Abstract

The present research is dedicated to the investigation of the concept of benchmarking in the UK manufacturing sector on the example of Diageo plc, a beverage producing company occupying an outstanding, stable place in the UK beverage manufacturing market. The hypothesis of the work includes the assumption that the BM techniques of Diageo may be significantly improved with the help of integrating several most commonly used BM models with the purpose of eradicating all drawbacks thereof and strengthening their positive characteristics. By means of theoretical research five modes such as SCOR, BPR, six sigma lean management, EFQM, DMAIC and PDCA have been chosen and integrated into one innovative BM technique that proved to be more efficient and over-grasping in the context of analyzing all aspects of the company’s functioning as reviewed by the BM research.

The main conclusions as which we arrived in the course of our BM analysis of Diageo plc suggest certain gaps in BM analysis that has been previously applied in the company. With the application of the innovative integrated BM model such characteristics as customer and supplier satisfaction, standardization of BM metrics have been researched at a new angle and with a higher level of efficiency. Further work suggested in the sphere includes more attention to ecological benchmarks adopted in the BM scheme of Diageo plc and movement towards open innovation as an alternative way of BM and continuous quality improvement.

Key words: supply chain, supply chain management, benchmarking, BM models, SCOR, BPR, six sigma, DMAIC, PDCA, EFQM, BM indicators, quality improvement.

Figures

- Supply Chain Flows…….

- Publications on BM by chronological order………..

- Number of Publications on BM………

- The Share of Each Subject Field in Overall Research on BM…………..

- Evolution of Approaches in BM……….

- BM Process Objective…..

- The BM Wheel………

- Distribution of Types of BM in the UK……….

- Risk and Reward Variables for BM……….

- Customer Satisfaction BM Indicators…….

- Employee Satisfaction BM Indicators……..

- Supplier Satisfaction BM Indicators…………..

- The Arrangement of the SCOR Model…….

- Reasons for not Implementing Six Sigma by Respondents…

- The Deming Cycle……….

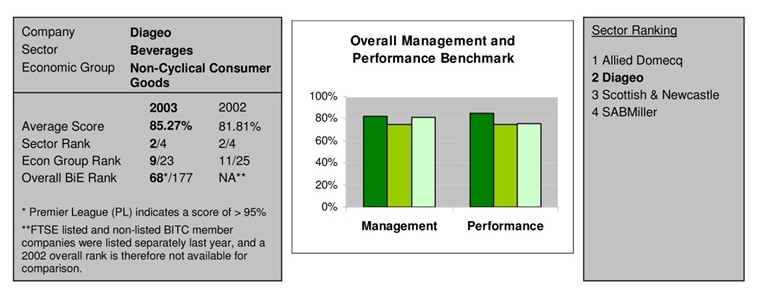

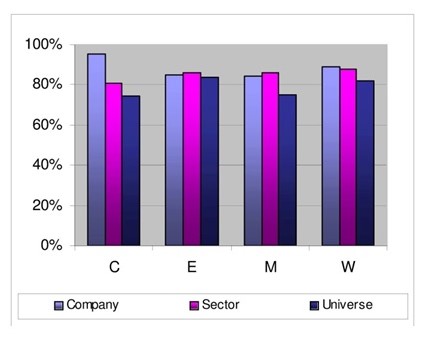

- Overall Management and Performance Benchmark….

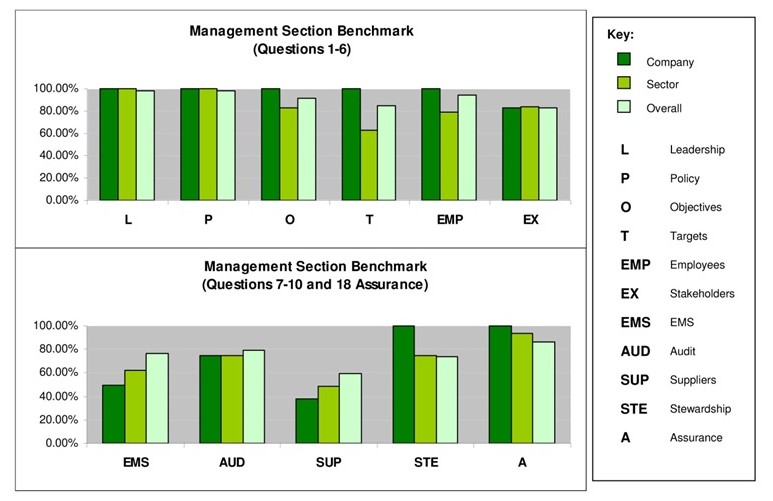

- Management Section Benchmark….

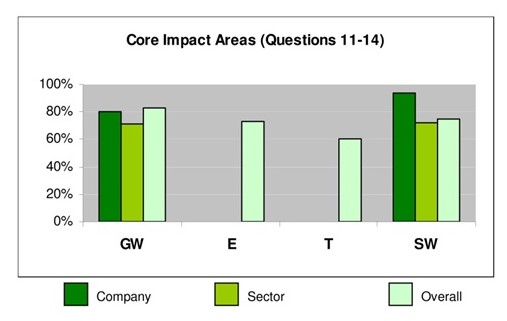

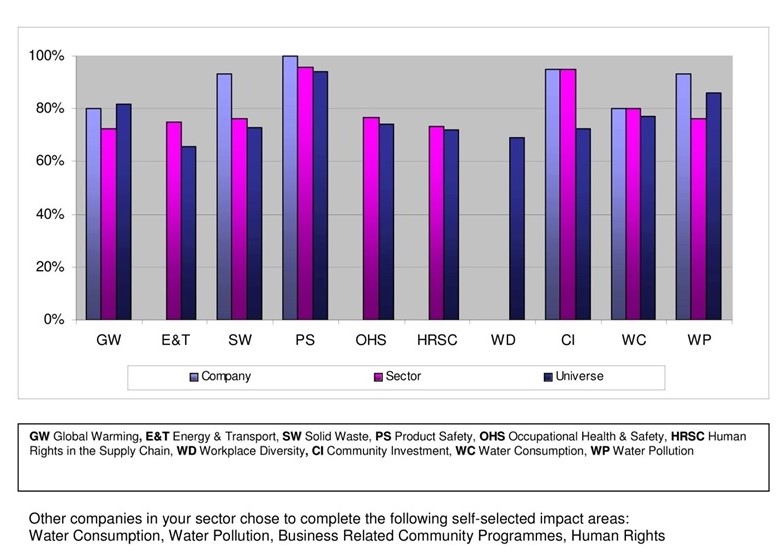

- Care Impact Areas…

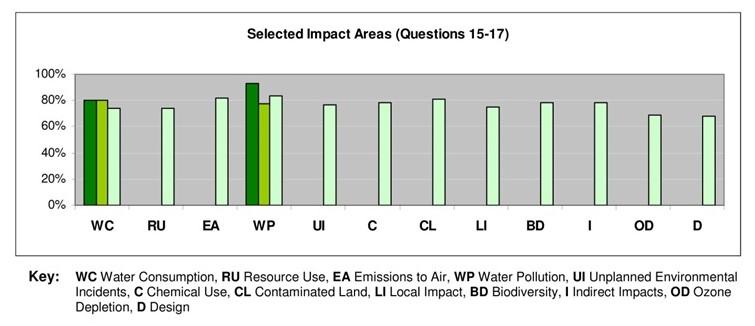

- Selected Impact Areas…..

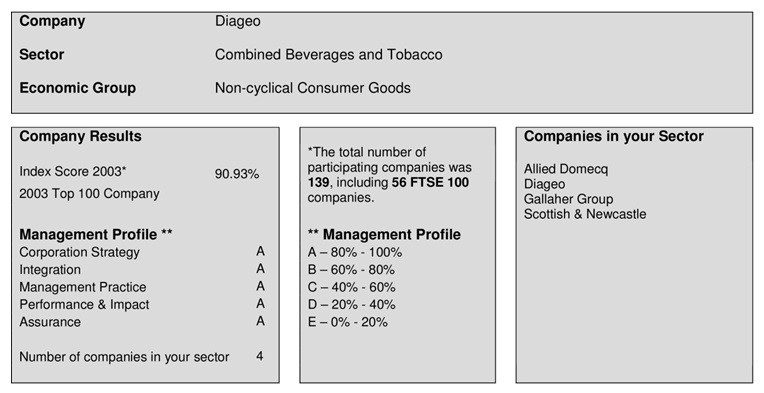

- Company Results on Corporate Responsibility…

- Overall Corporate Responsibility Summary…

- Diageo Corporate Strategy Benchmark….

- Diageo Integration Benchmark….

- Management Practice Diageo Benchmark…

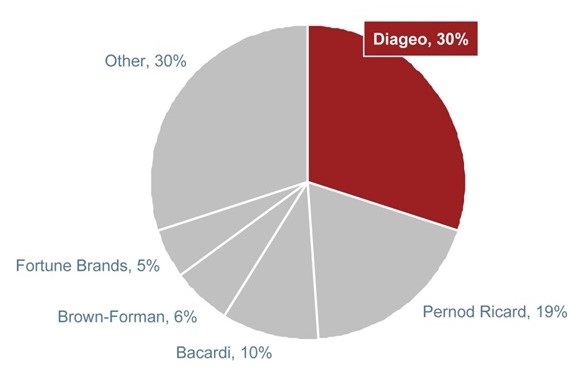

- Diageo Performance and Impact Benchmark….

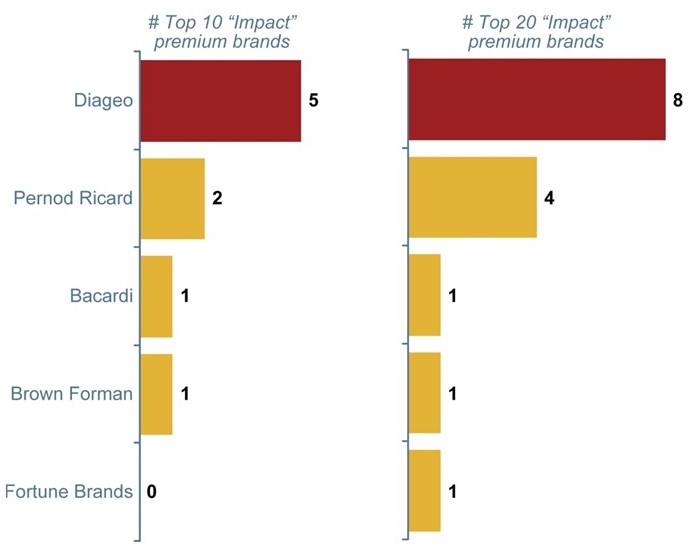

- Distribution of Diageo Brands in the World Market….

