Wild Dog Coffee Company is a business which aims at upholding the highest standards of quality and providing the best possible service to customers. One of the iconic beverages served by the store is the cappuccino which is enjoyed by numerous customers every day. In order to ensure that new employees have a clear understanding of how to achieve consistent results with making cappuccino, the company developed guidelines describing the steps for this process.

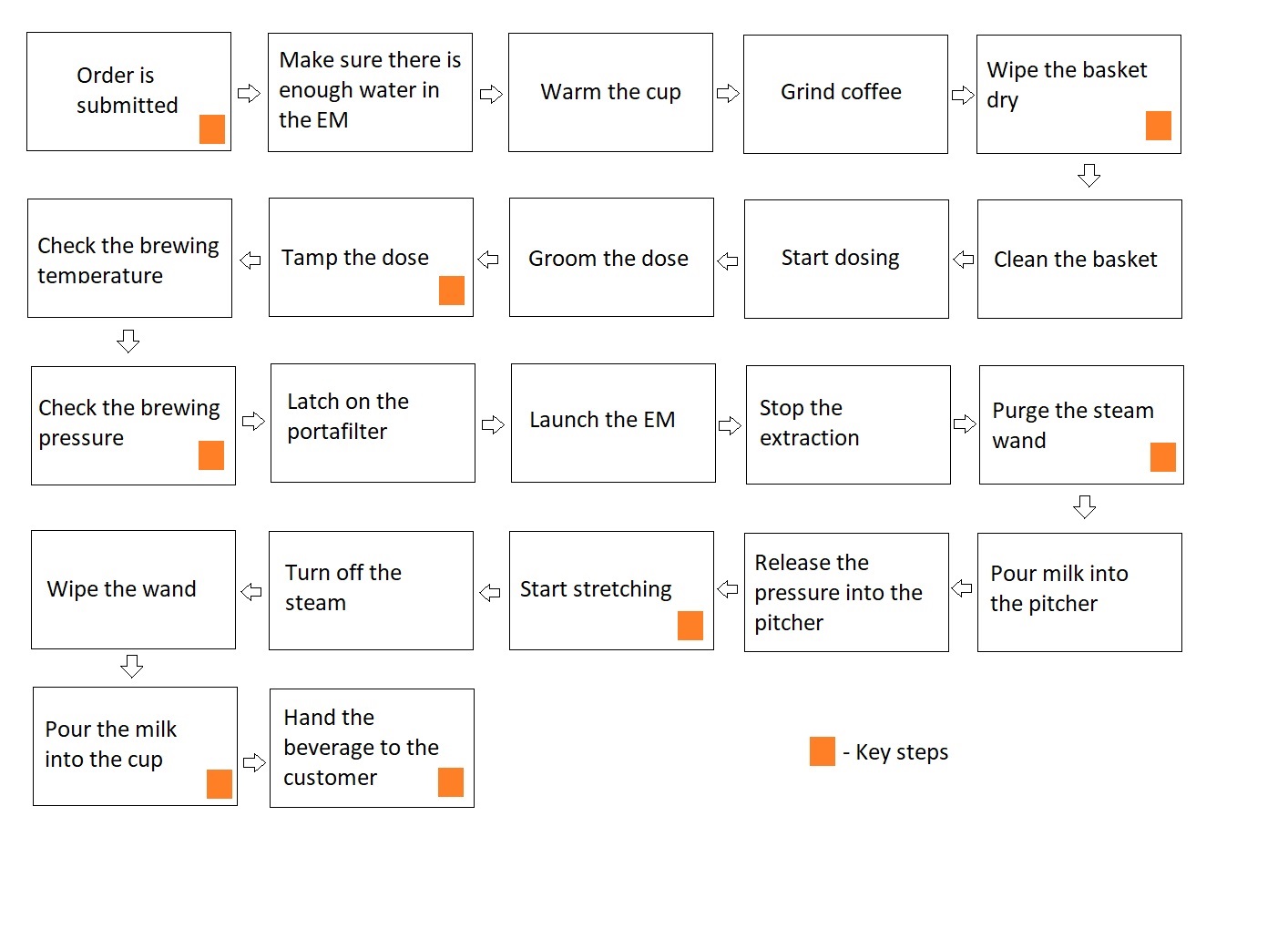

The first step is the customer submitting their order for a cup of cappuccino. Such a step is important because any beverage at Wild Dog Coffee Company is made only after the client asks for it. Employees must not make espresso in advance and then simply pour it into a cup (Appendix A). The next step involves checking whether the espresso machine has enough water in its reservoir and whether it is fresh. Lack of liquid or any contamination will negatively impact the quality of the beverage. Then the barista must warm the cup in which cappuccino will be poured later to maintain a proper temperature level.

