purchasing manager for packaging, third party, and transportation at Ashland Inc., Columbus, Ohio, “The choice is driven by economy – selecting the container that offers the lowest cost to the shipper, and the most efficient inventory management to the end customer” (Morris 2007).

Research Design

Methodology

Method

Flexitank is still a fairly new concept in transportation and their market share in contrast with other comparable equipments, such as tank containers and drums is insignificant. This exploratory study tries to enumerate how customer needs and individual or organizational barriers are affecting the demand for flexitanks. We undertake a qualitative research in order to identify the product and services deficiencies which are reducing the purchase of flexitanks by companies. The foundation of the study is based on feedback received from customers, operators and transport companies and secondary research.

Conducting questionnaire-based survey is an effective method to get primary information; nonetheless, for a qualitative market research it is necessary to conduct in-depth interviews with consumers and businesses to understand their opinions regarding the awareness of flexitanks, their access to the marketing material and the roll of educating the customers in adopting flexitanks (Frambach and Schillewaert 2002, Hurley and Hult 1998 ).

Due to confidentiality of business information, detailed quantitative information may not be obtainable and my data collection tends to produce general qualitative information. This paper will also discuss the process of decision making with a focus on the study of human behaviour causing change barriers and marketing problems.

Flexitanks in general are suitable for transporting non-hazardous liquid products; therefore our study has been narrowed down to a smaller group of consumers and transport companies shipping non-hazardous products which we can consider as potential customers.

In this study we try to ascertain the need to educate customers and how educating customers can influence the organizational buying process. The exploratory research tries to answer the questions that arise out of the study.

First, to find out the depth and scope of the information that is provided to the customers. This is done purely by secondary research of the available material of the flexi-tank usage that is given to customers.( e.g. brochures , catalogues , manuals ,etc.)

Second, the risk factors that is associated with the usage of flexitanks. This is critically examined through secondary research by studying the safety instructions provided to the customers along with the published interviews of flexi-tank makers and brochures published to describe the product. Then we compare this finding with the information provided to the existing customers and try to find out if there is a gap in the information provided and the actual deficiencies or hazards in the product.

Third part of the research tries to analyse the views and perceptions of potential customers and see where are the shortcomings or possibility of influencing them to switch to use flexitanks instead of substitutes. This part is done through telephonic interviews with the purchasing managers of organizations who use other containers and not flexitanks. The telephonic interviews also reveal the potential causes which act as a barrier to the acceptance of flexitanks by these organizations. This leads us to the fourth part of our analysis where we try to ascertain the role of education and training in increasing market acceptability of flexitanks.

This analysis will help to identify the gaps in the training and educational initiatives in marketing of flexitanks. This is done purely with the help of secondary research of information available through magazines and company published materials. The fifth part of the research handles the cost efficiency of flexitanks vis-à-vis other forms of containers like ISO tanks, IBCs or drums. This will provide an understanding into the advantages and the selling points of flexitanks.

The information regarding the cost is derived from secondary materials and is compared to the qualitative data collected through the questionnaire survey. The study concentrates on the operation of alternative equipments available in the market to discover the advantages of flexitanks in-terms of cost, product, space usage and disposability are analysed. This is done in order to identify possible sources of resistance for choosing flexitanks. This study will also cover the analysis of the existing marketing barriers to develop strategies for improving user-acceptance.

The objectives have been segregated in order to divide the report into two parts: the secondary and the primary research part. B2B marketing research has to be based on secondary as well as primary research due to the involvement of product technicalities which gain prominence (Reeder, Reeder and Brierty 1991). For our research purpose we use secondary data from journals, magazines and newspapers and collect relevant information regarding the information that are provided during marketing a flexi-tank to organizations, the risk factors associated with cargo transportation in flexitanks and the technical problems associated with it. In the primary research we do a questionnaire based survey.