- Market Share of Diageo…

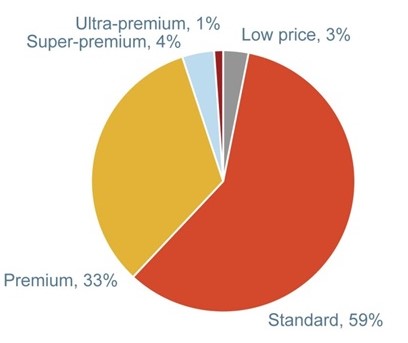

- Pricing Strategies of Diageo…

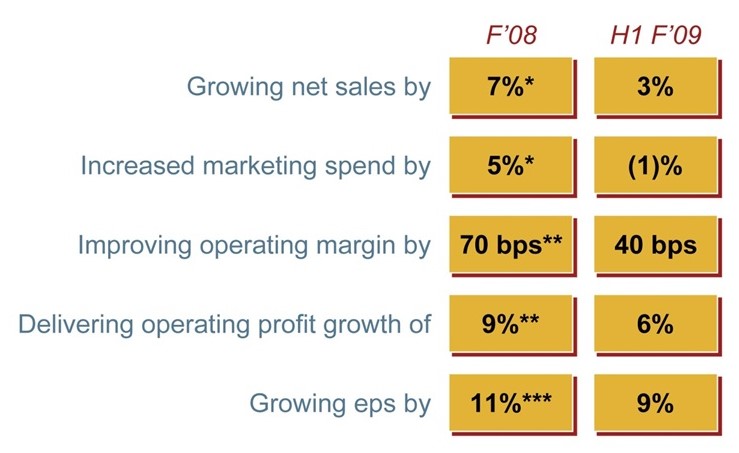

- Key Performance Measures of Diageo…

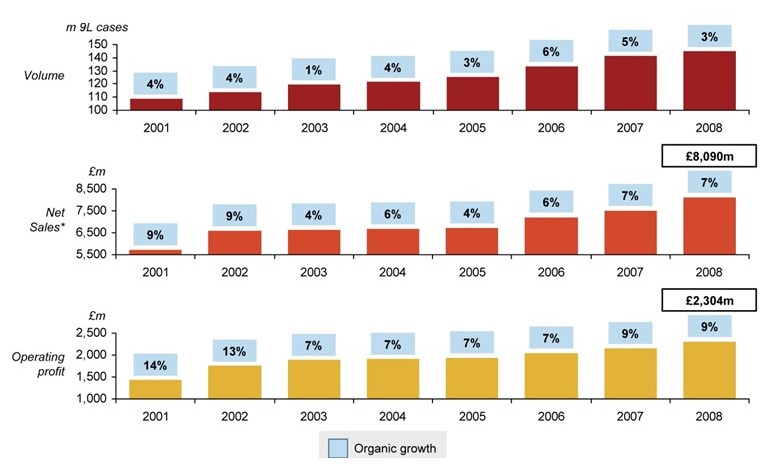

- Delivery Measures of Diageo….

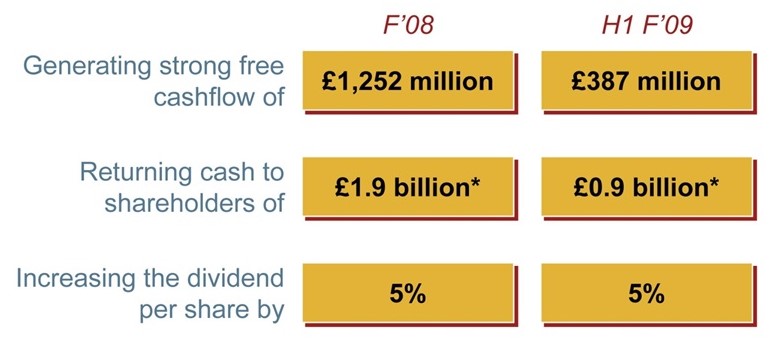

- Cash Flow Measures of Diageo….

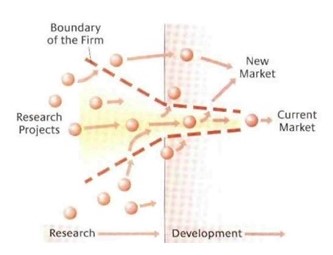

- Open Innovation Process………

Abbreviations

- APQC = American Productivity and Quality Center

- BM = Benchmarking

- BP = Business Process

- BPR = Business Process Reengineering

- CBI = Confederation of Business Industry

- DMAIC = Define Measure Analyze Improve Control

- DTI = Department of Trade and Industry

- EFQM = European Foundation Quality Model

- HPW = High Performance Work

- MPC = Material Planning and Control System

- PDCA = Plan Do Check Act

- PROBE = PROmoting Business Excellence

- R&D = Research and Development

- RONA = Return on Net Assets

- SC = Supply Chain

- SCM = Supply Chain Management

- SCOR = Supply Chain Operations Reference

- TQM = Total Quality Management

- UKBI = United Kingdom Benchmark Index

Introduction

Background of the Research

The UK manufacturing sector used to be the major source of export, national output and employment, counting for 40% of the overall UK economy after World War II. Nowadays it still remains a powerful segment of national economy, by employing about 4 million people and further 2.4 million people being highly depending on the manufacturing sector while being employed in the sphere of service industry (The Facts about UK Manufacturing, 2002).

At the present moment, the role of manufacturing sector in the UK economy is also estimated at a high level – it comprises 20% of national economy and brings revenues at a size of £150 billion a year. It is responsible for 60% of the country’s exports, thus constituting a more than perceivable contribution to the international trade. However, it is notable that within the past half a century the importance of the manufacturing sector began to shrink considerably: at the end of 1970s the sector employed about a third of the UK population, while comparison with the present time shows the loss of more than 150,000 working places in the sphere of manufacturing just in one year time period (The Facts about UK Manufacturing, 2002).

The most competitive areas of the UK manufacturing sector are aerospace, high technology and pharmaceutical industries. The UK is also strong in food, beverages and tobacco production (The Facts about UK Manufacturing, 2002). Nevertheless, the recent tendency that is clearly observed within the scope of the UK economy and admitted by a set of specialists is the gradual overshadowing of the manufacturing sector by service industries taking the lead in the national economy (Kollewe, 2008). Gradual reduction of importance of the manufacturing sector is called de-industrialization, which actually takes place in the UK at the present moment. About 20 percent of the manufacturing sector’s output in the UK might decline before overcoming this recession (Riley, 2009).

Despite the unpromising tendencies observed for the manufacturing sector, it is still evident that the country will seize to sustain stability of economy and profitability of national and international trade without a well-organized manufacturing sector, even if it stops to occupy the leading position in the overall UK economy. The leading manufacturing companies constantly struggle for the improvement of their production capacities, facilitation of their logistics and supply chain organization in order to sustain competitive advantage, implement ongoing innovation and improvement and remain profitable in the national and international market. Supply chain arrangement has gone a long way of recognition as one of the key elements of arrangement of the working process, now being paid tribute as a strategic element of the company’s activities arrangement. Thus, the supply chain of a manufacturing company has been recently paid more attention to with the purpose of enhancement of not only the manufacturing process itself, but in the optimization of overall activities of the company to achieve higher productivity at lower costs, which has always been the chief aim of any enterprise entering the market.

Hence, it is clear that continuous, deep research should be undertaken in the sphere of the supply chain arrangement in order to enable manufacturing companies to assess the current position of their strategic planning activities and enable them to introduce sufficient changes and promote improvement this way. With the help of innovative benchmarking techniques this process becomes possible, as well as the adequate assessment of potential of the company together with a set of practical guidelines for improvement may be worked out by the described means.

In order to work out a set of practical guidelines in the sphere of benchmarking of a UK manufacturing company and to illustrate the integrated benchmarking model designed for a more efficient way of analyzing economic activities in the manufacturing sector Diageo plc has been chosen as a leading representative of the UK whisky manufacturing industry. Diageo plc is one of the leading beverage manufacturing companies in the UK and in the world as well, possessing a set of such famous brands as Baileys, Smirnoff, Captain Morgan or Johnnie Walker are produced by Diageo plc (An Introduction to Diageo, 2009). By applying the unified and improved benchmarking model in the process of the company’s consideration we want to prove that benchmarking is first of all an essential element of the economic analysis and, secondly, want to show all pros and cons of benchmarking models that existed before thus enhancing understanding of necessity of benchmarking.

Purpose of the Study

The purpose of the present study is to concentrate on the supply chain organization process in the manufacturing sector of the UK, namely in Diageo plc as a representative of the sector of beverages and spirits production, and assess its strengths and pitfalls with a further emphasis on the way to eliminate the drawbacks and facilitate the development of advantages of its functioning. The assessment and analysis tool chosen is benchmarking, which will allow the creation of a unified and clear idea of the current state of affairs in the supply chain arrangement and will enable the researchers to conduct analytical benchmarking comparison with other representatives of the manufacturing sector and find a set of solutions for improvement.

Research Problems

The range of problems stipulated for the present research lies within the scope of the supply chain channel arrangement in the manufacturing sector of the UK economy, namely manufacturing of beverages. Manufacturing companies have been struggling for the optimization of supply chain and structuring it in the best suitable format to fit their demands of profitability and rationality. However, the current research findings have been continuously bringing about evidence of the fact that there is still much space for improvement and optimization, which can make the supply chain structure in the manufacturing sector more logical, optimal and will increase profit as well as upgrade the competitive advantage of the company, for which we may find an efficient literary basis serving as a proof of the problem existing in reality. For example, John Addison and Claus Schnabel (2003) emphasize the lack of benchmarking in the UK manufacturing sector in their study of the UK trade unions. During the comprehensive research on 600 UK manufacturing companies these scientists concluded there was no benchmarking in 1993 in the average case companies. Then comparing those workplaces to high performance work (HPW) plants the researchers found a substantial improvements in productivity results with total quality management and benchmarking (Addison and Schnabel, 2003). These research findings clearly supports the idea of authors indicating that the UK manufacturing industry is one of the most successful ones in the world, nevertheless being “much less familiar with measuring and benchmarking its own process manufacturing performance” (Ahmad and Benson, 1999, p. 1).

Benchmarking, despite its being an indisputably efficient tool of the company’s activities assessment also demands improvement. It is necessary that the existing benchmarking models being given priority nowadays be integrated with the purpose of creation of a more efficient, over-grasping and increasingly analytical tool to produce more effective benchmarking analysis of the manufacturing sector, as well as other sectors lying beyond the scope of the present study.

Research Questions

The present research is focused on the following range of questions to be answered and analyzed in the process of undertaking:

- How is the contemporary inter-organizational benchmarking process organized?