Then the barista has to use the grinder to produce fine particles for the future cappuccino. The step is essential for the proper preparation of the beverage since the size of particles considerably affects the taste of espresso, and large or coarse ones will negatively affect the taste of the drink by making it sour. The next stage involves taking a portafilter and cleaning the basket inside it in order to remove any excess moisture since it can worsen the beverage’s quality (Appendix A). Then the barista has to check the basket and make sure that none of its holes are congested. Such a procedure is vital because clogged holes in a basket may stop water from being distributed evenly across the coffee bed. The barista then must start dosing to ensure that the grounds fill up the basked of the portafilter as evenly as possible. If one side of the basket receives more grounds than the other one, it once again will worsen the quality of the final product.

Once dosing is finished, the barista has to groom the dose by removing the extra grounds from the coffee bed if the dose is too big. Grooming is important for ensuring that the grounds are distributed evenly in the basket and especially on its top. Then the barista has to proceed to the tamping phase of the process in order to lock in distribution and polish the surface of the coffee placed in the basket (Appendix A). The procedure is essential since it helps prevent void spaces from being formed in the coffee bed and presents the barista with information on the actual size of the dose. Then the barista must check the brewing temperature and adjust it if it is not correct. The temperature is vital because it ultimately influences the taste of the final product and therefore has to be precise to achieve the desired outcome. Similarly, the barista should check the brewing pressure and ensure that it is at an appropriate level since high pressure can make the taste of the beverage bitter.

The next step requires the barista to latch on the portafilter to the espresso machine and launch the pump to start the brewing process. Stop the extraction process after a designated period of time of thirty seconds. Stopping the process earlier may lead to a sour taste of the beverage, while prolonging the operation may add bitterness to it (Appendix A). Then, the barista has to prepare the milk for the cappuccino, and the first stage here involves purging the steam wand of excess water by puffing it into a towel. This way, even distribution of the steam will be achieved. Then, the barista must pour milk into a pitcher.

The next step concerns putting the steam wand’s tip into milk and releasing the full pressure. The steam wand must be opened to its maximum since this helps achieve the necessary level of creaminess for a cappuccino. Then, the barista should start stretching or frothing the milk, which is essential for the beverage (Appendix A). The next stage is turning off the steam wand and removing the pitcher when the desired effects are achieved. After steaming is finished, the barista has to wipe the wand and purge it. Finally, the barista must pour the milk into the cup with the espresso while maintaining the texture of the beverage. Once the preparation of the cappuccino is finished, the barista has to hand the beverage to the customer and receive payment for the order.

The Procedure Documenting the Steps of the Process

There are several metrics which will be used for assessing the performance of the aforementioned process. The first one is the weight of the dose of the coffee in the basket of the portafilter after tamping. Since Wild Dog Coffee Company serves only double shots of espresso, in this case, the metric will equal 18 grams of ground coffee in the basket. The weight of the dose can be measured using a kitchen scale. Another essential metric which will help track the performance of the process is the weight of the espresso after the extraction. The target metric here will be 60 grams of the beverage, which also can be measured with the kitchen scale. Yet, it is also important to measure the time in which the 60 grams of the drink will be produced.

Essentially, the metric here is 30 seconds, and the barista will have to track it with a stopwatch. Thus, it can be treated as a two-part metric, namely 60 grams of espresso in 30 seconds. If the machine produces 60 grams of espresso in 25 or in more than 30 seconds, then it will negatively affect the taste. The solution here will be to choose a finer grind if it is too fast and a coarser one if it is too slow. Finally, the beverage delivery time at Wild Dog Coffee Company must equal two or three minutes. The time can be once again measured with the help of a stopwatch.