We analyse the survey data with the help of descriptive statistics. We try to ascertain which product related issue could be influencing the quality perception of the customer. The survey tries to ascertain the survey related issue is the bottleneck for customers’ non-adoption of flexi-tank. And we do a comparison with the ISO tank to understand the relative pros and cons of flexi-tank.

Data Collection

Sample

The primary data had been collected by two methods: survey questionnaires and telephonic interviews. The sample was chosen a method of convenience sampling (Freedman, Pisani and Purves 1998). A larger group of companies have been selected for interviews in different industries such as chemical companies, liquid food industries, freight forwarders, container operators and port authorities. The data has been collected from companies both with and without experience in flexitank operations. The sample was divided into two groups: first the existing users of flexitanks and second, the non-users of flexitanks. The survey questionnaire was sent to all. From the first set of the sample, 7 organizations responded. No responses were received from the non-users of the flexitanks, for whom we conducted a telephonic interview based on a structured questionnaire.

Survey

The survey questionnaires consisted of both open-ended as well as close end questions. The responses regarding the product have been taken in 5-point Likert scale. The questions were directed to ask the potential problems that customers face while using flexitanks. For the data analysis purpose we use descriptive tools like graphs and mean of rating scores to determine the average rating of the reasons which are the primary reasons which stand as barriers to sale of the product.

The mean scores were derived by quantitatively coding the qualitative responses. The Likert scale responses were provided in as ‘strongly agree’, ‘agree’, ‘neutral’, ‘disagree’ and ‘strongly disagree’. The responses were codified as 5 for ‘strongly agree’ and 1 for ‘strongly disagree’. The mean scores were then derived by averaging the score of the responses for a particular question.

The closed-end questions were designed to ask questions regarding the product, service and customer perception regarding the product. The open-end questions asked for customer suggestions and their opinion about the product. The former will help us obtain organizational perception (Hayes 1997, Webster and Wind 1972). The questions are used and applied on an organizational innovation adoption model (Frambach and Schillewaert 2002) which helps to ascertain how adoption of the product has undergone and how they adopt the product for the first time. The later will help us obtain the individual perception of the purchaser of the product. The analysis has been done through the use of descriptive statistics.

The survey questionnaire was sent to the companies which are users as well as non-users of flexitanks. The responses that we received from the users of flexitanks were 7 and that from the non users was also 5 in number.

Data Analysis

The first part of the data analysis deals with the analysis of the marketing brochure of flexitank as used and doing a gap identification analysis of the published material for marketing of flexitanks and the actual technical information required to be delivered which would make the communication more complete. This is a qualitative analysis done with the aid of promotional material and the technical information we have gathered through our literature review. Here we codify the information provided in a marketing presentation of flexi-tank into the following categories of information provided:

- Product introduction

- Stowage instructions

- Loading Instructions

- Discharging instructions

- Safety Measures

- Compatible Products

- Pricing

- Order Procedures

The second part of the research involves in identification of the marketing flaws of flexitanks and finding the suggestions by analyzing the survey data. The method employed for data analysis is a purely descriptive method using graphs. The ratings on the Likert scale were averaged to find the average ratings and then the mean averages were ranked in ascending order to find the most relevant important factors that affect the usability of flexitanks by the existing users of flexitanks.

The data was analyzed using descriptive tools in Excel. Then the reasons as presented by the users and non-users of flexitanks are compared, which gives an idea as to what additional marketing effort needs to be employed to increase adoption of flexi-tank among non-users. Further a comparative study of the information provided in the marketing material and that of the material that the users and non-users actually receive.

The data analysis aiming to understand the three research questions i.e.

- What is the customers’ perception regarding flexitanks? Are there any gap in the customer perception and the information provided in product brochures?

- What are the commercial barriers to acceptance of flexitanks by freight forwarders or manufacturers’ of liquids?

- How helpful will be educating the customers in marketing the products?