- What is the supply chain arrangement in a manufacturing company?

- What existing benchmarking techniques can be optimized and combined to produce a more efficient one?

- How can these techniques be applied for the specific categories of companies, namely the beverage producing company Diageo plc?

- What are the various aspects of analyzing benchmarking of a manufacturing company in different dimensions?

Objectives of the Study

The initial purpose of the present research is to investigate the key problems and issues associated with benchmarking in supply chain. The UK manufacturing sector will be benchmarked on the subject of reasonable arrangement of supply chain as a general focus of the given work. The objective underlying this research is the analysis of the whole supply chain process in a manufacturing company, with further observation on what pitfalls have been neglected and in which way the organization model fails to achieve higher productivity and profitability on the example of a separate company representing beverages manufacturing, i.e. Diageo plc.

Further intentions are producing a set of recommendations to use better tools for enhancing the existing benchmarking policy, to find a different perspective of benchmarking techniques investigation through conducting a deep and multifaceted study of existing benchmarking policies, recording their advantages and drawbacks, which will help to further create a more efficient integrated benchmarking technique and apply it to analyze the possible ways of the supply chain process optimization. The results of empirical research by implementing the integrated benchmarking model created in the present work to the analysis of Diageo plc will help make further inferences that might be successfully implemented by other manufacturing companies in the UK.

Scope of the Study

In the process of defining the scope of the study, a number of sources have been taken into consideration, including the specificity of research, the researcher’s personal interest and availability of sources of statistics on the national, local and international scale. As a result, the research was decided to be aimed at primary investigation of the supply chain arrangement in the UK manufacturing sector and existing benchmarking models that may be analyzed and integrated, with the further precise focus on Diageo plc. In the process of the research all significant elements of the study such as thorough consideration of BM techniques and supply chain management both on a broader, national scale, and on a precise, specified example of Diageo plc, were considered.

Literature Review

The literature review for the present work is focused on five areas of scientific interest in the sphere of benchmarking. The first area to be covered will be the concepts of logistics, supply chain and supply chain management as the key spheres for which benchmarking is relevant.

Then the focus will be made on benchmarking on the whole, with attention paid to the peculiarities of BM in the manufacturing sector of the UK, as it constitutes the prime interest of the present research. The next part of the literature review will be dedicated to five BM models the examples of which serve as a background for integration and creation of an advanced BM model for comparison with the Diageo Plc. Benchmarking policies.

The Concept of Logistics, Supply Chain and Supply Chain Management

Connections between Logistics and Supply Chain

At the beginning of the 21st century logistics became the focus of everyone’s attention since its growing importance in the process of arranging the production process and controlling the supply chain was recognized. This fact was understood from statistics: global logistics expenditures equaled $3.5 trillion and constituted about 20% of the global GDP (Frazelle, 2001). At that moment it became understandable that logistics needed to be paid closer attention to: “logistics is being recognized as perhaps the last frontier for major corporations to significantly increase shareholder and customer value” (Frazelle, 2001, p. 2).

In this context, Frazelle (2001) indicates close connection between logistics and supply chain management but admits that these concepts are often misunderstood, notes lack of professionally trained staff in the discussed sphere and explains failures to arrange logistics projects by these factors. He states that the most problematic outcomes are unmet promises and potential. These negative tendencies may be witnessed from the fact that an extremely small number of logistics projects are successfully accomplished, and the author believes that “the underlying cause of recent failures in logistics is that the tools, technology and training available to logistics professionals are not keeping pace with growing logistics complexities” (Frazelle, 2001, p. 3).

For this reason the work “Supply Chain Management” of this author is devoted to the whole multiplicity of aspects of the notion of logistics, being defined and thoroughly analyzed. First of all, it is clearly described by the author why it is hard to define logistics by explaining its core meaning as “the flow of material, information and money between consumers and suppliers” (Frazelle, 2001, p. 5). However, he shows logistics in its five contexts that complicate understanding of the concept enormously. These are workplace logistics, facility logistics, corporate logistics, supply chain logistics and global logistics.

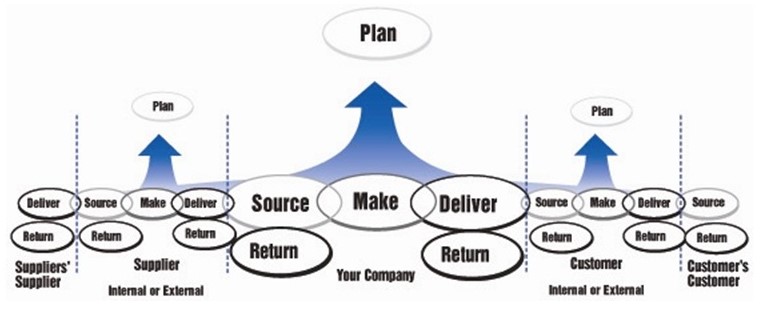

The focus of the present work is drawn at the supply chain, so it is more relevant to focus on the supply chain logistics. Figure.1 clearly shows the arrangement of logistics activities in the sphere of supply chain logistics:

Frazelle (2001) admits himself that it is hard to distinguish logistics and supply chain, thus defining the latter as “the network of facilities, vehicles and logistics information systems connected by an enterprise’s supplier’s suppliers and its customer’s customers” whereas the former is the range of activities taking place within the supply chain (Frazelle, 2001, p. 8). They include “customer response, inventory management, supply, transportation and warehousing” are serving as links and activators along the whole supply chain (Frazelle, 2001, p. 8).

Theoretical Research on Supply Chain Management

Handfield and Nichols (2002) also took an active interest in defining supply chain and supply chain management having an alternative, more complicated and structured approach to the discussed concepts. In their opinion, “the supply chain encompasses all organizations and activities associated with the flow and transformation of goods from the raw materials stage, through to the end user, as well as the associated information flows. Material and information flows both up and down the supply chain” (Handfield and Nichols, 2002, p. 8).

Paying separate attention to the issue of SCM, the authors define it as:

“the integration and management of supply chain organizations and activities through cooperative organizational relationships, effective business processes, and high levels of information sharing to create high-performing value systems that provide member organizations a sustainable competitive advantage” (Handfield and Nichols, 2002, p. 8).

Major Challenges in the Sphere

After considering various logistics activities comprising its essence, Frazelle proceeds to identifying problems that exist within the sphere. He states that “logistics problems tend to be complex and cross-functional” thus showing the need to establish a set of optimization techniques to develop better solutions (Frazelle, 2001, p. 15). However, in the process of optimization one should never forget about the contemporary problems and challenges logistics and SCM generally face in reality. As the research being conducted tends to be up-to-date, it is necessary to pay attention to the recent developments in global markets and technologies that introduce certain changes into the arrangement of the supply chain management process. According to Handfield and Nichols (2002), these are the growing consumer demands in all characteristics of the product (price, quality, delivery terms etc.); the evolution of higher-order mutual inter-organizational relationships; and evolution of informational technologies.

In the context of discussing the inter-organizational activities being developed one should pay closer attention to the fact that this tendency was already noticed in 1990 by an outstanding economist Bowersox in his article about strategic alliances formed by companies to share risks and benefits. He states that innovation in its essence comprises merging operations and obtaining mutual benefits, the growing value of production being the push towards the added logistics business and indicates a number of forces that contributed to the creation of favorable environment for such alliances including the political and legal relaxation, deregulation of transportation etc (Bowersox, 1990).

The Concept of Benchmarking

General Overview of BM

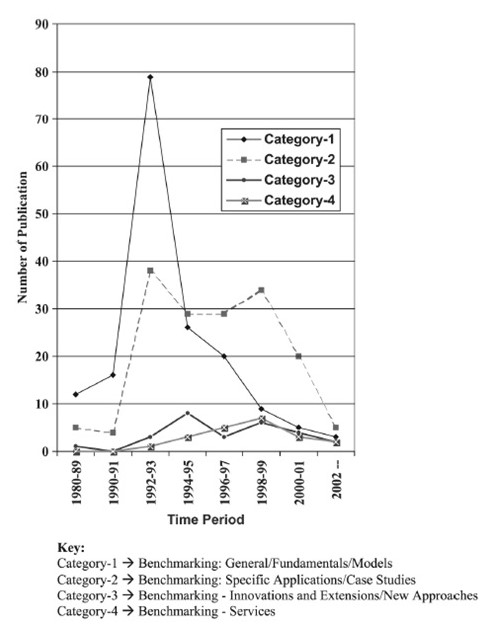

Benchmarking is not a new concept – it has been extensively used in a number of industries to introduce changes through monitoring the competitive industries’ success and finding out the possible strategies for change and innovation. It emerged in 1980s and since then took a significant place in the sphere of supply chain management, strategic planning and innovation, developing and evolving through time (Dattakumar and Jagadesh, 2003). The illustration from the following figure.2 indicates the categories involved in publication of benchmarking.

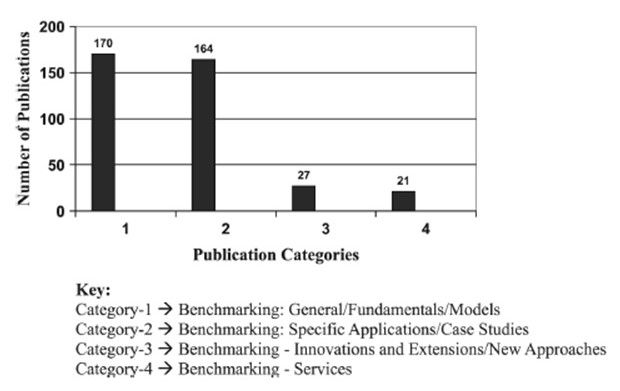

In general, theoretical research in the sphere of benchmarking has been conducted for more than three decades and yielded many constructive results, which again proves the point about the importance of the discussed concept in the framework of supply chain management and organization of the working process. Dattakumar and Jagadesh (2003) give a precise account of the number of publications dedicated to the issues connected with benchmarking, admitting that the share of research in different areas is different and the most popular fields of interest are case studies and general studies. The results of their investigation may be seen on Figure.3

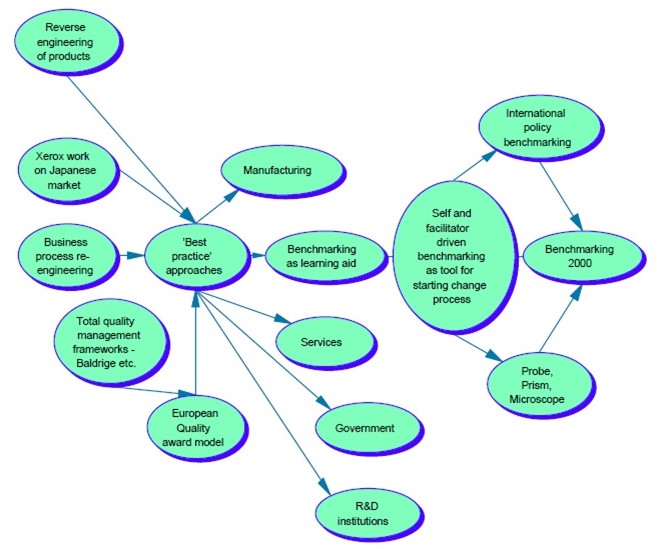

The researchers were also interested in the fields covered by the BM research, so the inferences they arrived at can be seen on Figure.4 that subdivides all available materials on BM according to their subject matters that have been shown on the Figure.3

The evolution of perception of BM and its role in the sphere of supply chain management may be traced not only by tendencies of focusing attention on subject matters to which the attention of Dattakumar and Jagadesh (2003) is turned. Such theorists on BM as Bessant and Rush (1998) also focus on the way approach to studying BM changed with the flow of time.