Procedure

In the first section, all steps essential for the process were identified, and their importance was assessed, thus allowing the reader to understand the value and utility of all parts of the cappuccino-making. The procedure section, which can be found in Appendix B, will expand on each step in more detail. It will describe the actions which the barista will have to perform during each step.

Purpose

The purpose of the procedure described above is to create a product which will have excellent quality and will be enjoyed by the clients of Wild Dog Coffee Company. It is clear that the process of espresso and even cappuccino-making is extremely difficult and subject to various factors which can affect it. As a result, the taste of the beverage may fluctuate depending, for example, on who prepares it and in which way. Thus, the process presented above serves as a document which aims at assisting employees with making the beverage and achieving consistent results with it. Thus, the purpose of the procedure is to both deliver a great product and ensure that the impact of external factors on it is minimized.

Analysis of Data for Process Changes

Every enterprise, when assessing the effectiveness of their processes, needs to implement statistical tools which will help them analyze the existing data and, based on the results, introduce changes. The process capability index helps determine whether a certain procedure can be performed within certain limits. In the case of Wild Dog Coffee Company, the business has to focus on ensuring that all orders are finished on time. Thus, by relying on the data presented in the Beverage Service Times table, it is possible to discover whether the business will be able to maintain delivery time at 2-3 minutes.