The first research question which directly relates to the customer perception regarding flexitanks and the marketing barriers which are responsible for non-adoption of flexitanks by freight forwarders has been analyzed through the analysis of the survey data. The perception of the customers are identified through the analysis of question 7 of the questionnaire sent to the users of flexitanks. For the non-users we analyse the question which directly asks the customers regarding their concern regarding flexitanks (See Appendix). Further in order to understand the existing gap in the perception of customers and the information provided through the product brochures are analysed by comparing the perceptions regarding flexitanks with that of the information provided in the brochure.

The second question tries to identify the barriers which cause the non-adoption of flexitanks. This part is analysed through the questionnaire survey of the non-users of flexitanks. Analysis of the survey on non-users shows why they are unwilling to accept the product. This would provide the barriers that the present marketing techniques used for flexi-tank impose on the non-adoption of the product. The third question identifies reasons why educating the customers regarding the product is useful to the marketers and how education can influence adoption of the product. This question has been answered with the help of the literature review and the survey.

The data collected from the primary as well as secondary sources are therefore, analysed in the next section. The analysis is primarily qualitative in nature.

Marketing Material Analysis

Advertising materials have long been valuable objects of analysis for linguistics as data for disclosing some feature either of the language or for studies on the language of advertising itself (Sobhie 2003). The buying decision-making process in informal communication networks is characterized by interaction of many participants or groups with alternative solutions for buying in an organization.

The communication as described in the literature describing organizational buying process is important for our study, as it will help us find the importance of marketing literature, promotional material, and training of clients in developing a network of communication. These are essentially dependent on the marketing and selling process of industrial products. So in marketing flexitanks this process has to be utilized. Contributing to this effort, in this section we focus on the interaction between a flexitank operator and its corporate customers in their advertising brochures describing the stages in which this interaction unfolds in these materials and the strategies used by the company to offers its products and services.

The marketing materials that we have analysed are product presentation of the flexi-tank by companies. For the purpose of research we research the marketing presentation of four freight forwarders (UTB 2007, Schenker 2007, Philton 2007, PER Logistics 2007). A generalized summary of our findings are presented below.

On analysing the flexitanks operator brochure, we consider each topic and see their occurrence in each brochure. This procedure yields 6 elements which are demonstrated in the brochures which are further divided into 15 elements. For example, “Information regarding flexitanks” is divided into information about “what is flexitanks’, its “advantages and disadvantages”, “flexi-tank operator branding”, “product comparison with other products”, and “the kind of products that can be transported in flexitanks”.

We codified the availability of the element in the brochure as ‘yes’ and non-occurrence as “no”. As table 1 shows, for instance, if ‘cost comparison of flexitanks with other types of containers’ is depicted in the brochure of the operator then it is considered “yes” which is quantified as 1, while quantifying. Otherwise it becomes “No” and fetches a 0. Following this we see that all the operators in the sample provide information regarding flexitanks, which includes “what are flexitanks” and the name and logo of the operator.

75 percent of the brochures present information regarding the “the kind of products that can be transported in flexitanks”, “Risk and prevention while loading”, and “Advantages and Disadvantages of Flexitanks”. 50 percent of the brochures include information on “Cost effectiveness of flexitanks”, “Installation information”, “Risk and prevention while unloading”, and “Product comparison with other containers”. The brochures fail to mention information regarding the risk related issues with flexi-tank.

Table 1: Brochure codification.

On doing a detailed study of the marketing material for flexitanks, we see that there is no product introduction which may actually introduce the product as a novel concept to the customers which would initiate the adoption process. Detailed information provided in the presentations regarding the precautionary measures to be taken while installing flexitanks. But they fail to provide information regarding the safety measures while transporting the product in trucks or vessels. Further there is limited information regarding the process to be followed while discharging of the cargo. Clearly the presentation provides extensive information to the customer regarding the tank’s technicalities. The presentations provide the following to persuade the buying influencers:

- All the service providers give information regarding –

- Installation procedure with pictures detailing the procedures

- Loading procedure

- Some of the presentations provide information regarding-

- The tank, its make, and the cargos it can safely transport.