However, paying tribute to the adequate number of publications on the topic of BM that have become available recently and realizing the key importance of the concept in the field of management, one should still take a closer look at the essence of the concept. On referring the work of Andersen et al. (1998) dedicated to the issues of benchmarking it is first of all necessary to pay attention to the definition they give to it, referring to the opinion of APQC: it is the strength to admit the fact that some competitor may do something in the field better and to be prudent to seek experience from that company.

BM Activities and Process Peculiarities

The consideration of what precisely the BM activities should include and how the BM process should be conducted at the beginning have been acknowledged. The text presented below clearly insists the authors’ prominence towards his argument.

“the primary activities in benchmarking an MPC project are on the techniques, work practices, processes, changes required, information systems, and management of the overall project – all this with an eye to what can be learned and implemented in one’s firm” (Vollmann et al., 2005, p. 550).

However, the authors voice an unusual opinion about the true purpose of BM and the executives’ failure to achieve it. They indicate the bias that is inherent in every committed employee that nonetheless has to be overcome not to prevent the person conducting the BM study from thinking rationally and objectively. They stress the fact that even a successful and prosperous company always has what to learn and for this reason BM should be approached seriously “true benchmarking requires keeping an open mind as well as working hard to minimize defensive thinking. In far too many cases, supposed benchmarking trips result only in ‘feel good’ exercises where a team returns convinced of its own superiority. This is clearly faulty. One can always learn from almost any benchmarking visit” (Vollmann et al., 2005, p. 550).

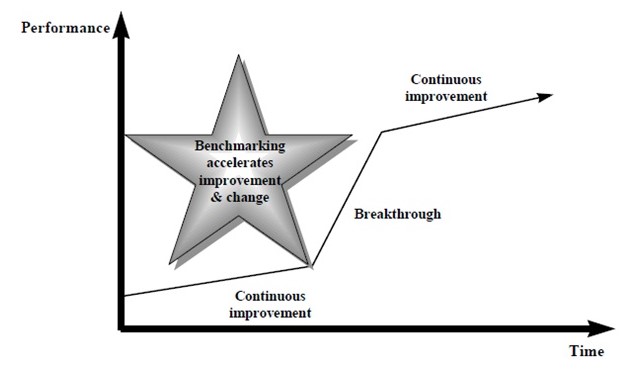

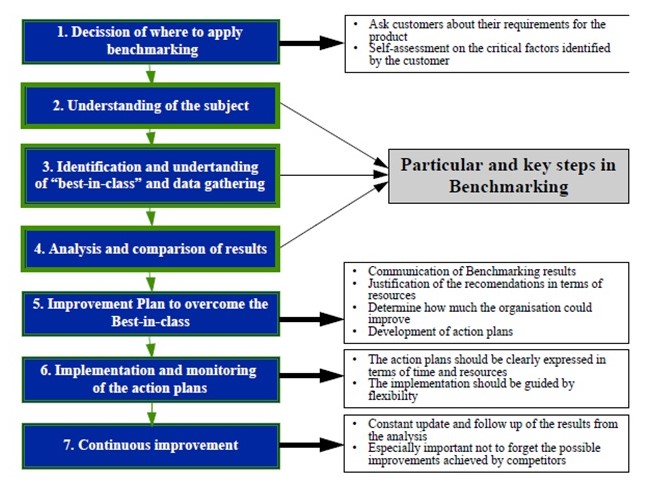

Andersen et al. (1998) go further in their analysis of BM and outline four key elements that constitute any BM process which includes measurement, comparison, learning and improvement as indispensible parts of BM that make it an efficient undertaking. The main aim of attaining continuous improvement through Benchmarking the processes involved is aimed at in every company as a final element, which can be seen from Figure.6

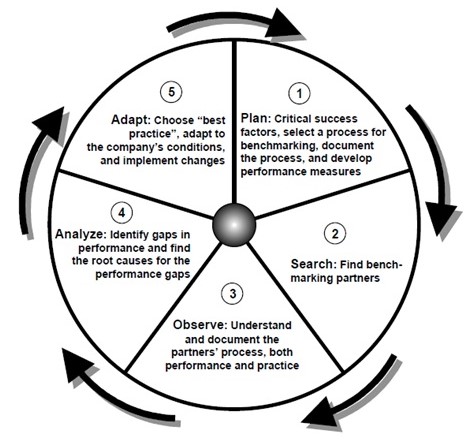

The authors deeply examine the procedure of conducting BM, steps that need to be taken to undertake research. This procedure includes a set of interconnected actions that in the end lead to success in case they are observed and correctly fulfilled. A more detailed description of the whole BM process as it is seen by Andersen et al. (1998) can be viewed on Figure.7 that represents a co-called BM wheel.

Positive and Negative Features of BM Research

Andersen et al. (1998) also paid much attention to all positive and negative consequences of the BM process: on the example of the empirical study they have conducted the authors have arrived at the following results:

- finding partners suiting in size, specialization etc. and willing to assist and share their best practices is hard;

- lack of access to financial information that is unwillingly disclosed by potential competitors is also a challenge for conducting BM;

- lack of business process understanding is a problem that is rarely taken into consideration seriously;

- low comparability of companies is a common situation that is likely to hinder the BM process (Andersen et al., 1998).

Analyzing their research further, the authors assess positive characteristics of the process. First of all, they state that assessment of the current status of the partnering company should be done long before the direct BM process because it constitutes a huge part of the BM workload and may affect the results if not conducted in a timely manner. They also emphasize the role of questionnaires in the BM process and advice composing them beforehand to make sure all relevant information is properly recorded. The last issue they turn the reader’s attention to is the fact the efficient BM process may be conducted only under the condition of being knowledgeable about one’s own business process and its peculiarities. Only under this condition the company will be able to adequately assess the differences with another one (Andersen et al., 1998).

Vollmann et al. (2005) also support the opinion of Andersen et al. (1998) about the process of BM – coming and accessing freely available information, asking employees to fill in the questionnaires and conducting interviews is very important and should be done on a preliminary basis, as they state. Nevertheless, they also state that a company may benefit from being benchmarked. The author determines “any visitors to your operations are potential sources of new ideas… any learned person visiting an operation will have some thoughts as to improvements that can be easily gathered by the representatives of the firm visited” (Vollmann et al., 2005, p. 550).

Proceeding to the theoretical background about benchmarking in process industries, one should note that the authors’ emphasize BM being focused on business processes, which may be hard to assess because of “one business process may affect more than business measure” (Ahmad and Benson, 1999, p. 88). For this reason, in order to facilitate the BM interpretation, Ahmad and Benson (1999) offer a set of tools for data representation, e.g. a spider diagram, a box and whiskers diagram etc.

Benchmarking in the UK Manufacturing Sector

Benchmarking in the manufacturing sector is usually done according to performance measurement systems. These tools for assessing the production process have become strategically important with the coming change in the industrial field as well as the emergence of necessity of continuous quality management and re-engineering procedures “Manufacturers have used performance measurement in two important ways, either before the adoption of new philosophies such as total quality management (TQM) and lean production, to help to identify weaknesses and to define current levels of performance, or following the adoption of these philosophies, to monitor the outcomes and effectiveness of various implementation strategies. Often it is used for both” (Best and De Valence, 2002, p. 277).

Changes in UK Manufacturing Sector BM

It is evident that nowadays approach to managing the manufacturing sector is undergoing a consistent change. The matter is that substantially different process indicators acquire importance and become the focus of management process, shaping BM activities in a completely different way:

“The key to the successful use of performance measurement by the manufacturing sector has been the fundamental shift from traditional management accounting-based measurement systems to new, operation-based financial and non-financial performance indicators” (Best and De Valence, 2002, p. 277).

The growing importance of BM in the manufacturing sector does not cause any doubts any longer. In the sphere of manufacturing it is clearly admitted the impact of low level of BM on the overall productivity indicators. Their work was dedicated to the analysis of trade unions and organization of their activities in the manufacturing sector of the UK economy. In the section of analysis of this sector the authors admit that absence of BM and poor production indicators as well as human resources management characteristics are interrelated. While studying companies with a higher level of employee engagement and higher BM indicators the researchers indicate the positive effect on productivity (Addison and Schnabel, 2003).

In general, the positive influence of BM on different aspects of manufacturing sector’s activities have been recognized a couple of decades ago, thus initiating intensive work in the UK to build a sound basis for further BM analysis. In the context of discussing the present issue the work of Griffiths and Wall (2007) is also highly relevant. They indicate the increase in understanding of competitive advantages and weak sides in the majority of industries in Europe due to the growth of BM analysis activities in the UK. They state that “benchmarking occurs when companies set out to compare themselves systematically with the best in their industry, thus helping them to establish targets for improvement” (Griffiths and Wall, 2007, p. 561).

The UK initiated intensive action in the sphere of BM: the main evidence of this is the joint effort taken by the DTI, British Quality Foundation, the CBI PROBE initiative and Cranfield University to establish the National Benchmarking Network in 1996 (Griffiths and Wall, 2007). UKBI (The United Kingdom Benchmarking Index) is another achievement of the UK BM providers – for 4 years of existence there have been generated 60 measures according to which BM is presently undertaken in the UK:

“These included profitability, return on net assets (RONA) growth, innovation, investment, cash management, customer satisfaction and operations and people management. It is through such networks that the increased quality and productivity necessary for competitive experts might be secured” (Griffiths and Wall, 2007, p. 561).