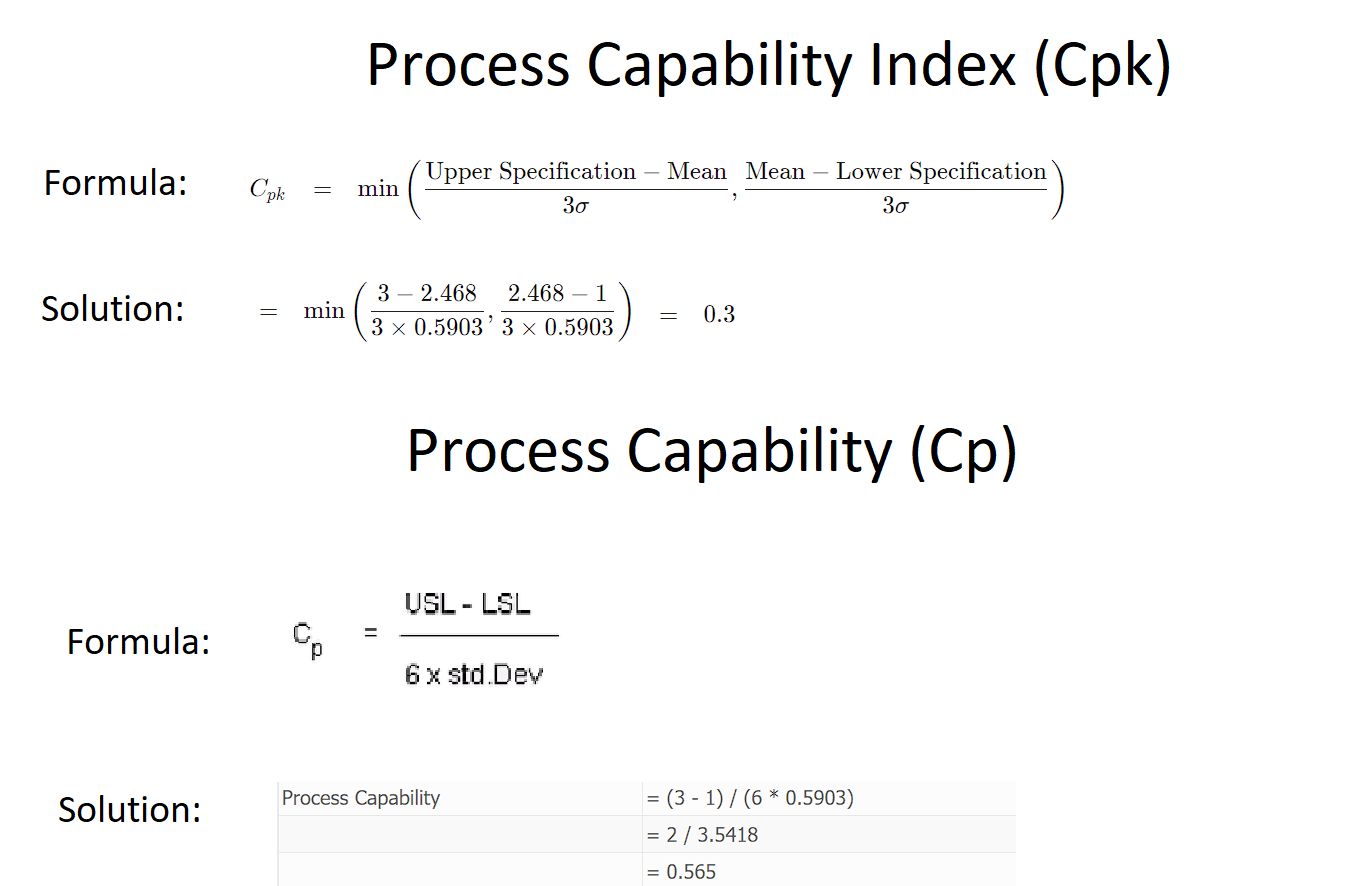

In order to determine whether the aforementioned process is centered and capable at 3-sigma, it is necessary to choose the appropriate variables first. The first variable will be the Upper Specification Limit (UL) which will equal 3 since it is the maximum number of minutes in which the beverage should be delivered according to the senior barista. The next variable is the Lower Specification Limit (LSL) which will equal 1 because it is the minimum time required for making and delivering a beverage (Appendix C). Then, the formula used for the analysis will need the Process Standard deviation, which has already been calculated and equals 0.5903. in this case. Finally, the last essential variable is the process means which has been calculated by adding up all of the values of 50 beverage preparation events and then dividing their sum by their total number. As a result, the mean variable was found to be 2.468.

Thus, in order to determine whether the process is centered, one has to calculate its process capability. Based on the variables presented above, the process capability (Cp) equals 0.565 while the process capability index (Cpk) equals 0.3 (Appendix C). In order to consider a process-centered, the CP has to be a least 1, and ideally 1.33 to ensure that it is perfectly centered (Holweg et al., 2018). In the case of the process in question, it cannot be considered centered since its value is only 0.565.

Based on the results of the analysis, it is also possible to identify whether the process is capable at 3-sigma. A process can be considered to be capable at 3-sigma if its CPK value equals 1 (Patel, 2017). Once again, the Cpk value of the process in question does not meet the criterion and is only 0.565, which is insufficient (Appendix C). Therefore, the analyzed process is found to be incapable at 3-sigma and has to be changed.

Finally, using the available data, one can also discover whether the process is in statistical control by combining the information on several components which are depicted in the chart (Appendix D). The variable reflects delivery times of the 50 beverage preparation events, and it is compared to the mean, the USL, and the LSL. The chart demonstrates that the process is not in statistical control because there is a substantial variation across beverage preparation events in terms of the delivery time. Moreover, on thirteen occasions, the delivery time surpassed the Upper Specification Limit but also was below the two minutes mark. Such evidence indicates that there are factors which are ultimately responsible for the lack of consistent performance of the process. Thus, there is a necessity to determine which factors negatively impact the process and cause delays in the delivery times and to find ways to minimize their impact to achieve the desire results.