- A comparison of the cost to the customer of transporting their cargo in flexitanks in comparison with other available containers like ISO tanks, IBC, drums, etc.

- Risks associated with loading and/or unloading flexitanks

- Disposal information

The missing areas which should have been included in the promotional presentation or brochure are the risk related issues of flexitanks such as “Risks and prevention in-transit”, “Risk and prevention of contamination”, Risk and prevention of spillage”, etc. The first areas of concern are regarding the unavailability of information regarding risk associated with flexitanks and the procedure of disposal of containers. Cost comparisons of substitute carriers are also not available (UTB 2007, Schenker 2007) except for in a few presentations (PER Logistics 2007, Philton 2007).

Further no product introduction has been provided and the pricing of the product is missing. The presentations does not mention the insurance that will be provided or not provided due to spillage or loss of product or in case of contamination or damage of the product. The manuals and brochures do not provide any information regarding risk factors associated with flexitanks.

For ensuring that the product is adopted by the customers, it is quintessential to persuade and influence the buying decision-makers and to pass on the effective information regarding flexitanks to the decision making team. In case of container selection, purchase managers act as gatekeepers to the decision-making group. The most important concerns for the purchasing manger are cost of the product and quality which includes safety of transportation of the liquid bulk.

Hence it is extremely important to provide a cost comparison of flexitanks vis-a-vis ISO tanks and drums in order to demonstrate the effectiveness of using the container. Further, properly illustrated demonstration of the loading and unloading process should be presented in order to provide a clear picture of the process.

Survey

Users of Flexitanks

We do the analysis taking question by question. The first question was concerned how long the respondent had used flexitanks. The responses gave the following figure. As we see in figure 5, 42 percent of the respondents said that they were using flexitanks for more than 1 year. 14 percent of the respondents said that they used flexitanks less than 6 months and another 14 percent said that they never used flexitanks. 28 percent of the respondents used flexitanks for more than 3 years.

The response to the industry the respondents belonged showed that 57 percent of the respondents transported non-hazardous chemical and the remaining 29 percent transported food products (liquid) industry an 14 percent transported oil in flexitanks. This demonstrates that all the respondents belonged to industries which dealt in liquid products.

Of the respondents who answered the survey, 57 percent said that they have used both ISO tanks as well as flexitanks. Figure 6 shows that only 14 percent of the respondents said that they were using flexi-tank, but they switched to ISO tanks, 14 percent switched to using flexitanks from ISO tanks, and rest 14 percent never used ISO tanks.

All the respondents believed that the flexitanks were more suited for the transportation of liquid cargo. This reconfirms the answer to question which asked which product the respondents transported in flexitanks and it clearly indicates that for transportation of liquid non-hazardous products, the respondents feel that flexitanks are the best way of transportation.

When the respondents were asked which type of container is safer for non-hazardous liquids, maximum number of the respondents answered that it was flexitanks. Figure 7 show that 86 percent respondents believe that flexitanks are the best option for transportation of non-hazardous liquid and rest 14 percent vote for ISO tanks.

Then we investigated into the industries where flexitank was being used. Our survey result is demonstrated in figure 8. Chemical, food products and transportation and logistics industry frequently use flexitanks.

Size of the organization is important to understand so that we can know which organizations we need to target. Further, the size of the organization also affects the buying decision in the company. Research has shown a prominent effect of the size of the firm determined by the number of employees in the firm (Crow and Lindquist 1985). Figure 9 shows the size of organizations that have used flexitanks.

The question asked if the tank had been used by organizations which have employee strength of 0-10, 10-20, 20-50, 50-100, more than 100. We clubbed the ranges as small (for 0-10 and 10-20 employees), medium (for 20-50 and 50-100), and big (for organizations with more than 100 employees). As figure 9 shows, 72 percent of the respondents belong to big and medium sized companies. So this is the organization size we should target for our research.