BM is continuously done in the UK manufacturing sector and yields efficient results enabling any researcher to produce objective judgment on the issue. According to the results of the Benchmarking Index Survey, the top quarter of manufacturing companies shows a dramatic gap in productivity and profit, thus making it much complex for other companies to rise on the scale. The reports on BM also indicate a set of problems that seek immediate practical action, hence proving their efficiency and relevance to the present-day situation in the manufacturing sector. BM reports of the UK gives an indication of the poor quality in process industry “a benchmarking report on the UK’s processing industries (chemicals, pharmaceuticals, plastics, rubber) in 2001 suggested quality problems for the UK processing industry in that its defect rate of 6.5 per 100 compared unfavorably with the world-class level in this sector of 1 per 100” (Griffiths and Wall, 2007, p. 561).

Sources and Types of BM

Following the established scheme of BM analysis, it is relevant to turn to the opinion of Ahmad and Benson (1999) enumerating the following sources of benchmarks: performance outputs, customer performance, customer complaints, delivery due data, adherence to production plan and stock return. Types of benchmarking are also important to be considered in the course of discussing BM in the manufacturing sector: Hinton et al. (2000) outline such popular types of BM as internal (BM of one’s own organization), competitive (comparison of indicators with competitors), functional (comparison of similarly functioning companies in the same sphere) and generic process (comparison with companies using not typical, innovative working processes) benchmarking. The proportion of each type of benchmarking in the UK may be seen in Figure.8

One can see practical applications of the facts laid out in the present chapter on the example of BM report prepared by the Cranfield University on the performance of the UK manufacturing sector. The report of Cranfield School of Management is a wonderful example of BM of the manufacturing sector. At the very beginning its creators enumerate goals and objectives it covers:

“The report is structured to address, firstly, the relationship issues that a company has with each of its key stakeholders – its investors, customers, employees and suppliers. It then goes on to dissect essential performance measurement issues that pertain to implementing strategies and then, importantly, the business processes and capabilities that must be put in place in order to deliver the strategy” (Neely and Adams, n.d., p. 2).

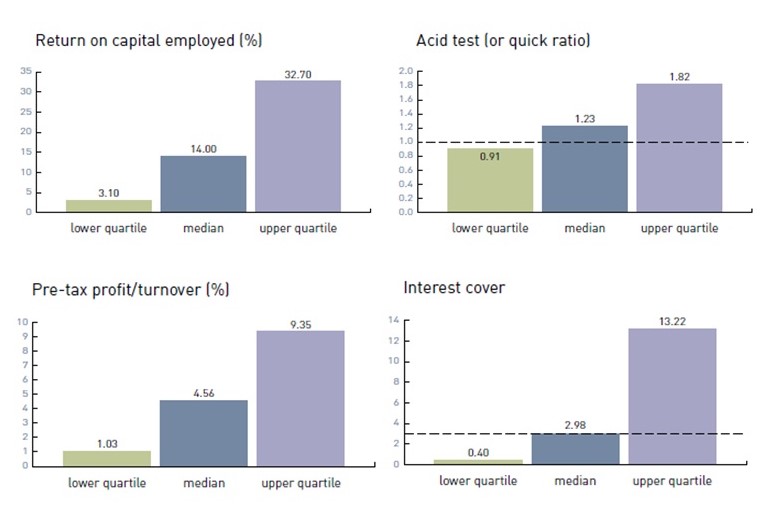

The report is designed to assess main characteristics of the sector – rather than focusing on separate companies, the researchers defined by classifying it by upper segment, the lower segment and the median part of the enterprises according to their economic indicators. The first measure to be assessed is the companies’ being subject to risk and reward. The main variables are pre-tax profit/turnover, return on capital employed, acid test and interest cover. The BM results may be seen on Figure.9

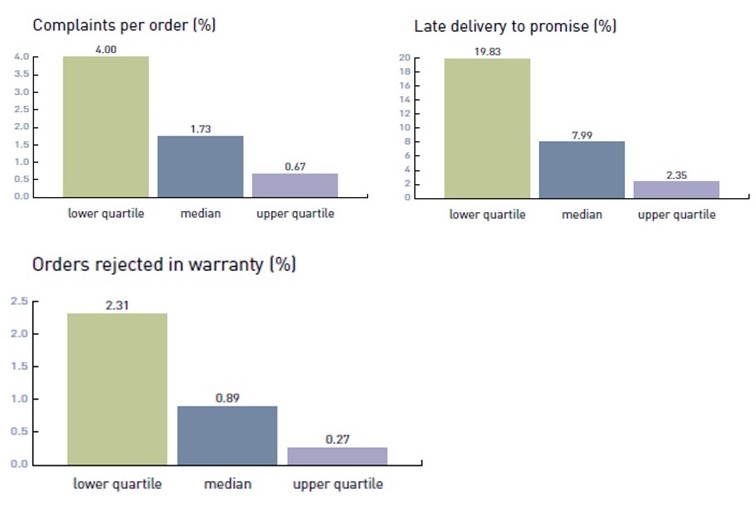

Accepting the fact that performance depends much on customer satisfaction, the researchers measure several variables that indicates its level. The results are based on their judgment of these variables: complaints per order, late delivery to promise, orders rejected in warranty (Neely and Adams, n.d.). The results of BM analysis in this aspect may be seen on Figure.10

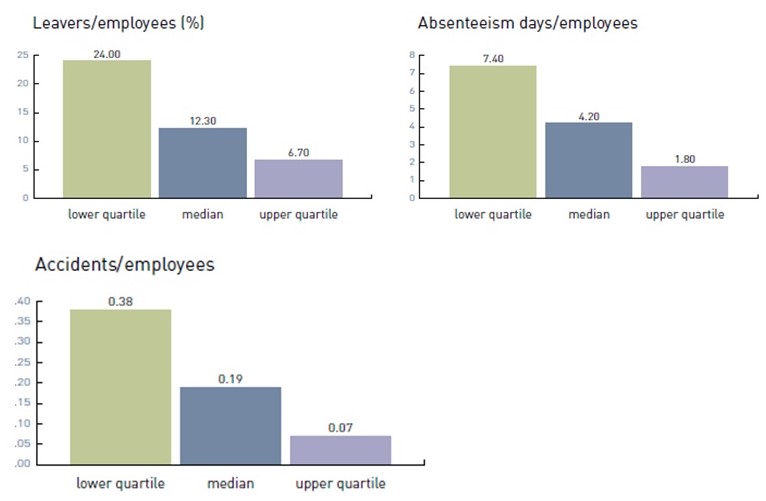

Employees are also a key factor throwing light on the level of the company’s performance. Figure.11 clearly shows the main variables used in the BM Index to judge the level of employee satisfaction:

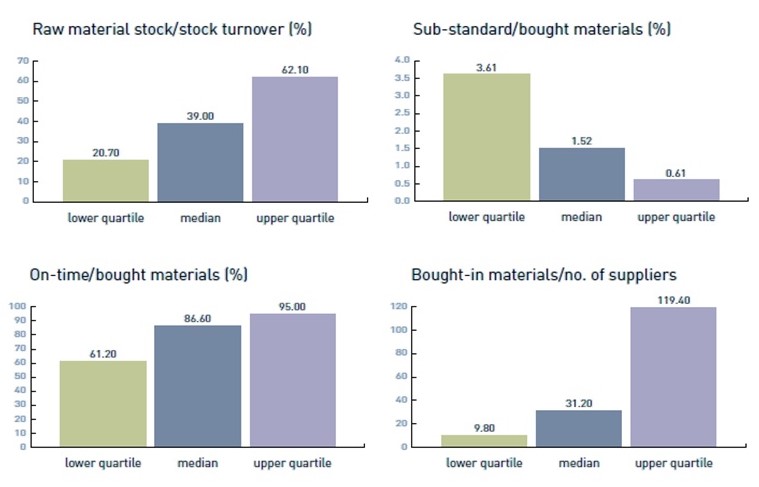

The next strategically important element of forming a comprehensive BM picture of a company working in the sphere of manufacturing is the suppliers’ viewpoint about the company. The main variables for assessment are sub-standard/bought materials, on-time/bought materials, raw material stock/stock turnover, bought-in materials/no. of suppliers (Neely and Adams, n.d.). Figure.12 illustrates the results of analysis according to the mentioned indicators:

Among other issues that are closely considered in the context of BM the manufacturing sector one should pay attention to the issue of strategies for growth and development (new product development: R&D, new products percentage, new products sales turnover, product to market time; and people, technology and infrastructure: capital expenditure/turnover, capital expenditure/depreciation, training costs/employees) (Neely and Adams, n.d.). Business processes, operating cash flow and organizational capabilities are among other relevant variables that shape the overall BM image of the manufacturing sector in the UK (Neely and Adams, n.d.).

Aims and Awaited Results of BM in the UK Manufacturing Sector

Summarizing all information received in the course of analyzing theoretical foundations of BM concepts pertaining to the analysis of the UK manufacturing sector one has to keep in mind the inferences made by Campbell et al. (2002) as to the prime aim and the awaited result of any BM process. The researchers make the major emphasis on the importance of the final stage of BM that is actually the sole aim thereof: improvement. They note that comparison should yield results that may become instigators of innovation, which will actually become the success of BM:

“Successful benchmarking usually rests upon the premise that competitors in an industry are willing, to some extent, to share, collaborate or make information available upon their performance and processes. The happy result of successful BM is that all participants in an industry have improved quality performance, so improving customer satisfaction with the industry’s products” (Campbell et al., 2002, p. 249).

These are the main theoretical considerations that have to be seriously taken into account when analyzing BM as a concept and its peculiarities in the UK. Process industries are substantially different from, for instance, service industries, which seriously affects the variables chosen for conducting the BM analysis in any manufacturing company and the whole process of BM. The researchers should easily distinguish these peculiarities and design their BM framework accordingly.

Analysis of Five Benchmarking Models

SCOR and BPR Models

One of the most widely used models is the Supply Chain Operations Reference Model (SCOR) that is fairly considered as an ideal model because of its comprehensive approach to SC analysis. It is applied in the evaluation and comparison of SC’s performance potential, analysis and optimization of integrated SCs “throughout partners within the logistic chain”; and proper arrangement of software within the SC (Poluha, 2007, p. 50).

According to Demirag (2006) description of the SCOR model, it is based on five management processes that can be seen on Figure.13

Another popular model is Business Process Re-engineering (BPR). It includes analysis and change of existing BPs both inside a certain organization and between organizations. The prime aim of BPR implementation is improvement in performance (Radhakrishnan, n.d.). The BPR usually means remarkable change in all aspects of the company’s functioning including its “organizational structure, management systems, employee responsibilities and performance measurements, incentive systems, skill development and the use of information technology” (Radhakrishnan, n.d., p. 9). The key difference of BPR from other approaches to introduce improvement is, according to the opinion of Kulpa and Johnson (2008), the selection of BPR for high-level BPs, e.g. corporate governance.