Analysis of the Cause and Effect of Process Variances

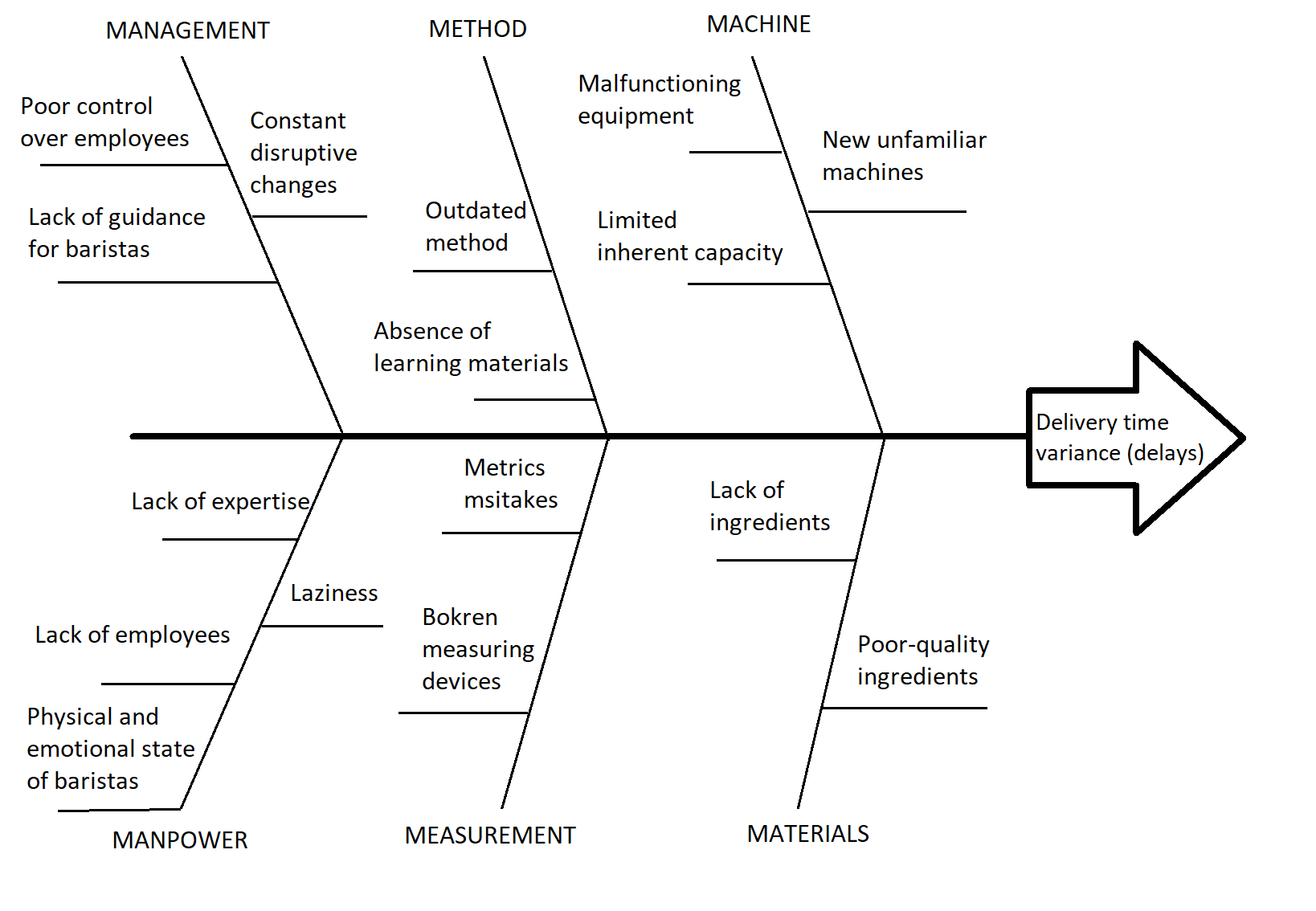

- In order to determine all the important factors causing the aforementioned variation related to the process, it is important to identify the segments which may include the sources of variance. All “6 Ms” are relevant for the process of espresso beverage preparation; therefore, each of them will be analyzed separately (Appendix E). The first one is management, and the main cause of the variance in this segment is the poor control over the employees. Essentially, the person in charge of the coffee shop may function as an actor who motivates the workers to perform better, and as a result, they tend to produce coffee in a faster manner. As a result, the absence of the managing staff enables baristas to work less efficiently. Additionally, the management may also involve the lack of proper guidance on the part of the supervisors can cause some baristas to be unable to make the right actions required in certain situations (Appendix E). Finally, the factor of change in the standard procedures in the company may also be considered a cause of the process variance because it may disrupt the established workflow.

- The next segment is the manpower, and it is the most important one for the process in question since the barista is the main actor responsible for the delivery time of the order. First of all, baristas can lack proper training and experience in the sphere of espresso-making, and subsequently, their performance may vary depending on a particular beverage (Appendix E). For instance, milk-steaming techniques for cappuccino and latte are not only complex but also different, and a barista must learn to perform them quickly. It is clear that a person has to practice for a considerable period of time to achieve consistency in their work. Moreover, another cause belonging to the manpower segment is the lack of personnel. Essentially, Wild Dog Coffee Company is a small business but also an extremely popular one.