The next set of questions was asked to ascertain the quality of service or product and product related aspect which may have become the barrier to adoption or non-adoption of flexitanks.

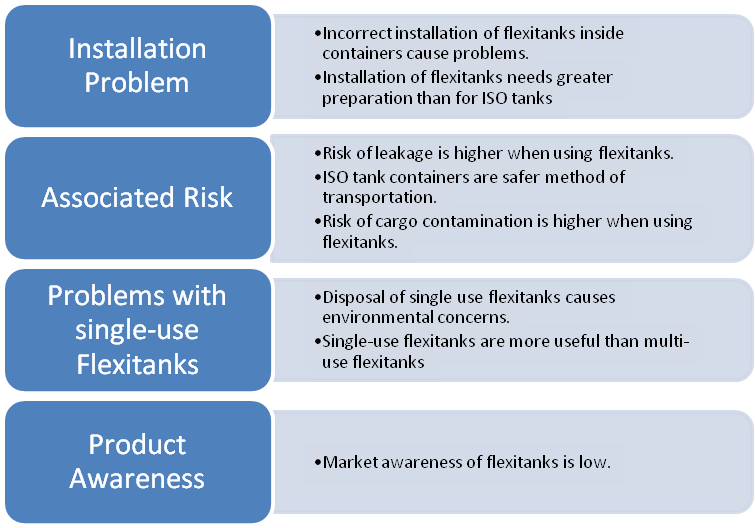

We cluster the related questions 20 into 11 groups. The groups that we derive are as follows: Installation Problem, Associated Risk, Problems with single-use Flexitanks, Product Awareness, Selection Problem, Service Quality, Accessibility, High Cost, Multi-Use tanks, Product Fault, and Loading unloading Problem. The mean scores for these groups are derived from the mean of the rating averages of the questions (see Appendix A). For instance mean score of problems with leaky hose, problems with leaky/cracking bulb heads and problems with doors of flexi-tank which do not close properly. After grouping the questions into 11 heads (as mentioned above) we derive the following table (Table 1).

Table 2.

Table 1 represents the average score of the grouped reasons. All scores above 3 are formatted in green. They depict an ascent on the part of the respondents regarding the persistent problems in flexi-tank usage. This show all the groups except for loading and unloading problems pose a major problem in usage of flexitanks. Now if we want to consider the problems which need immediate attention are the ones whose rating averages are 4 or above, which implies that the problems of flexi-tank in these areas are more problematic. This is represented in figure 10. So the primary problems with the product as viewed by the respondents who have used the product are as follows:

- Leakage problem

- Contamination problem

- Installation problems

- Disposal of flexitanks

- Low market awareness.

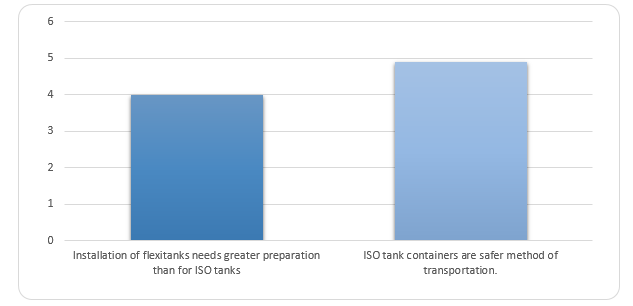

When we compare flexitanks and ISO tanks from the point of view from users of flexi-tank we find that the problems that are highlighted the most are that of safety and installation (see figure 11). Clearly the users of flexi-tank believe that the main advantages of using ISO tanks over flexitanks are the ease of installation of the former and that they are a safer mode of transportation.

Interview of Non-Users and Survey

The interviews were conducted over the telephone. There were the organizations that did not use flexitanks. The responses when summarized showed the following result:

- Almost everyone in the company heard about them, but no one has ever seen one. This implies that there was knowledge but full awareness regarding the product was lacking.

- They considered flexitanks as “big plastic bags” and did not know anything regarding the loading and discharging operations.