The EFQM Model

The next BM model investigated in the course of the present research is the European Foundation of Quality Model (EFQM). The author applied the EFQM in the evaluation of external quality mechanisms for health care. It is an assessment model widely accepted in the EU countries and developed by the Baldrige Awards in the USA “for improvement of quality in production industries” (Shaw, 2000, p. 171). The model is “characterized by a graphic conceptual framework” – it focuses on management systems (Shaw, 2000, p. 171). In the assessment process according to the EFQM such activities as site visits (external visits, surveys, assessment), checking validity of standards etc. are involved. In general, the model is described as an “explicit, tested and consistent framework to describe the scope and relative weighting of assessment domains” (Shaw, 2000, p. 173).

Six-Sigma Lean Management

Six-Sigma as a management program (and a BM model, as in our case) is one of the most popular programs in the USA that was worked out by the Motorola Corporation (Arnheiter and Maleyeff, 2005). Despite the common opinion that six-sigma and lean management are similar concepts, they are basically different, which requires separate attention in the context of the present section.

According to the opinion of Arnheiter and Maleyeff (2005), six-sigma has emerged as a response necessity to ensure high quality of final products at the manufacturing companies where the production process involved composition of the product of a large number of components. A certain step manufacturing process is likely to yield many defective products: to eliminate this undesirable drawback the six sigma approach was adapted. Lean management emerged as a natural response striving to produce as few undesirable by-products as possible and to make the production process more ecologically safe and economically profitable (Arnheiter and Maleyeff, 2005).

Though the reason for their emergence is deferred, the result achieved was highly similar, which actually caused misinterpretation:

“Both Six Sigma and lean management have evolved into comprehensive management systems. In each case, their effective implementation involves cultural changes in organizations, new approaches to production and to servicing customers, and a high degree of training and education of employees, from upper management to the shop floor” (Arnheiter and Maleyeff, 2005, pp. 5-6).

However, it is important to understand the secret of success of the six sigma model. According to the opinion voiced by Pfeifer, et al. (2004), it is the six-sigma level that distinguishes six-sigma and provides for its benefits: “The sigma level is a benchmark for the ability of a process to accomplish the demanded requirements” (Pfeifer et al., 2004, p. 242). Organizational structure is the key focus of six-sigma – both on management and operational level. Customer satisfaction is also one of the chief objectives of six-sigma.

There is a set of success factors of six-sigma and competitive advantages distinguishing the discussed model from others. They include the prioritization of customer agreement on project objectives and continuous control of results; focus on essential BP; usage of approved, efficient tools, continuous work on employee satisfaction and resources allocation (Pfeifer et al., 2004).

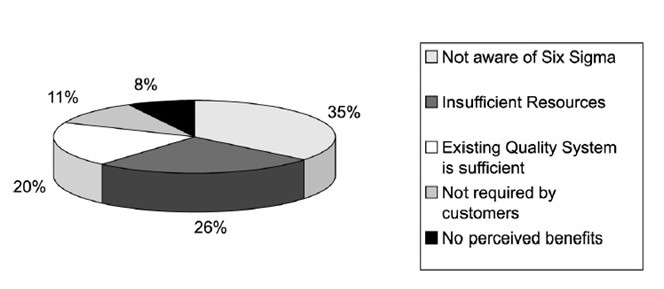

The reason why the Six-sigma has chosen as a model for analysis in the present work because it proved highly efficient and rewarding for many UK manufacturing companies due to its four advantages outlined by Antony, et al. (2005):

- it is heavily focused on the savings that may be generated from the project, thus ensuring its profitability;

- continuous improvement is approached from both the angle of human resources and BP;

- the six sigma methodology unites tools and techniques in a natural and cohesive way;

- it creates a powerful infrastructure for training.

Despite these indisputable benefits there is still a set of reasons enumerated by manufacturing companies given for not implementing the six-sigma approach. They require consideration in the context of the present research and can be seen on Figure.14

DMAIC and PDCA

Continuing the discussion of six-sigma, it is necessary to note that one of the ways of its implementation is through the DMAIC methodology. Its abbreviation is “Define Measure Analyze Improve Control” – it is used when a BP does not correspond to required reality and seeks change (Haouzi et al., 2009). The stages of this model may be described as follows:

- Define: the stage involves stipulation of goals, the ultimate objectives, elements of the company’s functioning involved etc. (Haouzi et al., 2009);

- Measure: the stage requires transforming customers’ responses into metrics that can be measured with further generation of ideas on possible ways of improvement (Haouzi et al., 2009);

- Analyze: this stage may be conducted through application of Pugh matrix – the tool of evaluating multiple options against a particular chosen baseline option (BM). It functions as a link between the customers’ desires and engineers’ capabilities (Haouzi, et al., 2009);

- Improve: this stage involves practical implementation of theoretical considerations of the previous stages (Haouzi, et al., 2009);

- Control: the final stage involves continuous control over the process of the improved BP’s functioning and its effect on the customer satisfaction (Haouzi, et al., 2009).

The last model to be considered is called the PDCA cycle, or Deming cycle, or Shewhart cycle, the process of implementing which can be seen on Figure.15 (Tague, 2005).

The main objective of the Deming cycle is continuous improvement that is undertaken in cases where improvement is needed by the company seeking change or wants to identify the problem and its root causes (Tague, 2005). The procedure of the cycle looks the following way:

- plan (establish the necessity for the change and plan it);

- do (through a study check the possibility of change);

- study (analyze the results of the test and identify the acquired experience);

- act (take appropriate actions on the implementation of the change based on the results of the testing analysis) (Tague, 2005).

Conceptual Framework and Methodology

Conceptual Framework

The conceptual framework of the present research is focused on a number of items constituting the major interest in the discussed scientific area. Consequently, it is necessary to build up a cohesive structure in order to link these concepts into one integral unity and operate them more freely in the course of conducting the research.

The broadest concepts being considered in the present work are supply chain (SC) and supply chain management (SCM). They occupy the central place in our framework because BM is the tool for arrangement of successful SCM and the SC is the central issue of concern in the whole production process of any company. Only under the condition of wise and reasonable arrangement of SC and strategically designed SCM the company may succeed in its business activity.

Thus, for the purpose of detailed and explicit introduction of these two concepts I rely heavily on works of Frazelle (2001) introducing the concept of logistics and concentrating on the importance of logistics in an organization; Handfield and Nichols (2002) taking their active interest in the anatomy of SC and the way SC as well as SCM evolved; and Bowersox (1990) who nearly 20 years ago already understood the coming tendency of building up strategically profitable logistics alliances and examined reasons and motivation for their creation. Bowersox also attributes attention to the forces dominating the creation of favorable environment for alliances and enumerates benefits they may bring as well as possible reasons for their failure.

The following concept building up our framework is BM as a tool of assessing the current situation in an organization on the basis of comparative analysis on a set of key indicators important for the company’s functioning. BM is the central issue of the present research as it is the prime tool of analysis, evaluation and processing. In the context of discussing BM I was guided by material Andersen, et al. (1998) who provide a detailed description of BM, define it and enumerate its elements, also dealing with challenges and successes of BM, including the most common pitfalls a company should take into consideration and not repeat; Vollmann et al. (2005) who focus on the role of BM in the process of the company’s functioning; and Ahmad and Benson (1999) who together with the Institution of Chemical Engineers (GB) produced an informative summary of BM in the process industries – its origin, role, implications, types, sources etc. This book offers a huge amount of useful information necessary to facilitate the reader’s understanding of the BM concept, since it constitutes central importance in the present work.

Further on the research will be concentrated on the concept of BM in the manufacturing sector of the UK economy. It is necessary as every segment has its own peculiarities of SC, different BM principles and metrics that bring about varied managerial implications. In this respect first of all the work of Addison and Schnabel (2003) represents particular interest: the authors conduct analysis of manufacturing sector in their study of trade unions indicating lack of BM. Best and De Valence (2002) devote much attention to the history and overview of BM in the manufacturing sector, giving much material worth close consideration in the course of the present research. Griffiths and Wall (2007) describe growth of popularity of BM in the UK and results of the BM studies, especially in the sphere of the manufacturing sector. Campbell et al. (2002) pay their close attention to metrics used to benchmark the manufacturing sector. Scholes and Johnson (2001) explore BM as a strategy implemented by XEROX in part of their photocopy manufacturing. Finally, the case study conducted by Cranfield University specialists gives statistical BM results in the manufacturing sector in the UK for the recent years. All this information will be helpful in constructing a strong theoretical basis for further design of a new BM model for manufacturing industries.

The final part of the literature review will be dedicated to the analysis of five BM models chosen for integration and consideration – they are SCOR, BPR, Six-sigma, DMAIC and PDCA. The characteristics of these models will be outlined with the purpose of defining the strong and weak sides of the chosen approaches with the further integration thereof.

Research Design/Methodology

While choosing the methodology tools such issues as efficiency in processing information and obtaining relevant knowledge have been considered. The present research will be qualitative – inductive methods will be used to generate general understanding of the benchmarking models and practices within a specific sector of the UK economy that proved to be successful in the field. Afterwards, the data about various benchmarking models applied in the manufacturing sector that is the subject of the research will be synthesized and analyzed to determine the peculiarities and common strategies of establishment of a successful benchmarking model, to find an innovative approach that would enhance the companies’ success and productivity.

Methodology of the present work involves undertaking several steps: the initial stage is conducting a literary review to collect the materials and gather the theoretical basis for the continuation of analysis. The existing benchmarking techniques will be theoretically investigated to define their basic concepts and generate an innovative, integrated benchmarking model that would combine the strong sides of all discussed models and would eliminate their drawbacks. The second stage will be practical analysis of the created model by applying it for comparison with the benchmarking model of Diageo plc with the purpose of producing a set of suggestions on how this company would be able to optimize its activities with the application of the newly created benchmarking model.

Data Collection Methods

There were two sources of data chosen for the present research: primary sources included interviews, questionnaires, analysis of the chosen company and its benchmarking reports; secondary sources included theoretical data collection from relevant research projects, books, periodicals, websites and statistical benchmarking data sources. However, the Diageo plc administration were unwilling to reveal the results of recent BM studies, this is why it was necessary to eradicate the practical part of live communication. Consequently, the main information empirical analysis will be based on is the 2003 BM information broadly available on Diageo plc as well as the latest financial reports revealing the aspects mentioned to be benchmarked in the latest BM research.