- Nevertheless, the management cannot afford hiring more people sine the influx of clients varies each day. Subsequently, on certain occasions, the baristas simply cannot make the beverage in under three minutes because there are too many people waiting in line. Another cause of variance is employees’ emotional and physical state which can fluctuate depending on a number of factors (Appendix E). For example, baristas can feel exhausted after working for a long time, and their performance may gradually decrease by the end of their shift. Similarly, on certain occasions, baristas may be depressed, which also can negatively impact their ability to work efficiently and in a fast manner. Finally, employees may also simply be lazy and not deliver beverages on time if there is no one around to monitor their performance.

- The next segment concerns the method related to the process, and the most apparent cause here is the lack of clear and effective instructions for making beverages. Thus, baristas, especially new employees, may not have the knowledge and skills to prepare some types of espresso efficiently since they simply do not have any learning materials. Additionally, the company may provide an outdated method of preparing espresso beverages to its employees, and, as a result, it may take more time for baristas to make certain drinks (Appendix E). The next segment is the measurement, and the main cause here is related to the training materials. Essentially, baristas may be given the wrong metrics to measure the quality of their performance. For example, an instruction for making a cappuccino may contain a mistake in the brewing temperature degrees. By relying on this metric, the barista may spoil the beverage and will have to start the process again, thus delaying the delivery time. Moreover, measuring devices such as scale and thermometer may be broken, which can prevent baristas from correctly assessing their performance.

- The machine is also a vital segment which contains a variety of potential causes of the substantial variance in the delivery time. The first one is the malfunctioning espresso machine or other types of devices such as the grinder (Appendix E). Wild Dog Coffee Company may not conduct consistent checks of the equipment, and at times the espresso machine may not work properly. As a result, baristas will fail to deliver the order in under three minutes because they will have to solve the issue with the equipment first. Another possible problem related to the machines is their inherent capacity.

- For instance, the grinder may not be able to grind coffee beans quickly because it is cheap and limited by design. Subsequently, the grinding process may take a lot of time and cause the barista to waste several seconds. Nevertheless, new equipment also can cause issues to emerge, which can contribute to the decrease in the performance of employees. For example, a new espresso machine may have a completely different design, and a barista who has never worked with it may struggle with making beverages using it.

- Finally, the materials segment can also negatively impact the delivery times, and one of the sources here is the poor quality of coffee. The main ingredient for any espresso is coffee beans, and if they are stored inappropriately or ground in advance, they will lose their qualities. Subsequently, the barista will have to go and get another pack of beans which also takes several minutes, eventually affecting the order delivery time. Similarly, milk can become sour, and the barista will have to get a fresh one. There can also be problems with water, and the barista will have to pour more of it into the espresso machine. Thus, the lack of materials and the need to replenish them can significantly impact the delivery times.

Quality and Customer Service Improvements

Based on the analysis presented above, it is clear that Wild Dog Coffee Company has a problem with the delivery times of its orders. Thus, there are several methods the business can use to reduce the time it takes its employees to prepare a beverage. As noted earlier, the Cpk value of the process in question shows that it is not capable at 3-sigma. To solve this issue, the company has to introduce proper training for its employees to ensure that everyone is able to prepare beverages in under three seconds. Essentially, all baristas working at Wild Dog Coffee Company must meet certain criteria, and the most important of them should be the ability to deliver the order in a fast manner. Additionally, the workers must be motivated to perform well, and the company has to introduce incentives for preparing espresso in under three minutes. The management can offer bonuses to everyone who manages to avoid any delays with the orders. Thus, baristas will have a good source of motivation to strive to achieve a high level of efficiency and performance.

Nevertheless, there are many factors which can slow down the delivery process which do not depend on the actions of the employees. One of them is the equipment, which has to be new and be kept in check in order to ensure that it does not break runs smoothly. Moreover, the company has to update its equipment annually since it is impossible to avoid wear-and-tear when the equipment is working almost no-stop throughout the year. Similarly, the grinder also has to be new and fast in order to decrease the amount of time spent on the procedure of grinding. The next factor which does not depend wholly on the employees is the materials and their quality. The management at the company has to monitor and ensure that the grinder always has new coffee beans, the espresso machine is full of water, and the milk is fresh. Thus, baristas will save a lot of time which otherwise can be spent on the actions related to the replenishment or replacement of the materials.

