Supply chain management involves the tactical synchronization of the supply operations and strategies that encompass these business operations in a certain firm to enhance the long-lasting efficiency of the firm and the supply chain.

It includes enhancing goods, process and supply chain functions. A supply chain wide system is one that incorporates decision making at all levels of the chain. It provides a perspective of production, service and information flow.

Companies need to adopt this approach because it is incorporated with business-wide operations. This system processes data into a user-friendly format hence easing the decision-making process.

It deals with daily operations and assists in a smooth planning process and decision making by managers in the chain. The system also has mechanisms for making projections and coming up with alternatives (Chopra, & Meindl, 2013).

The supply chain-wide system has the abilities to harmonize information transversely in the supply chain to ensure the flow of information to the chain stakeholders. This ensures reciprocated achievement for all in the chain.

It is known that information needed by firms is usually not within the firm; hence this system is imperative as it ensures e-commerce whereby orders can be handled. Information and communication technology has made this possible.

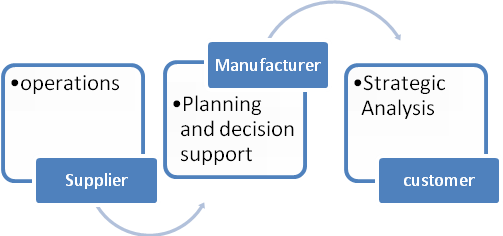

Firms such as IBM that have gone on board and used this system hence can demonstrate how this system works in ensuring the flow of information. The diagram below demonstrates the free flow of information (Chopra, & Meindl, 2013).

Cycle inventory is a technique of checking stock by doing inventory count-up regularly. This is inventory that is scheduled to be produced or bought in huge batches than demanded by clients. Cycle inventory is used to leverage the economies of scale in a supply chain.

Cycle stock inventory is significant as it makes part of a business asset. It forms the stock inventory that can be sold and restocked devoid of safety stock. It also saves costs on transportation and warehousing.

Safety stock is important in every company because it is not easy to predict future demand by consumers. Safety stock is used to meet excess demand that goes beyond the expected demand for a specified time.

A high level of safety inventory avails a greater quantity of products and enhances improvement in consumer satisfaction. This also leads to a rise in average stock and hence leading to a rise in the asset base of the company.

This is mostly used in technology companies where the value of their stock can become obsolete. For instance, the worth of computers can decrease substantially if not sold on time (Graves & Willems, n.d.).

Taking advantage of economies of scale is very important in the supply chain as this reduces costs. Shipping is a substantial factor in fixed cost. Shipping together diverse goods for different orders reduces batch size.

A case in point is where one pick-up can make deliveries to many clients at the same time without making unnecessary trips.

IBM is a good illustration of a company that employs supply chain-wide technology. This has made it possible for IBM to integrate their stakeholders in their supply chain.

Use of this system has led to a reduction in their transacting expense by removing barriers to supply of their products to the market.

They also have advanced customer service by interacting with all the players in the supply chain. Their market segment has also increased significantly hence gaining a competitive advantage over their competitors (Butner, 2007).

References

Butner, K. (2007). Blue print for supply chain visibility. IBM Institute for Business Value. Web.

Chopra, S., & Meindl, P. (2013). Supply Chain Management (5th ed.). Upper Saddle River, NJ: Pearson Education International.

Graves, S., & Willems, S. (n.d.). Strategic Safety Stock Placement in Supply Chains. Web.

McAdam, R. (2000). Knowledge Management as a Catalyst for Innovation within Organizations: A Qualitative Study. Knowledge and Process Management, 7(4), 233-241.