- The problem regarding flexitank that comes first to their knowledge is regarding safety issues.

- They believe that spillage of cargo can be a major issue.

- They have limited information about the cost and not sure if the system has cost benefits.

- They had questions regarding the disposal of empty single use tanks and if they were recyclable.

- They requested for a catalogue or brochure of the product which shows that they lack awareness regarding the product. This means that there was need to market and advertise the product more to these companies.

- They know that ISO tank containers are more expensive than flexitank and the reason for this (as they perceive) is because they are safer and there is more demand for the tanks.

- They questioned about the regular cargo insurance would insure the cargo in flexitanks.

- They feel that it is a new product and they have not yet tested it.

Table 3: Summary of Interview.

The interview summary brings out the fact that the non users of flexitank lack awareness. Due to which their perception regarding the product’s viability and safety measures are affected. Table 3 shows that the non-users of flexitank are not aware of the product (they have just heard about it). They do not have access to proper material which could persuade them to adopt the technology as proper marketing material helps in the adoption process of a new product (Frambach and Schillewaert 2002).

There is marked reluctance on the part of the organizations to adopt flexitanks, as they do not seem interested to use flexitanks even when they are aware that flexitanks are cheaper than ISO tanks. The reason, as revealed by the interview, is perceived safety issues. This perception can be substantially reduced by proper marketing of flexitanks through educating of the prospective clients (Gaillard-Meer 1984).

Now analyzing the survey data of the non-users of flexitanks facilitates in determining the areas which should be included in the marketing material. A questionnaire survey was conducted of non-users of flexitanks in order to understand the perception of the customers regarding the product, their awareness of the product and the product related information that should be included in marketing brochure or presentation.

In analyzing the non-users responses we consider organizations which have been in the logistics business for 5-10 years or more years. 60 percent of the respondents were from company which was present in the industry for 5-10 years. Rest belonged to companies which were more than 10 years old. 60 percent of the respondents had used ISO tanks priorly. All the respondents had priorly used drums to transport their goods instead of ISO-tanks.

The non-users of flexitanks had considered the use of flexitanks instead of ISO tanks. 60 percent of these non-users had received marketing material for flexitanks.

The information which is most prized and wanted regarding flexible containers are compatible products, stowage instructions and discharging instructions. The marketing brochure we discussed had all the rated four features in the marketing material for flexitanks.

Table 4: Ranking of Marketing Information.

60 percent of the non-users of flexitanks believe that flexitanks are the cheapest means of transportation for transporting non-hazardous chemicals. This is a significant number which indicates that the non-users are aware of pros and cons of the fluid transport via flexitanks.

Almost 60 percent of non-users of flexitanks believe that the safety is a primary reason for not using flexitanks and lack of trained staff. Among the non-users, 80 percent of the employees belong to the transport industry.

Cost Comparison

The cost comparison is based on the quantitative data derived from secondary sources. The cost using flexi-tank compared to other modes of intermodal container transportation, viz. ISO tanks and drums is less (Kukdong 2008). We do a comparison of the cost of using Flexitanks, ISO tanks, IBC and Drums to see if flexi-tank is cost effective for transporting 100,000 litres of liquid. We consider manpower required for setting up the tanks for bulk transportation. This is done by comparing the manpower required in man hours. This man hour calculation is inclusive of hours to prepare, handle, fill and load into containers. The cost comparison is done for 23000 litres flexi-tank, 1000 litres IBC, and 200 litres Drums. The cost comparison is shown in figure 12.

The figure shows that the cost of using flexitanks is less than that of IBC, ISO tanks and drums to transport the same quantity of liquid. Further if we compare the space utilization statistics for the tanks (see table 5), we see that the time cost too is lower for stuffing and filling of flexitanks as compared to other modes of transportation. The total cost of using flexitanks for 100.00 litres of liquid is 70 percent less than IBCs, 65 percent less than drums, and 24 percent less than ISO tanks.