Additionally, the management must provide the employees with proper training and track their progress to ensure that everyone is able to serve a beverage in less than three minutes. Learning materials documenting procedures for each drink have to be given to workers so that they could access them at any moment and check whether they are performing the right actions. Finally, the management must hire only those baristas who are capable of learning new methods of coffee-making and are ready to continuously improve their performance and enhance their skills.

References

Holweg, M., Davies, J., De Meyer, A., Lawson, B., & Schmenner, R. (2018). Process theory: The principles of operations management. Oxford University Press.

Patel, S. (2017). The tactical guide to six sigma implementation. Taylor & Francis.

Appendix A

Flowchart

Appendix B

Procedure

When the order is submitted, the barista must tell the customer the approximate time in which their beverage will be ready. Then, the barista has to turn to the espresso machine and check whether it has water in it by opening the reservoir. During this step, it is important to ensure that the water is fresh. The next step is warming the cup, which can be done by placing it on the drip tray grill of the espresso machine and pouring hot water into it. Then, the barista will have to use the grinder to produce a dose of coffee for the espresso. At this stage, the barista has to choose the fine grind setting on the machine since it is the only appropriate option for espresso.

While the grinder is working, the barista should wipe the portafilter’s basket and make sure that it is dry using a towel. Additionally, the barista should check whether all basket’s holes are clear and not congested by taking it out of the portafilter and inspecting it carefully. Then, the barista has to start dosing by placing the portafilter with the basket near the tip of the grinder and releasing the coffee grounds. Here, it is important to dose the right amount; namely, the weight of the basket before grooming and tamping can be approximately 20 grams. During the next stage, the barista will have to grow the dose to ensure that the coffee grounds are spread evenly in the basket. The grooming can be performed by pushing the mound of grounds using a finger towards one edge of the basket and then to the opposite one, thus achieving an even distribution of the coffee.

After the grooming phase, the barista has to tamp the coffee bed in order to compact the coffee grounds into the basket and remove any voids filled with air. Tamping is performed using a tamper, a tool with a flat face made of steel, and fitting the basket. The barista must place the tamper on top of the basket and press it slightly enough to eliminate void spaces and achieve a perfectly level tamp. Then, the barista must check the water temperature and adjust it to be around 195-205°F (90-96°C). While checking the brewing temperature, the barista has to flush water from the boiler in order to remove coffee particles stuck to the dispersion screen and remove the overheated water. Thus, the appropriate temperature will be established, and the barista can measure it with a thermometer.

Then, the barista must check the brewing pressure and set it to 8-9 bar, it is also important to remember that the pressure may fluctuate, so the barista has to monitor it consistently. During the next stage, the portafilter has to be latched onto the espresso machine by placing it against the dispersion screen and turning it to the side. Next, the barista should launch the EM, thus starting the extraction process. Then, the extraction process must be stopped after 30 seconds, and the weight of the finished product must equal approximately 60 grams. Once the extraction is finished, the barista has to start preparing milk. Here, they should flush the steam wand by pressing the “release” button. Then, the barista must pour cold milk into the pitcher, and the amount should be enough for the beverage at hand, not more or less. The next stage is extremely important, and it involves releasing the steam into the pitcher. Here, the barista must place the tip of the steam wand slightly below the surface of the milk and release the steam.

Once the pressure is released, the barista must start stretching immediately to achieve the desired froth. In the case of cappuccino, stretching is performed by lowering the cup while the level of the pitcher’s content is increasing. It is important to continue keeping the tip of the steam wand slightly below the surface of the milk (froth). Then, the barista must turn off the steam, yet only when the temperature of the milk reaches approximately 150-160°F (65-70°C). Once the froth is ready, the barista must once again flush the steam wand and wipe it using a clean towel, removing milk from it. The next step is pouring the frothed milk into the espresso cup. The pouring should be performed at a controlled rate in order to keep the crema and avoid milk separation. Once the cappuccino is ready, it can be served to the customer by placing it on their table.

Appendix C

Appendix D

Appendix E