In the process of conducting my secondary research I searched for theoretical information concerning supply chain and supply chain management, their evolution and peculiarities of these concepts directly pertaining to the issues of benchmarking. Besides, I needed information on the concept of benchmarking in general, its descent, the range of applications and specificity thereof when applied to the manufacturing sector supply chain. In this respect books on economics, logistics, benchmarking and supply chain management were very helpful and enabled me to collect the necessary amount of data. Periodicals and websites were also of much assistance as they offered updated, recent information on the mentioned topics, thus making my research more specifically focused to my objectives. In addition, statistical information from governmental sources as well as case studies on recent benchmarking research facilitated my understanding and analysis of the current situation in the context of benchmarking studies. Implementation of findings from secondary research sources helped me create a multi-faceted, comprehensive benchmarking model and conduct efficient comparison with the benchmarking technique of the chosen company.

Primary data collection method was specially designed to collect credible, full and updated information on the researched company from direct interaction with its representatives. The focus group chosen was a set of manufacturing sector companies in the UK, so direct communication was impossible to organize as it required actions and effort on a too wide scale; however, on accomplishing theoretical research and creating the integrated model of benchmarking I needed additional information from Diageo plc to conduct the advanced benchmarking research on it and indicate pitfalls of the presently used benchmarking technique thus proving my hypothesis about the possible range of improvements possible to be introduced in the present benchmarking process. For this reason I included the elements of an observational survey into my method of data collection – it was hard to reach the employees of Diageo plc and receive the necessary information, However, judging from the point that all relevant commercial information may be widely available in the literature issued by the company, its commercials, financial reports and internet press releases.

Methods of Data Analysis

Methods of data analysis chosen for the present work are specified according to the peculiarities of the work itself. Since it includes both numeric and textual data as chief sources of information relevant for the discussion, it is necessary to keep in mind that two ways of analysis will be implemented.

Numerical data will be represented and analyzed in the form of tables, charts and diagrams to ensure accuracy of analysis. Comments on the visuals will be inserted in the text with proper explanations to facilitate the reader’s understanding of main purposes of this data usage and to make sure of patterns in it.

The textual part analysis, namely the BM integration process based on numerous theoretical assumptions and inferences will be based on the content analysis with the proper understanding of the fact that the true meaning of concepts I am looking for lies within the text but not in my personal interpretation.

Thus, on the basis of such combined methods of data analysis I plan to arrive at the logical, practically and theoretically grounded conclusion about the innovative BM technique that may be successfully introduced in the BM research process. The results will contain both numeric and textual data as well, thus assisting the comprehensive understanding of the research results.

Limitations of Research Methodology

The present methodology has a certain set of limitations that should be thoroughly considered when assessing the results of the study. First of all, the benchmarking techniques viewed in the present dissertation from which an integrated model is constructed are not the ultimate number of BM models existing in economics at the present moment of time, so the model created in the process of the present research may undergo further changes, alterations and improvement. Besides, the process of assessing strong and weak sides of BM models chosen for the present dissertation, though being strongly supported by preliminary literature review and relying heavily on the opinions of outstanding specialists in the sphere of economics, logistics and supply chain management, still partly represents the subjective opinion of the researcher and should not be taken as ultimate objective decision on the possible integration of BM models’ characteristics.

In addition, information received from Diageo plc pertained only to the specific areas of BM research I was interested in according to the newly created benchmarking model; this is what may impose certain limitations on the assessment of the company’s characteristics. A part of characteristics have been omitted in the process of constructing a new BM model, thus facilitating the enlightenment of particular spheres of the company’s activities and throwing shadow on others. Thus, the results of BM of Diageo plc according to the newly taken model should be accepted in the whole scope of characteristics chosen.

Diageo Case Study Application

Integration of BM Models

The present chapter will deal with the correlation of the five BM models discussed in the section of literature review and outlined as the most popular approaches to BM and innovation. Here we have decided to work out the main principles of integration of basic BM concepts that would best fit the BM process and improve it to the extent the research requires.

The first stage necessary to go through in the process of integrating the BM models is to understand the generic BM process underlying the formation of any BM model in SCM. Bessant and Rush (1998) outline the main objectives that a BM model should satisfy in order to become sufficient and effective in the course of completion of its goals. First of all, the objectives of the BM process should be clearly formulated (it can be competitive, process, functional or generic BM) and BM activities should be carefully planned (the aspects to be considered are the activity level, intra-firm processes, inter-firm processes, out-of-industry BM) (Bessant and Rush, 1998). In general, the researchers illustrate the process of a BM model formation the following way:

According to Fawcett et al. (2008), authors have voiced an idea that the main barriers for SC collaboration and multifaceted cooperation of different BM models in a company may be found both in the field of the inter-firm collaboration and in corporate cultures. Thus, the change should first of all bear the cultural character – without the cultural change elements no change will be sufficient enough to be effective in the long run.

Some other considerations outlined by the author that guide the choice of BM models for manufacturing companies in the modern conditions – they state that the companies have to make sure they have “quality beyond the competition; technology before the competition; and costs below the competition” (Anand and Kodali, 2008, p. 258). Thus, it is evident that the choice of BM metrics and characteristics should also fit these demands and create the comprehensive image of the industry as well as the particular company.

Making inferences from the problems outlined by prominent researchers in the sphere of SCM and BM, we can draw a conclusion that the application of the BPR approach to BM may positively affect the problem of inadequate information sharing and turf conflicts because of the specific BPR features:

“BPR is a process approach that concerns internal modifications of the company organization in order to attain better internal collaboration within an organization” (Crestan, Neubert and Bouras, 2006, p. 1).

The issue of inconsistent metrics may be solved with the help of application of typical features of the EFQM because of its heavy emphasis on standardization and compatibility with the stipulated standards. Going further in the analysis of the most common problems for building up a successful BM framework, one should mark the issues of quality, technology and costs. These considerations are successfully covered with the discussed models: as it has already been said, the six sigma approach and its methodology DMAIC are mostly concerned with costs reduction and financial security of projects, the SCOR model covers all issues including the product quality and, consequently, customer satisfaction, and the PDCA approach keeps track of the continuous improvement that may be successfully applied to technological improvement on an uninterrupted basis.

Drawing a conclusion from everything that have been laid out in the present section it is important to note that the creation of an integrated BM model is possible only with consideration of all issues the five discussed models cover. Only under these conditions the researcher will be able to investigate all spheres of the company’s functioning and enumerate the aspects seeking change as well as the most efficient and constructive ways to implement this change and ensure its success on a long-term basis.

Justification of Company Choice

The present work, as it has been stipulated at the very beginning, is aimed at the creation of an integrated BM model for company analysis with the purpose of its further application to analyzing a company producing beverages and whisky, namely Diageo plc. As a result of our theoretical research on existing BM models it has been found out how BM analysis can be improved and made more comprehensive.

The choice of Diageo plc at the subject of our analysis can be justified in a number of ways. Its activities surely go beyond the measures of the UK, so it may be justly referred to as an international corporation. Also, the main reason constitutes for short listing Diageo plc is data availability. However, it possesses a large share of sales in the UK beverage market and has a “leading position in the spirits industry”, a “strong portfolio of brands, size and scale, and superior capabilities in distribution, marketing and pricing” (Diageo plc, 2006).

These characteristics together with well-diversified, annual turnover make it a reliable company for obtaining and considering multi-aspect, diverse marketing, production and resources data that will help us generate comprehensive, intelligible conclusions further applicable for broader BM research.

Judging from the information derived from 2006 reports it is necessary to mention that Diageo plc has a completely positive economic growth and development profile – their activities have been marked with healthy growth rates in the US market and multiple developing markets (Diageo plc, 2004). This growth was mostly explained by the ever-increasing growth of beverage consumption and demand for beverages of premium quality (Diageo plc, 2004). In fact, it is possible to suppose that it is due to the extensive activities of the company management in the range of spheres that ensured the company’s maintenance of ‘stable profit levels’ and strong and stable cash flow (Diageo plc, 2004).

The BM study conducted in 2003 showed an extremely high position of Diageo plc in the UK manufacturing market, so the choice of this company does not cause any doubts. Besides such positive economic indicators one should take into consideration the active, intense attention of Diageo senior management paid to the provision of BM research and investigations that find further practical application in the company’s daily operations. A vibrant example of implementation of Diageo BM findings in the empirical side of their research and functioning can be seen in their adoption of an innovative Manufacturing Intelligence Solution which will be described further on.

Diageo BM Discussion

Diageo plc is one of the progressive companies of the 21st century that realizes the critical need of continuous improvement and conducts frequent, large-scale BM studies in its segment of the international market. Its management has adopted a constructive approach to BM and has managed to avoid the commonly faced challenge of accepting and detecting pitfalls as well as mistakes in the operation process. They consider gaps revealed in the BM research process not as a negative notion but as a “substantial difference that might merit further attention or signal a firm’s relative strength or weakness for the coming fiscal year” (Diageo plc, 2004).

Diageo plc Previous BM Activities

Since there was no ability to obtain current BM results from the Diageo representatives, it appears appropriate to first examine the broadly available 2003 Diageo BM data to proceed with further considerations of the company’s activity. We have managed to obtain the BM scheme adopted by Diageo in 2009, so comparison of 2003 data, 2009 BM indicators and current BM trends implemented by Diageo is likely to yield awaited results – the diachronic picture of evolution of the BM techniques preferred by Diageo plc up to the present moment.

