Introduction

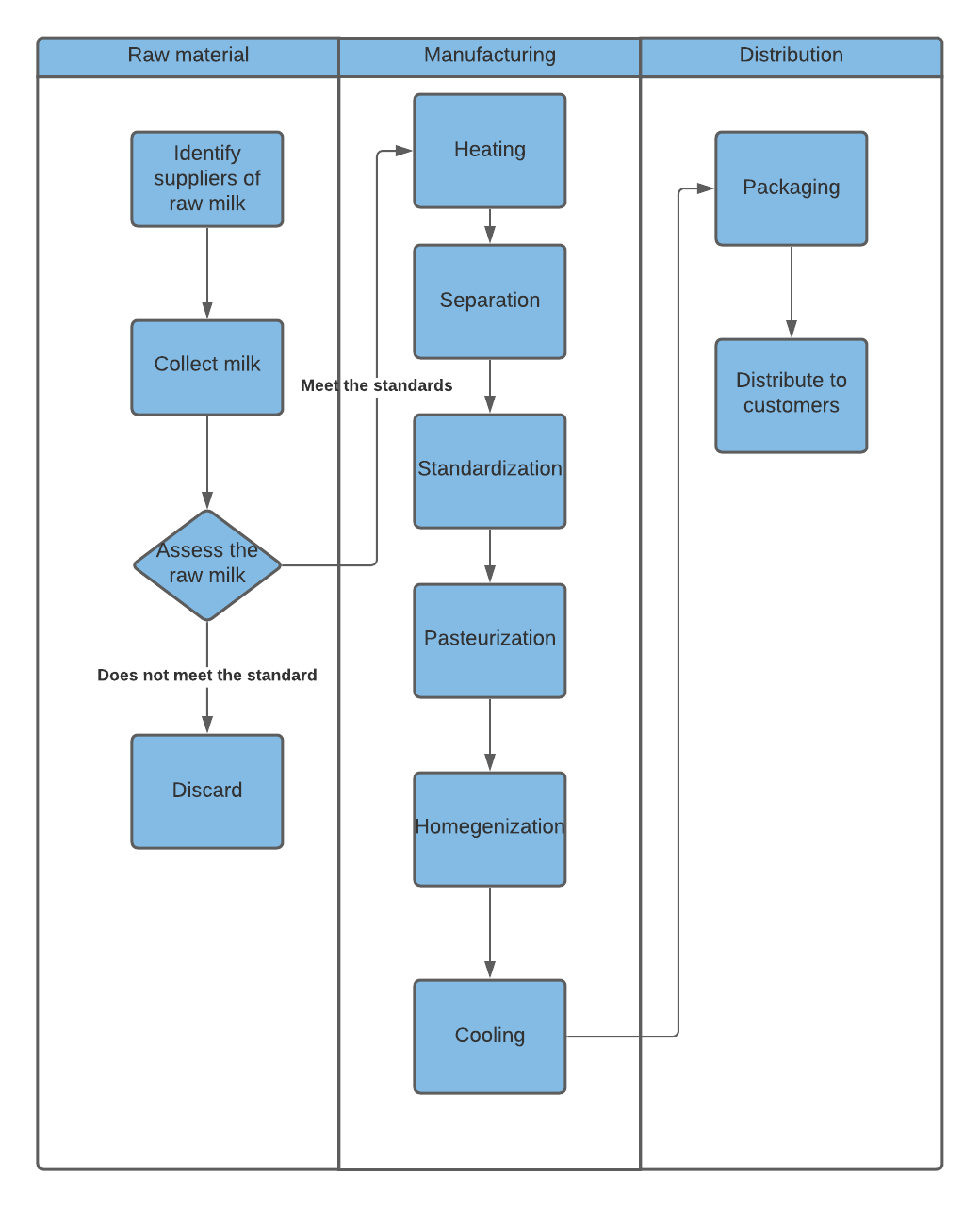

Al- Juneidy dairy is the leading factory for the production of dairy and food products in Palestine. One of the leading dairy products being produced by the company is fresh milk (“Al Juneidi Dairy,” 2021). At the factory, the process begins with collecting raw milk from farmers and suppliers around the region. Next, the milk is accessed to determine its quality before being passed to the next stage of production (“Al Juneidi Dairy,” 2021). The raw milk is passed through a process, which involves heating, separation, skimming, standardization, pasteurization, homogenization, and cooling. The milk is packed in bottles of 500ml, 1 liter, 2 liters, and many more for distribution to the market. The following is the process used for the production of fresh milk at Al- Juneidy dairy factory.

Analysis of the Flow Chart

Drawing from the chart above, fresh milk production is grouped into a collection of raw milk, manufacturing, and distribution. The main role of the process is to add value to the raw milk collected (“Al Juneidi Dairy,” 2021). The process is focused on making sure that the fresh milk sold after the production process is safe for consumption. This explains why the company ensures that the raw milk obtained from suppliers is effectively accessed to determine its suitability for consumption (“Al Juneidi Dairy,” 2021). Raw milk deemed unsafe for consumption is discarded, while the one deemed safe goes through the entire process.

Recommendations for Improvement Opportunities

The first area of improvement is the need to make customers the center of the process. Customers are always in charge of deciding on the desired product outcome (Heizer et al., 2017). They are more likely to participate in co-production and shared decision-making on the “whats” and “hows” of the production process with the provider when they play the co-creator role (Vogelsang et al., 2018). According to time-function mapping, the notion is to begin with customers and understand the production process (Heizer et al., 2017). The factory should start with collecting customer requirements prior to commencing the production process. The requirements from customers should dictate the production process. For example, the quantity of fresh milk being products should align with the customer demand. Therefore, customers play a significant role in the production process.

The second area of improvement is the adoption of process control. Process control involves using technology to verify and control a physical operation. It is also used to identify and control pressure, temperature, and quantity (Heizer et al., 2017). Based on this, process control is supposed to be added in a flow chart to indicate that the process is being controlled automatically. The use of process control is integral in ensuring that the end product meets the set quality by eliminating any form of error (Heizer et al., 2017). As a result, Al- Juneidy dairy factory should strive to integrate it into the system. As the leading company in dairy and food products production, process control assist creates trust in customers.

Conclusion

Despite the fact that Al- Juneidy dairy factory is the leading company in dairy and food products, there is a need to improve the process. First, the company’s production process omits customers, who are key stakeholders in the production process. Thus, there is a need to factor in customers because they help in decision-making. Second, there is a need for the company to introduce process control techniques in the production process to assist in adding value to the end product. So, the two improvements are crucial in making sure the outcome meets the set standards.

References

Al Juneidi Dairy & Food Products Co. (2021). Contact Out. Web.

Heizer, J., Render, B., Munson, C., & Sachan, A. (2017). Operations management: Sustainability and supply chain management (12th ed.). Pearson.

Vogelsang, K., Liere-Netheler, K., Packmohr, S., & Hoppe, U. (2018). Success factors for fostering a digital transformation in manufacturing companies. Journal of Enterprise Transformation, 8(1-2), 121-142.