The first measure achieved by Diageo in 2003 was the Environment Index that appeared to be substantially high for Diageo. The first indicator that won the company the second position out of four was the overall management and performance benchmark. The results of research may be seen on Figure.16

The first subdivision of the present indicator is environmental management. This aspect of managerial activities in Diageo implies to what extent understanding of core environmental implications is developed within the managerial staff of the company and how well it is integrated in the company’s business strategy. The BM results obtained during Diageo investigation can be seen on Figure.17

The core areas of environmental performance are defined by global warming (GW), energy (E), transport (T) and solid waste (SW) issues. The rate of Diageo’s compliance with the generally adopted environmental standards is shown on Figure.18

One more BM indicator included in the 2003 BM report on environmental safety of Diageo’s production activity was the selected impact areas rating that can be seen on Figure.19

The Business in the Community Organization has also conducted BM studies in Diageo concerning the Corporate Responsibility Index. The overall company results again putting it on the second place in the rating can be seen on Figure.20

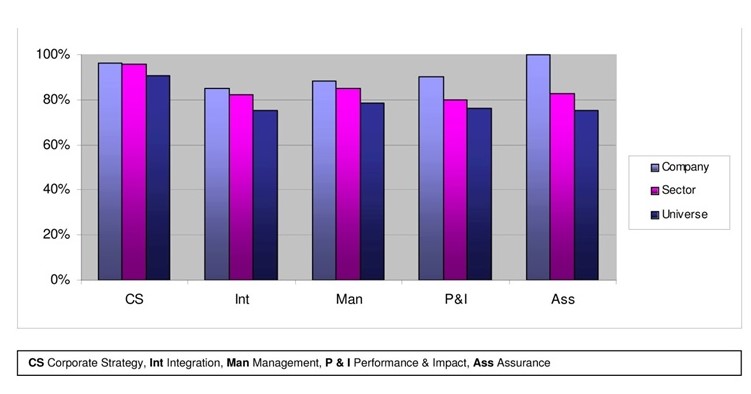

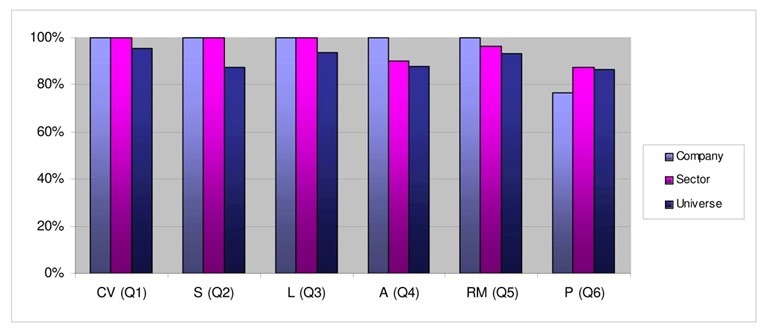

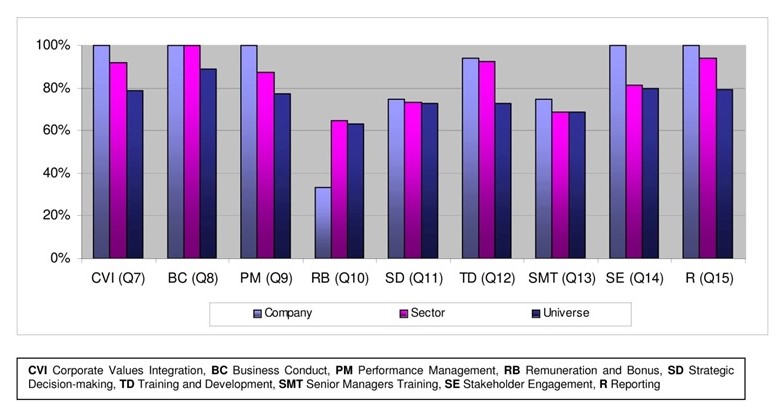

The overall performance data has been derived from considerations and analysis of separate aspects’ analysis. Particular Diageo results on every sector may be seen on Figure.21

These aspects appear to represent the core importance in the process of considering corporate responsibility. Their further analysis is certain to give a distinct idea of performance measures of Diageo. Thus, they have undergone detailed investigation on a set of characteristics, the result of which may be seen on Figures 22-25.

The BM research in Diageo was not limited only to the mentioned issues in 2003: to acquire the full understanding of the scope of BM research conducted then one should mention such areas of research as ‘Dow Jones Sustainability Index’, ‘FTSE good index series’, ‘gradient index on the management of supply chain labor issues’, ‘corporate community involvement index’, ‘carbon disclosure project on climate change and tomorrow’s people trust evaluation executive summary’ (Corporate Citizenship Report, 2004).

The 2009 BM report produced by the Research and Markets Organization (Guinness Center) shows a different scope of questions touched upon in the process of BM analysis. First of all, attention is paid to business overview, consideration of business segments, products and services of Diageo. Regional Performance is also included as a benchmark. Analyzing this information it is appropriate to have a look at the share of Diageo’s premium brands occupied in the world market. Figure.26 shows this data.

The BM market share occupied by Diageo plc compared to other world-famous beverage manufacturers can be seen on Figure.27

Pricing strategies and global distribution of Diageo products on the basis of pricing considerations can be seen on Figure.28

Financial performance is also one of the major aspects paid particular attention to in the course of BM analysis: here the main points for consideration are annual and quarterly performance, revenue, comparative strength and stability analysis, comparative stock performance, earnings estimates and recommendations (Diageo plc – Competitive Benchmarking Report, n.d.).

Further the report concerns ratio analysis. The first point of analysis is valuation – in this respect Figures.29, 30 and 31 are highly expressive on the main valuation variables.

Growth ratios, financial ratios and profitability ratios are also evident from these figures giving a better understanding of the company’s current situation. Management effectiveness is another ratio analysis variable having high importance in the scope of Diageo BM analysis. M&A developments, business and marketing strategies are the following topics for discussion in the 2009 BM report (Diageo plc – Competitive Benchmarking Report, n.d.). It goes without saying that Diageo is undertaking these types of activities, as it has been stated in the previous section concerning the growing sales of Diageo plc at the US market and a set of developing markets.

Application of the Integrated BM Model to Analyze Diageo BM Techniques

Having reviewed different approaches to BM used in different years of BM research in Diageo it is possible to make an inference that the scope of study adopted by different organizations varies considerably. Besides, it is clear that with the evolution of BM research a number of new benchmarks, variables and indicators have been added to the whole research framework. Each report is informative and useful in its own way, but it is surely possible to find certain gaps that the model integrated in the course of the present research considers more efficiently.

The BM analysis characteristics included into our model from the SCOR model presuppose a much wider scope of BM study. First of all, the model taken into consideration not only its own characteristics but the ones of the supplier, customer and further links of the supply chain, i.e. the suppliers of the company’s suppliers and the customers of the company’s customers. Thus, a much broader scope of elements should be included into the BM analysis of Diageo plc. Among these elements one should have included customer satisfaction, supplier satisfaction, complains and return rates etc. This information would give a fuller idea about comparative advantages or gaps in Diageo plc.

Six sigma approach together with its methodologies, DMAIC and PDCA, also presuppose a certain set of actions directed at implementing improvement in the structure and processes of Diageo plc. Nonetheless, having reviewed the information available for broad usage, it is obvious that Diageo did not extend the BM research to analysis of processes and innovation measures taken within its various departments and finally results that have been achieved. Major attention is paid only to the figures but the way they have been achieved, reduced or raised, is left without attention.

Lean management is paid enough attention to in the process of benchmarking compliance of Diageo plc with environmental requirements and standards. Six sigma approach included into our integrated model does not seem to be appropriate for the BM analysis of Diageo. Taking into consideration the peculiarities of usage of six-sigma in the process of manufacturing involving the product’s composition out of many composite parts, it turns out that beverage/spirits production is not the case.

Finally, adopting the EFQM model elements to the BM analysis of Diageo plc, one is likely to work out a strict and unaltered set of variables according to which BM analysis should be structured and analyzed. As a result of analysis of two Diageo BM reports it has become clear that there is still no unified analysis framework and BM metrics, which may be wonderfully fixed with the help of standardization offered by EFQM.

Implication

Benchmarking indisputably turns out to be an economic activity being paid continuous attention to in Diageo plc. 2003 BM reports already showed particular care about corporate responsibility which is an essential aspect of every company’s functioning because of its reputation and popularity with customers depending on this variable. Besides, the company has been actively developing, extending its activities to other markets and expanding the range of its products, which could not help assisting the success achieved in the world market.

Diageo plc pays particular attention to pricing which could not have successfully worked out without thorough consideration of market opportunities and policies of other companies. BM reports dedicated to organizational activities of Diageo plc also reveal the special care for and consideration of all human resources issues and labor indicators that are highly eloquent in the current BM information analysis.

The fact that Diageo plc takes BM activities seriously and implements their findings constructively goes without saying. To prove this point, it is enough to recollect the latest innovation adopted by Diageo plc with the purpose of having “real-time actionable intelligence for transparency of performance and consistent communication and transparency of status” (Diageo Beefs up Perfect Plant Program with Manufacturing Intelligence Solution, 2009). The representatives of Diageo plc specializing in supply-related Diageo activities assumed that this innovation called Informance (Manufacturing Intelligence Solution) has been taken up in the pursuit of “best-in-class manufacturing performance” (Diageo Beefs up Perfect Plant Program with Manufacturing Intelligence Solution, 2009).

The Informance IMPACT is stated to bring potentially huge profit for Diageo due to its unusual, innovative approach to decision-making concerning business operations planned. This application

“develops action plans based on probability of success. This approach ensures that the manufacturer focuses on those improvements that deliver the greatest impact in consideration of investment and resources” (Diageo Beefs up Perfect Plant Program with Manufacturing Intelligence Solution, 2009).

The main objective Informance aims at accomplishing is continuous improvement, manufacturing flexibility, increased customer value (Diageo Beefs up Perfect Plant Program with Manufacturing Intelligence Solution, 2009). Besides, its value is in its compliance with the latest BM metrics stipulated for food and beverage manufacturers. Thus, it is considered highly helpful for the financial gains resulting from improvement made possible with the help of Informance. According to the opinion of researchers, this opportunity is highly possible and beneficial for Diageo:

“In Informance benchmark studies, researchers use many months of real-time manufacturing performance data aggregated using the Informance Enterprise Manufacturing Intelligence platform. The highly granular and rich real-time nature of Informance EMI adds a new dimension for external and internal benchmarking activities, the solution provider said” (Diageo Beefs up Perfect Plant Program with Manufacturing Intelligence Solution, 2009).

It is not implemented to the fullest extent yet, but it seems to be essential for the continuous improvement process in Diageo. Anyway, it helps us understand that supply chain BM occupies of the central places in Diageo, which is a positive finding that may assist in the verification of results of our research. The Diageo management has adopted a prompt, constructive response on the BM findings in their sector. Hence, it is possible to suppose that the newly discovered BM information suiting the profile of Diageo and a set of ways of BM techniques improvement that have been worked out in the process of the present research may appear highly helpful for Diageo on its way to best-in-class performance on all organizational levels.

Conclusion

Summary

The present research shed light on many strong and weak aspects of the BM process in the UK manufacturing sector, giving a broader and more detailed outlook at the peculiarities, hidden challenges and potential return of the BM research. BM surely occupies an important place in the process of any company’s functioning, be it a service company or a manufacturing enterprise. The innovativeness of approach can be seen in erasing boundaries and daring to accept other specialists’ opinion in the same sphere, which is clearly a breakthrough.

It is enough to recollect the way business affairs used to be conducted several decades ago – R&D departments could become adequate rivals with the national intelligence offices in their effort to keep the whole business process, peculiarities of production, management, marketing, product formula and other ingredients of success top secret. Every company’s being isolated and mysterious for its competitors was number one priority, thus denying any opportunity for sharing or learning experience.

Nowadays the change in perception has come and advantages of joint action on improvement are evident. BM is one of the first steps on the way to continuous innovation with wise and comprehensive consideration of weak and strong sides of one’s own business and their combination with experience taken from competitors on a reciprocal basis.